Split electrode electrosparking method and adopted split electrode

A processing method and EDM technology, applied in the field of split electrodes, can solve the problems of high technical difficulty, high scrap rate, tool rigidity and space limitation, etc., and achieve the effect of simple processing trajectory, guaranteed processing accuracy, and reduced programming difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

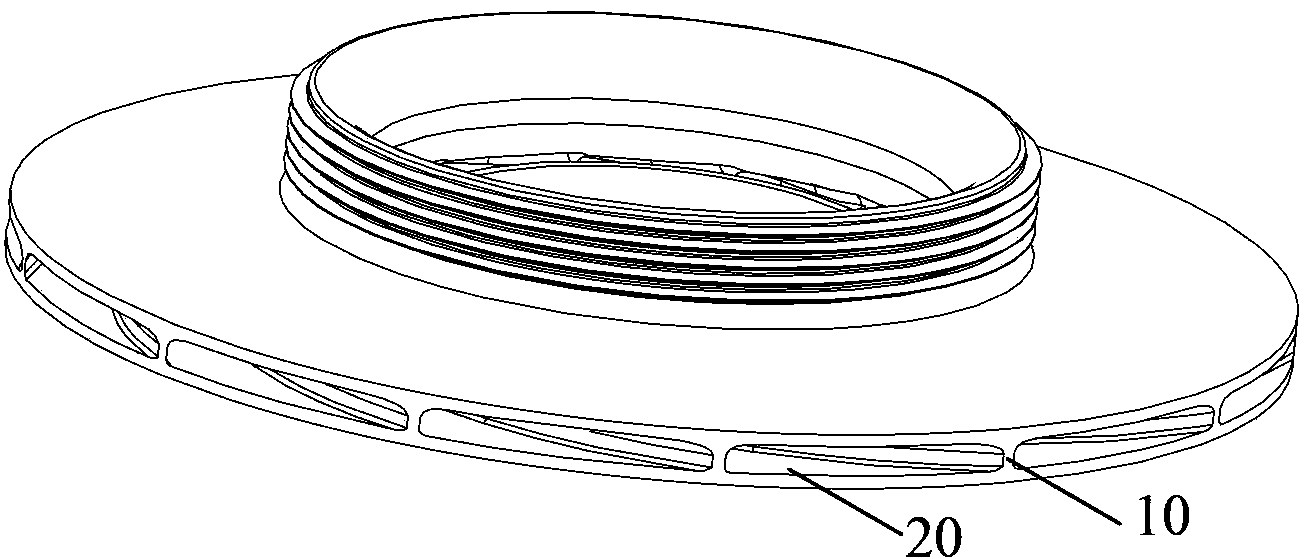

[0029] EDM uses the instantaneous high temperature generated by the discharge to melt the surface of the workpiece opposite to the electrode, and gradually remove the material to achieve the purpose of processing. Therefore, this embodiment adopts the split electrode EDM method to prepare the integral closed impeller, so as to figure 1 The overall closed impeller structure shown is taken as an example to describe the specific implementation of the split electrode electric discharge machining method.

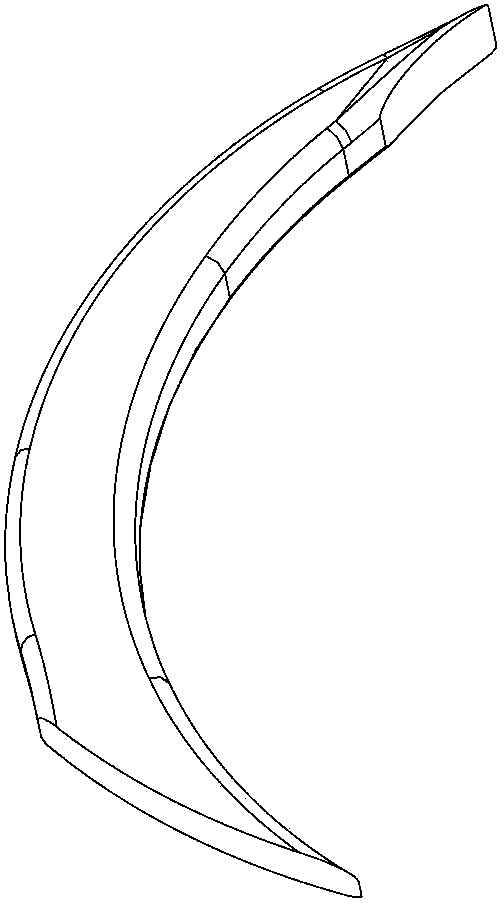

[0030] First, according to figure 1 The internal cavity structure of the overall closed impeller shown, that is, the shape and size, is extracted as figure 2 The three-dimensional model of a single flow channel inside the overall closed impeller shown, the single flow channel is figure 1 As shown in , the single flow channel 20 between two adjacent blades 10; because the shape and size of the multiple flow channels inside the integral closed impeller are exactly the same, so e...

