Preparation method of 4,6-dihydroxy-5-methoxypyrimidine sodium

A technology of methoxypyrimidine sodium and dihydroxy, applied in 4 fields, can solve problems such as temperature rise, violent reaction, danger, etc., achieve accurate temperature, increase yield, and suppress side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

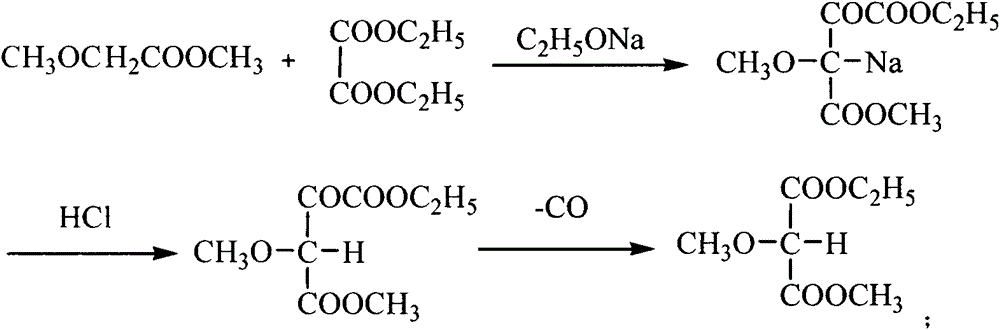

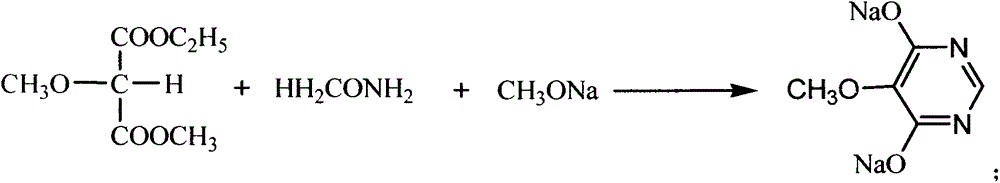

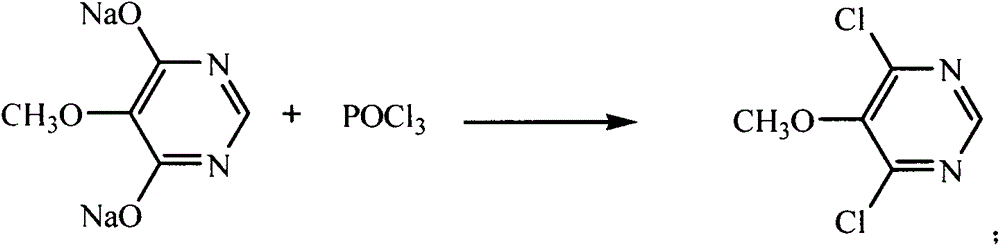

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of 4,6-dihydroxy-5-methoxypyrimidine sodium of the present invention comprises the following steps: (a) putting sodium methoxide into a dry container, stirring and heating to 65-68°C, adding formamide , followed by dropwise addition of methyl ethyl malonate, reacting at 65-70°C for 2-6 hours to obtain the mixture; (b) placing the mixture at 25-80°C to distill off methanol, then cooling to 10-15°C, centrifuge to collect the solid. By adding sodium methoxide and formamide in a dry container, and then adding methyl ethyl methoxymalonate dropwise, on the one hand, it can prevent the remaining moisture in the container from destroying the reaction, and on the other hand, the dropwise addition can effectively It is beneficial to control the addition speed of methyl ethyl methoxymalonate, thereby more accurately controlling the temperature of the reaction, suppressing side reactions, and increasing the yield of the desired product.

[0026] In order to ...

Embodiment 1

[0029] This example provides a kind of preparation method of 4,6-dihydroxy-5-methoxypyrimidine sodium, the specific feeding ratio is shown in Table 1:

[0030] Table 1 Reaction raw materials and their feeding ratio

[0031]

[0032] The specific operation process is as follows:

[0033] (a) First put 830kg of sodium methoxide into a dry ring-closure reaction pot, stir and heat to 65-68°C, add 186kg of formamide, and then evenly add methyl ethyl malonate dropwise, and control the dropping temperature to 65°C. ~70°C, dropwise addition time is 1~1.5 hours. After the dropwise addition is completed, keep the reaction at 65-70°C for 4 hours;

[0034] (b) Distill and recover methanol at normal temperature (25-30°C) for 1-1.5 hours, distill at 80°C for 2-3 hours under reduced pressure until methanol does not come out, then add 500L of water, and recover about 0.5-0.5% of methanol with water under normal pressure About 1 hour, when the temperature reaches 80-85°C, stop the distil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com