Adhesive film having good machinability for protecting the surface of semiconductor wafer

An adhesive film, semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, film/sheet adhesives, etc., can solve the problems of wafer bending and inability to ensure dicing, and achieve bending phenomenon prevention and resistance. sex-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation method of adhesive film for wafer surface protection

[0037] The present invention provides a method for preparing an adhesive film for protecting the surface of a semiconductor wafer, which is characterized in that it comprises: a step of forming a substrate film; a step of controlling the tensile strength and elongation at break of the substrate film; A step of forming an adhesive layer on one surface; and a step of ultraviolet curing the substrate film on which the adhesive layer is formed.

[0038] The process of forming the base film includes an extrusion process, an ultraviolet curing process, a casting process, a calendering process, a thermal curing process, and the like.

[0039] Preferably, an acrylic film is formed by ultraviolet curing, an ethylene-vinyl acetate copolymer film and a polyolefin film are formed by an extrusion process, and a polyurethane film is formed by a thermal curing process. And, a polyvinyl chloride film is formed through ...

experiment example 1

[0055] Experimental Example 1: Cutting property of substrate film and measurement of cutting property

[0056] Examples and Comparative Examples

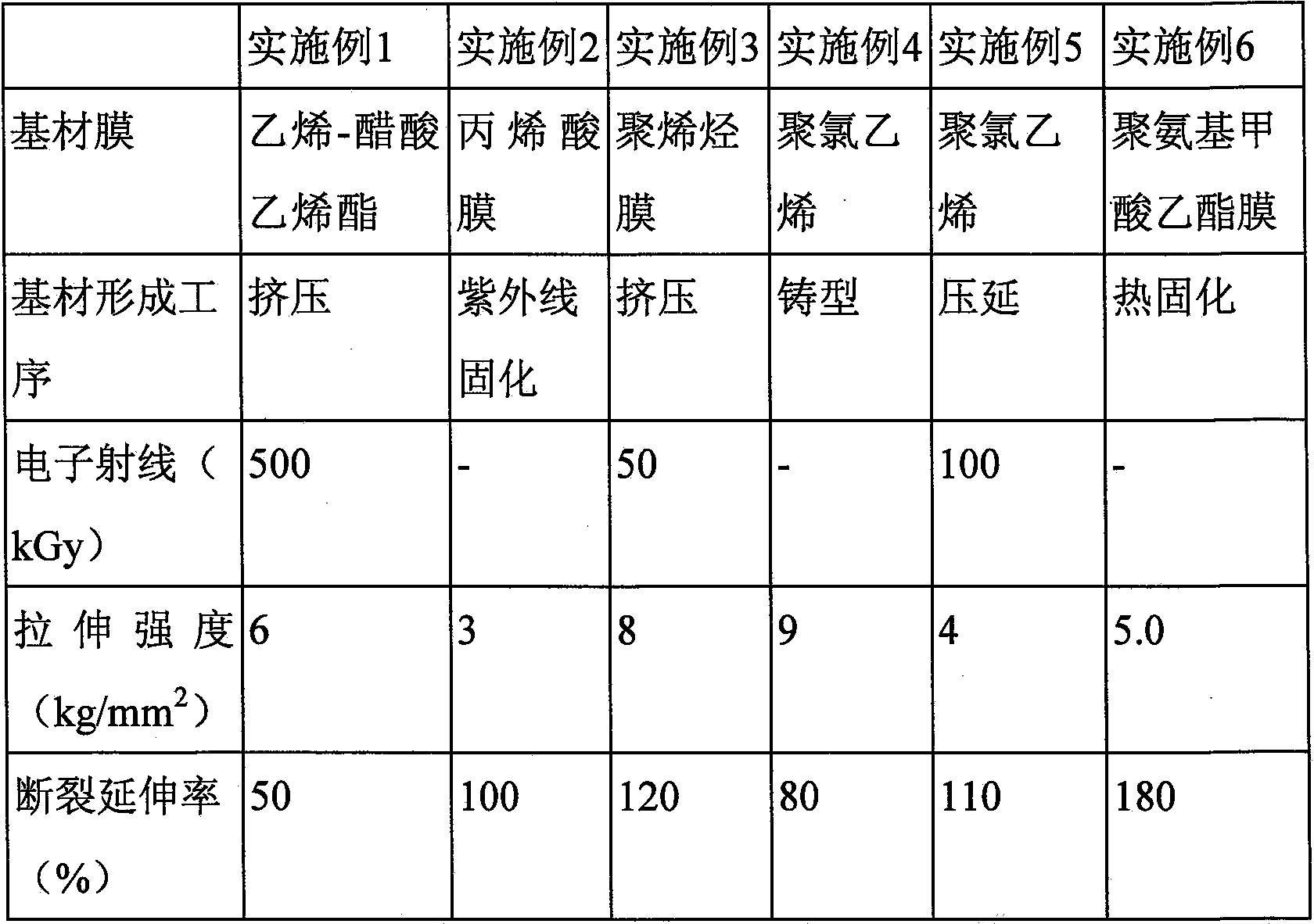

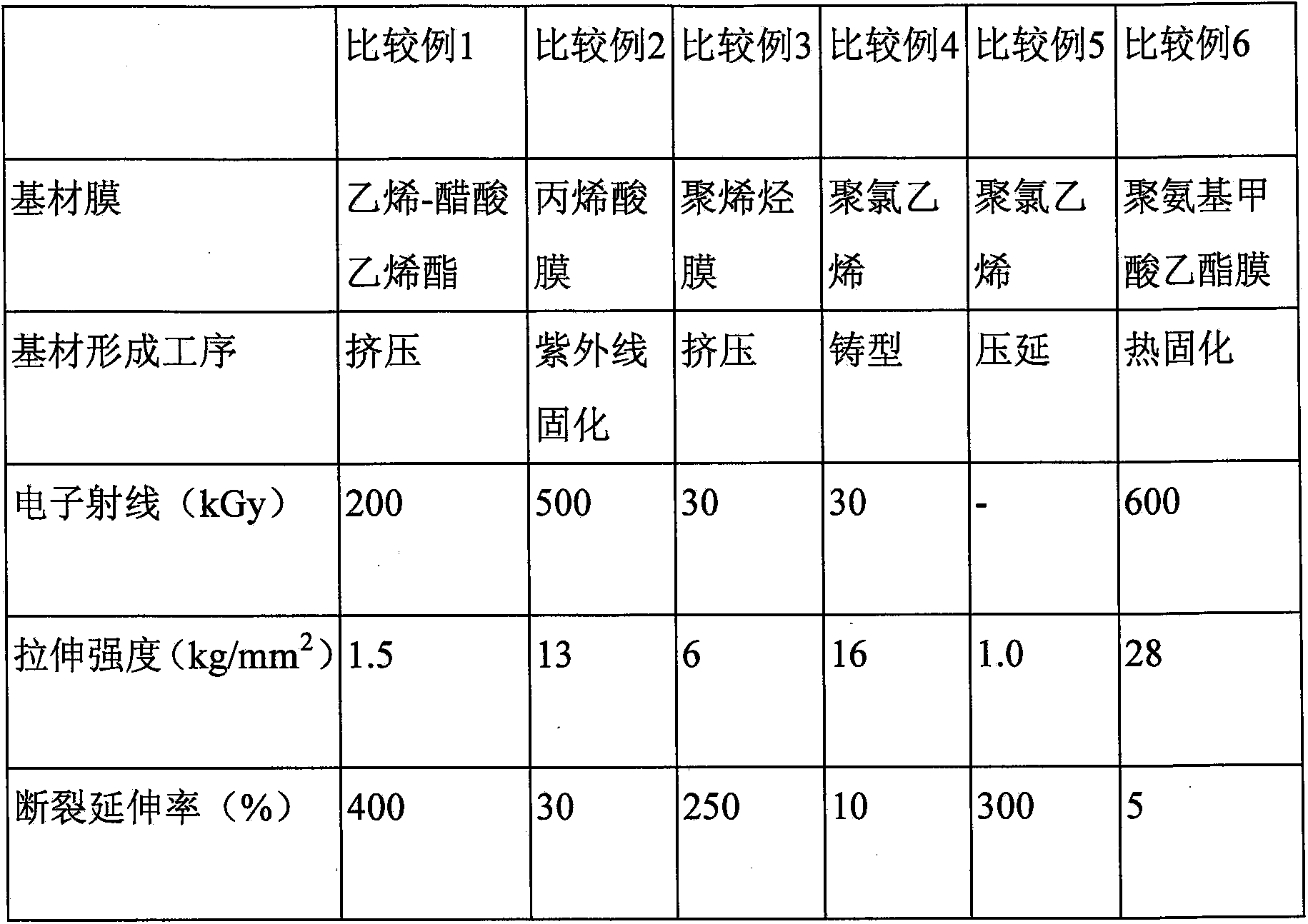

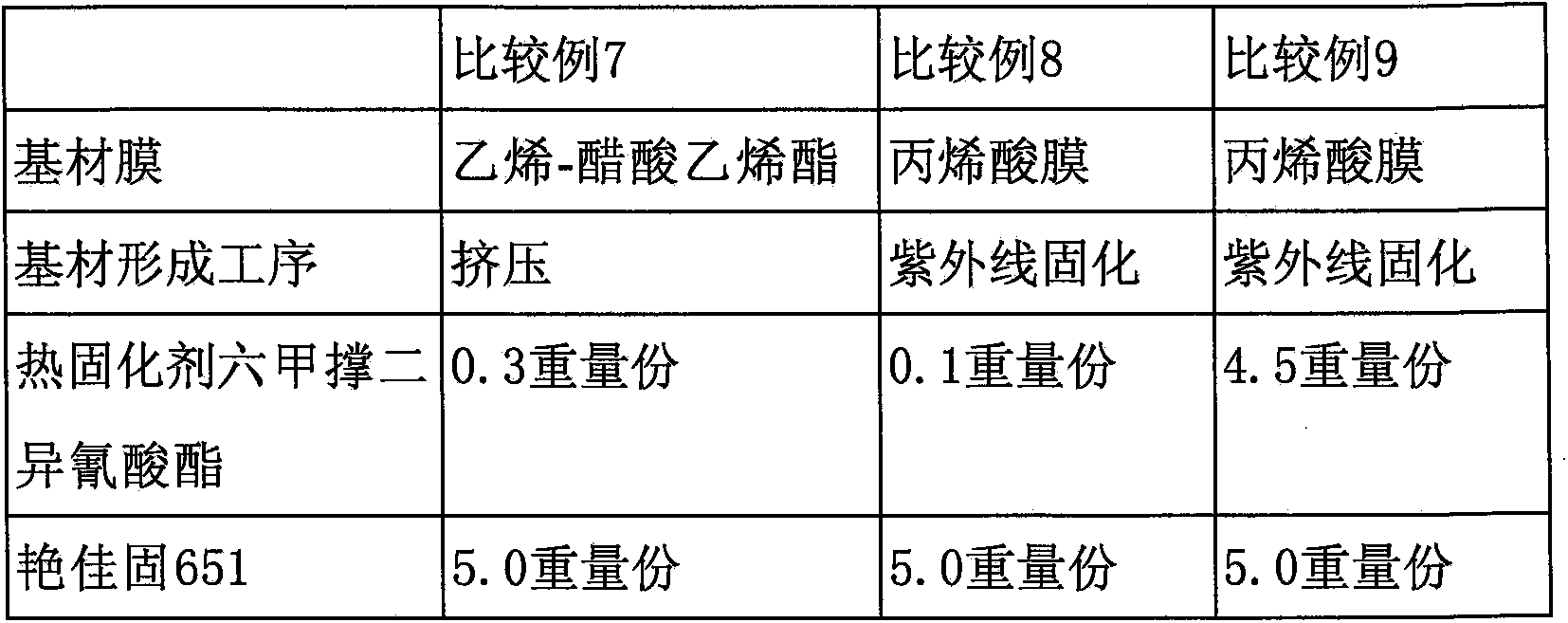

[0057] In Table 1 and Table 2 below, different types of base films are used, and the tensile strength and elongation at break are controlled to be different according to the process of forming the base film to measure the cuttability and cutability of the above base film. .

[0058] Table 1

[0059]

[0060] Table 2

[0061]

[0062] Evaluation method

[0063] Prepare the base film of the above table 1 and table 2 with a thickness of 100um into a size of 5cm x 1cm horizontally and vertically, clamp the upper part and the lower part with jigs in a tensile testing machine, and place them on a load cell (10ad cell ) Tensile test was carried out under a load of 30 kg. In this case, the horizontal axis represents the distance (distance), and the vertical axis represents the elongation at break shown by the force curve (curve),...

experiment example 2

[0073] Experimental example 2: Determination of the gel content of the adhesive layer and the peeling force of the adhesive film

[0074] Examples and Comparative Examples

[0075] As shown in Table 5 and Table 6, base films were formed according to different types, and an adhesive layer was formed on one side of the formed base film by the comma coating method. The above-mentioned adhesive layer includes an acrylic resin composition, and the composition of the above-mentioned acrylic resin composition is, relative to 100 parts by weight of the total amount of the acrylic resin composition, 60 parts by weight of ethylhexyl acrylate, 20 parts by weight of methyl acrylate , 20 parts by weight of hydroxyethyl acrylate. Afterwards, above-mentioned resin composition is mixed in solvent ethyl acetate, after dropping into as thermal initiator azobisisobutyronitrile (2,2-azobisisobutyroni-trile, AIBN Japan) 0.01 weight part with respect to resin composition total amount, The tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com