Embodiment 2

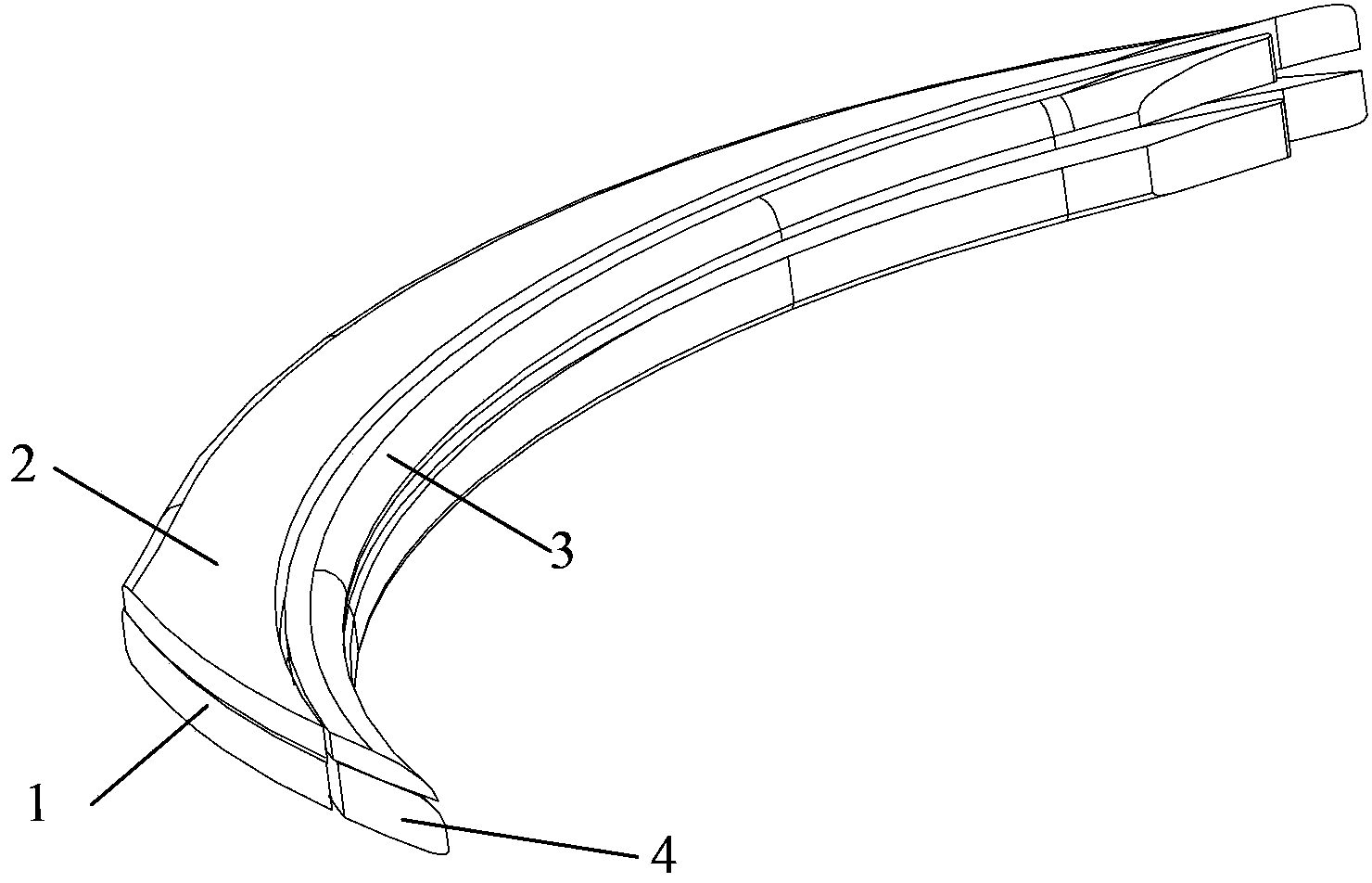

[0038]This embodiment provides a split electrode used in Embodiment 1. The split electrode includes a plurality of single electrodes, and the number of single electrodes is equal to the number of modules formed by dividing the three-dimensional model of a single flow channel. A single electrode is divided into modules by EDM and its corresponding single flow channel. On the premise that there are four flow channel modules in Example 1, this embodiment sets the single electrode to four, and the four single electrodes correspond to the processing The four modules split by the single-channel 3D model. The four single electrodes are processed according to the characteristics of the flow channel cavity, and the external contour surface of the entity composed of all the single electrodes is highly consistent with the cavity of the closed impeller flow channel.

[0039] Corresponding to the four modules in Embodiment 1, there are four single electrodes, namely the first electrode, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com