Numerical control drilling machine and numerical control drilling method

A drilling method and drilling rig technology, applied in metal processing and other directions, can solve problems such as service life impact, numerical control drilling rig difficulty, PCB board adhesion, etc., and achieve the effect of prolonging service life and preventing adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

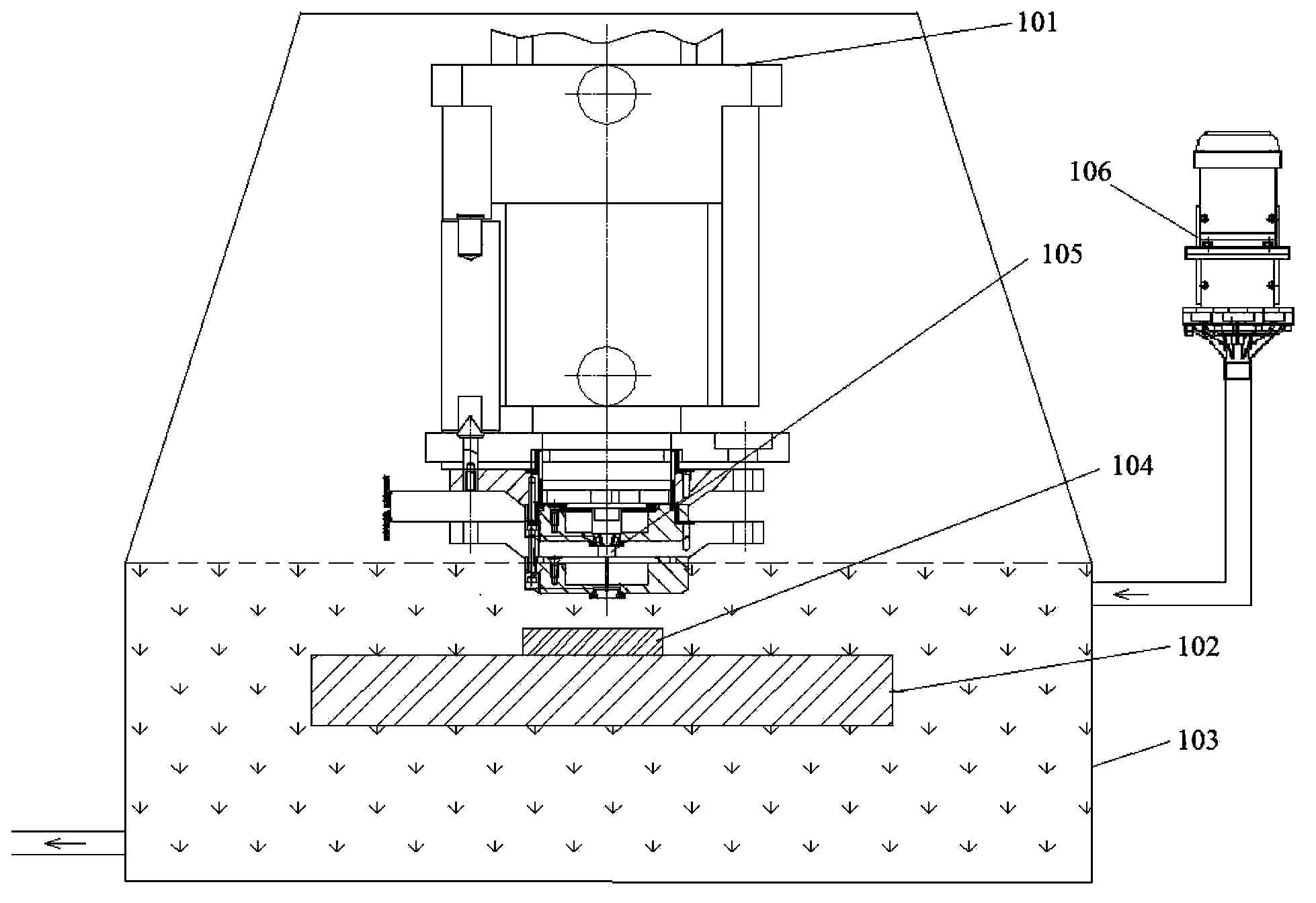

[0024] This embodiment provides a kind of numerical control drilling machine, comprises drilling machine 101 and is used to place the drilling workbench 102 of panel 104, is provided with cooling groove 103 below described drilling machine 101, is provided with in the described cooling groove 103 and is used for cooling. liquid, the drilling table 102 is placed in the liquid in the cooling tank 103 .

[0025] In this embodiment, the board 104 may be a PCB, or other boards 104 that need to be drilled, and there is no special limitation here. When using the numerical control drilling machine for drilling, the plate 104 is fixed on the drilling table 102, and the drilling table 102 is placed in the liquid in the cooling tank 103, and then the drilling machine The drill bit 105 of 101 extends under the liquid surface to drill holes on the plate 104 placed in the liquid. The heat generated by the drilling will be absorbed by the liquid in the cooling tank 103 , thereby reducing th...

