High-power efficient motor used for electric vehicle

A high-power, electric vehicle technology, applied in the direction of electric vehicles, motors, vehicle components, etc., can solve the problems of insufficient power, insufficient torque, low utilization rate of motor materials, etc., and achieve optimal magnetic circuit distribution, large speed and power span Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

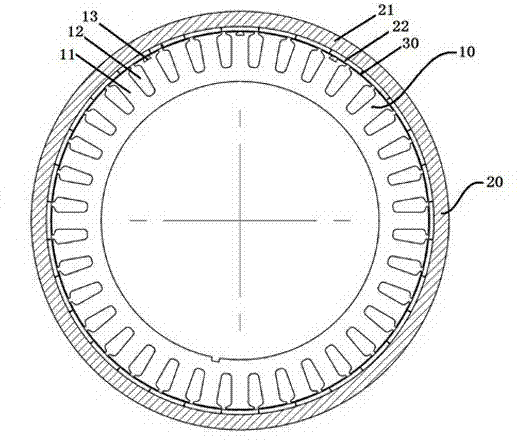

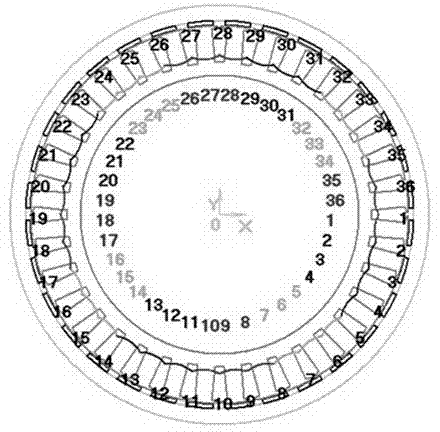

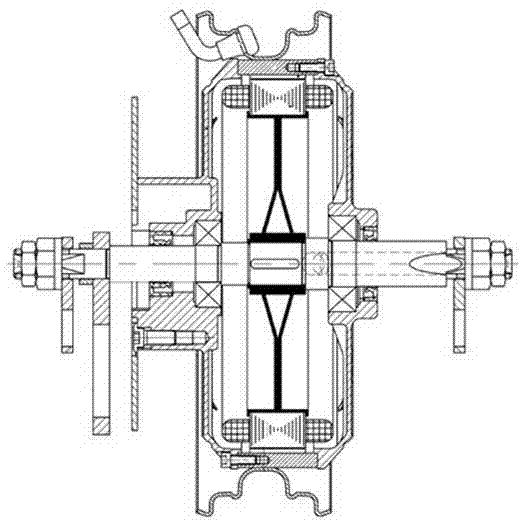

[0015] as attached figure 1 As shown, the high-power and high-efficiency motor for electric vehicles includes a stator 10 and a rotor 20; the stator 10 includes a plurality of silicon steel sheets 11 formed by stamping and stacking each other, and a large pear-shaped stator is arranged in the silicon steel sheets 11 The tooth slot 12, the large pear-shaped stator slot 12 is provided with a stator winding (not shown in the figure); the rotor 20 is provided on the outside of the stator, and the rotor includes a rotor rim 21, and adhesive A plurality of concentric tile-shaped magnetic steel sheets 22 knotted on the inner side of the rotor rim, and an air gap 30 is formed between the magnetic steel sheets 22 and the silicon steel sheet 11; Hall grooves are reserved on the silicon steel sheet 11 13. A Hall element (not shown in the figure) is placed in the Hall slot. as attached figure 2 As shown, the number of the concentric tile-shaped magnetic steel sheets is 32, and the 32 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com