Crystallizer casting powder for high-aluminum steel continuous casting

A technology of mold powder and high-aluminum steel, which is applied in the field of mold powder for continuous casting of high-aluminum steel and slab continuous casting of high-alumina steel ([Al]=1%~3.5%) steel grades, It can solve the problems of increasing continuous casting production cost and high O content, and achieve the effects of low cost, reduced reactivity and strong capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below with examples. These examples are only descriptions of the best embodiments of the present invention, and do not limit the scope of the present invention in any way.

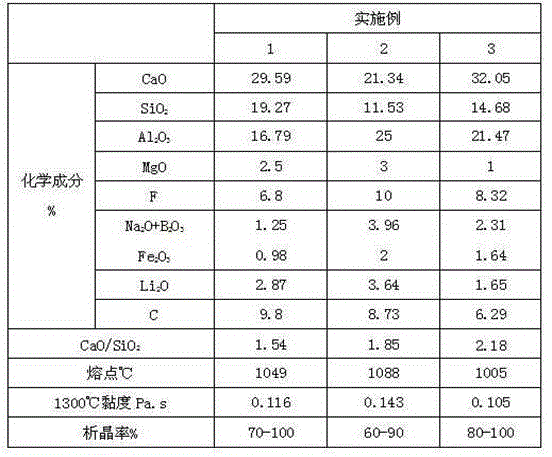

[0017]The mold mold powder for continuous casting of high-alumina steel in the present invention is prepared from wollastonite, limestone, quartz sand, fluorite, bauxite, magnesia, anhydrous borax, lithium carbonate and carbonaceous materials as raw materials. Its chemical composition satisfies by weight percentage: SiO 2 :10~25%, Al 2 o 3 : 12~25%, CaO: 15~35%, MgO: 1~3%, F: 6~10%, Na 2 O+B 2 o 3 ≤3%, Li 2 O:1~4%, Fe 2 o 3 ≤2%, C: 5~10%, and the rest are impurities.

[0018] The physical and chemical properties of the high aluminum steel continuous casting mold flux of the present invention are: CaO / SiO 2 It is 1.5-2.2, the melting point is 1000-1100°C, and the viscosity is 0.09-0.15Pa·s at 1300°C.

[0019] Table 1 lists the weight p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com