Granular paraffin conveyor belt

A conveyor belt and paraffin technology, applied in the field of granular paraffin conveyor belt, can solve the problems of energy consumption, secondary pollution of paraffin particles, etc., and achieve the effects of simple structure, convenient use and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

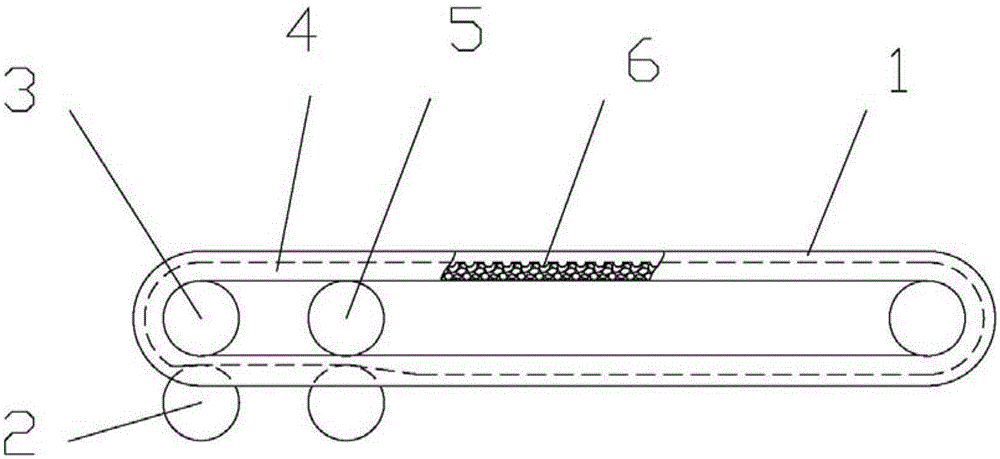

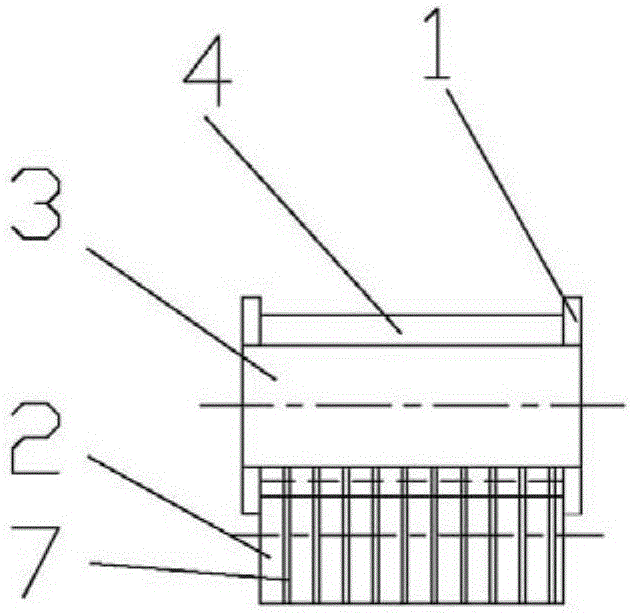

[0016] A paraffin wax conveyor belt, the conveyor belt comprising a conveyor wheel 3 and a conveyor belt body, the conveyor belt body is provided with a water absorption layer 4, the upper surface of the water absorption layer 4 is provided with a number of circular pits 6; two of the conveyor belt body A side baffle 1 is provided on the side; two pressure rollers 2 are provided below the conveyor belt body, the diameter of which is the same as that of the conveyor wheel 3. One of the pressure rollers 2 is located directly below the transfer wheel 3, and an auxiliary roller 5 is provided between the two transfer wheels 3. The surface of the auxiliary roller 5 is in contact with the lower part of the conveyor belt and is located directly below the auxiliary roller 5. There is another pressure roller 2. The pressure roller 2 is provided with a guide groove 7. The water-absorbing layer 4 is made of sponge material. The diameter of the circular pit 6 is larger than the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com