Embodiment 2

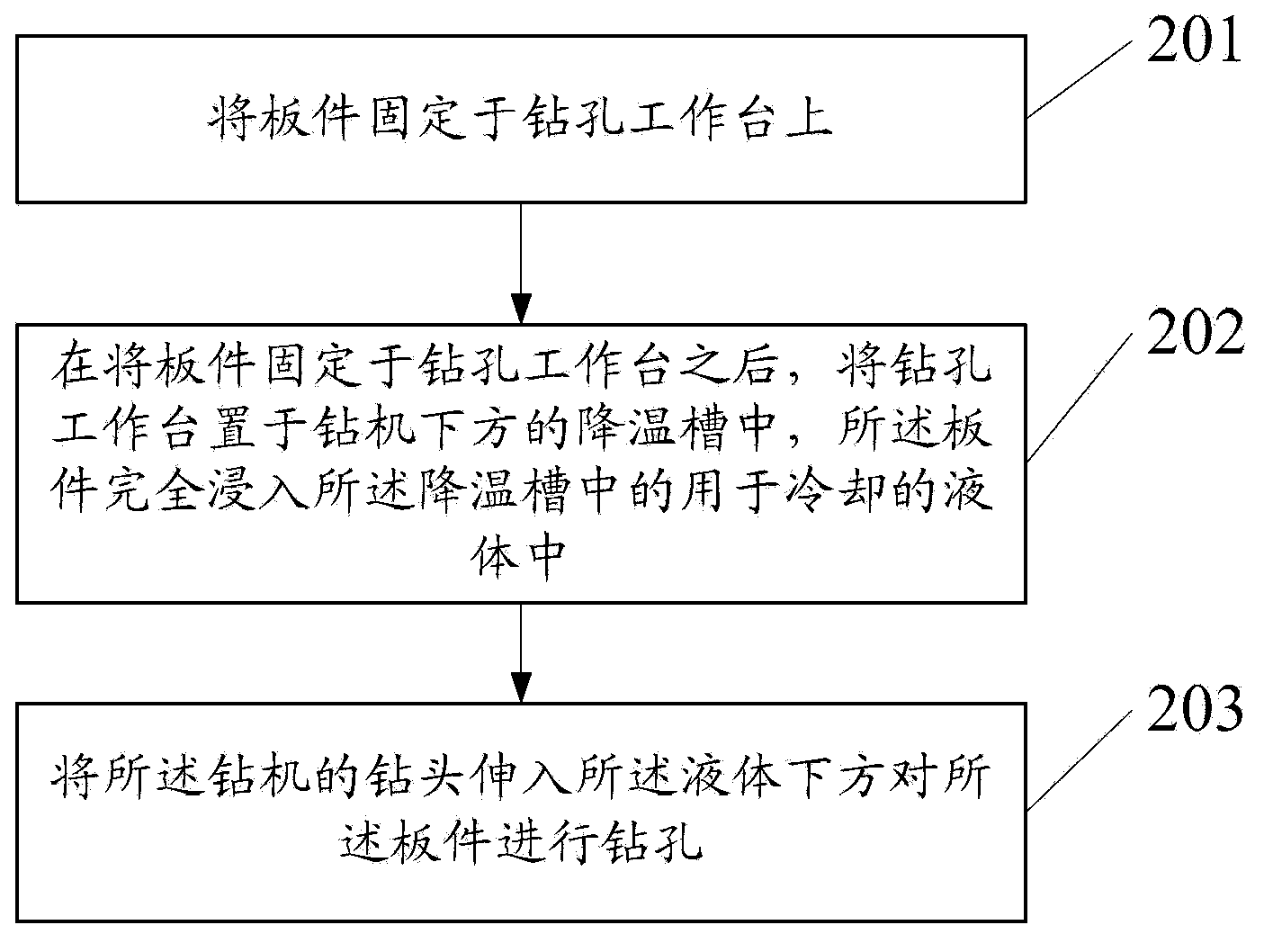

[0033] Such as figure 2 As shown, the present invention also provides a kind of numerical control drilling method, comprising:

[0034] 201. Fix the plate on the drilling table;

[0035] 202. After the plate is fixed on the drilling table, the drilling table is placed in the cooling tank under the drilling machine, and the plate is immersed in the cooling liquid in the cooling tank;

[0036] 203. Extend the drill bit of the drilling machine under the liquid to drill holes in the plate.

[0037] In this embodiment, the liquid may be cooling water or frozen water. After the plate is immersed in the liquid, and then the plate is drilled, the liquid can take away a large amount of heat generated by drilling, thereby reducing the temperature of the drill bit and the plate. In addition, the dust generated by drilling will stay in the liquid to avoid polluting the space environment.

[0038] In order to better solve the technical problems of the present invention, on the basis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com