Spinning and drawing device

A technology of stretching device and spinning device, which is applied in the direction of stretch spinning, textiles and papermaking, etc. It can solve the problems of filament breakage and fluff, achieve temperature deviation suppression, quality improvement, and suppression of thread breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

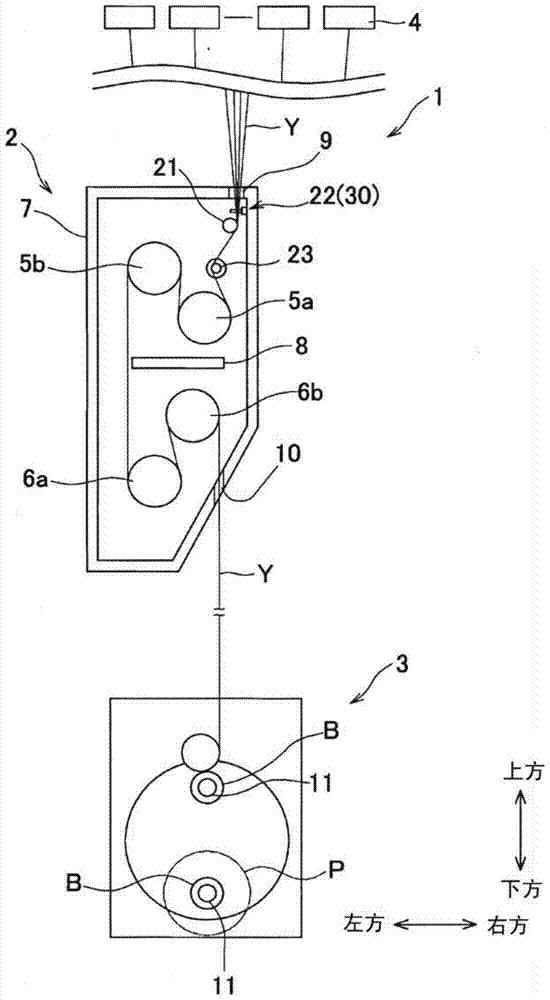

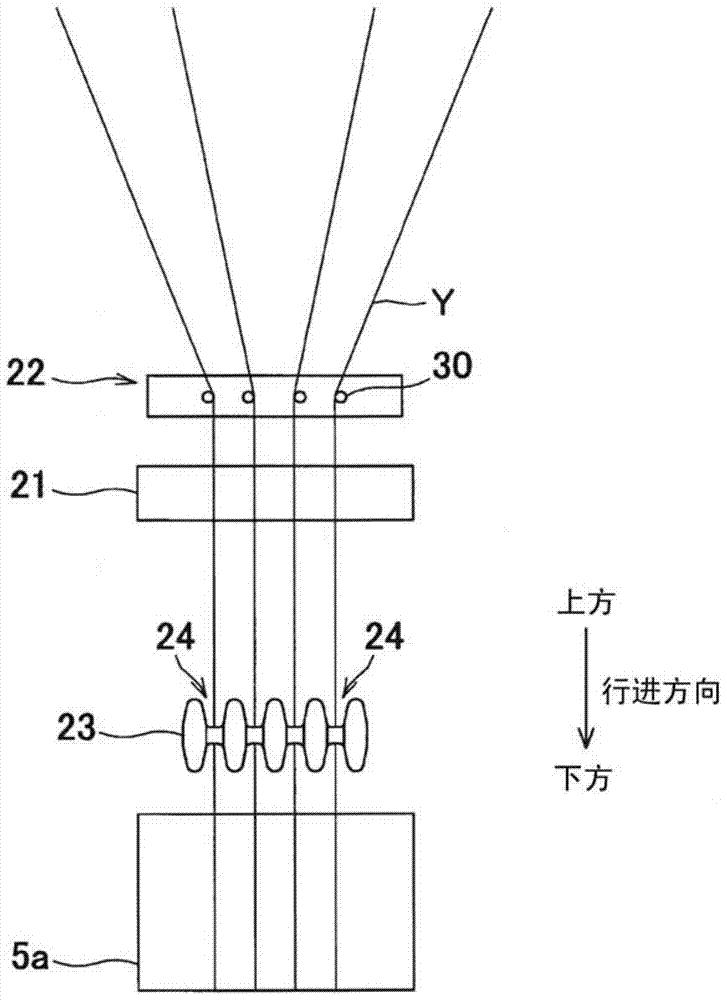

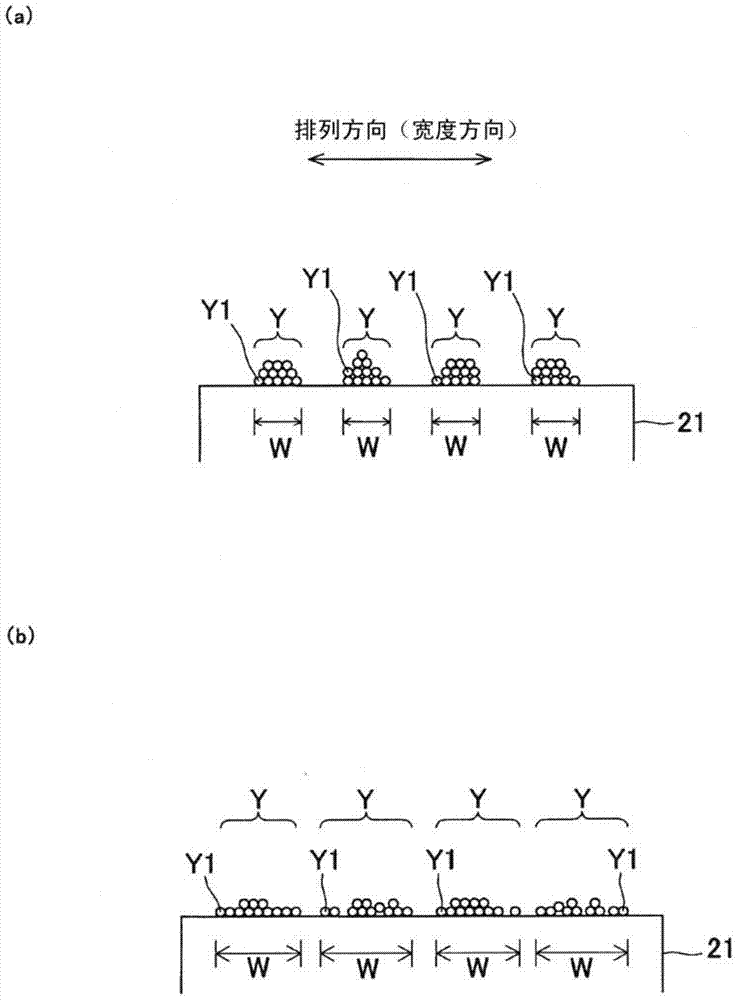

[0051] Embodiments of the present invention will be described below. figure 1 It is a front view showing the configuration of a spinning coiler provided with the spinning and drawing device according to the first embodiment of the present invention. Below, will be in figure 1 The respective directions shown in the diagram are described as the up-down direction and the left-right direction. Such as figure 1 As shown, the spinning winder 1 includes a spinning drawing device 2 and a yarn winding device 3 . The spinning take-up machine 1 uses the spinning drawing device 2 to draw a plurality of multifilaments Y spun from the spinning device 4 located above and supplied continuously, and sends them to the yarn winding device 3, and winds them up with the yarn. The device 3 winds up a plurality of multifilaments Y. The multifilament Y is, for example, a polyester fiber that requires preheating for stretching. One multifilament Y is composed of a plurality of filaments.

[0052...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com