Insulating gas insulation performance experiment system and method applied to electrical equipment

A technology of insulating gas and insulating performance, which is applied in the field of experimental system of new insulating gas insulating performance. tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

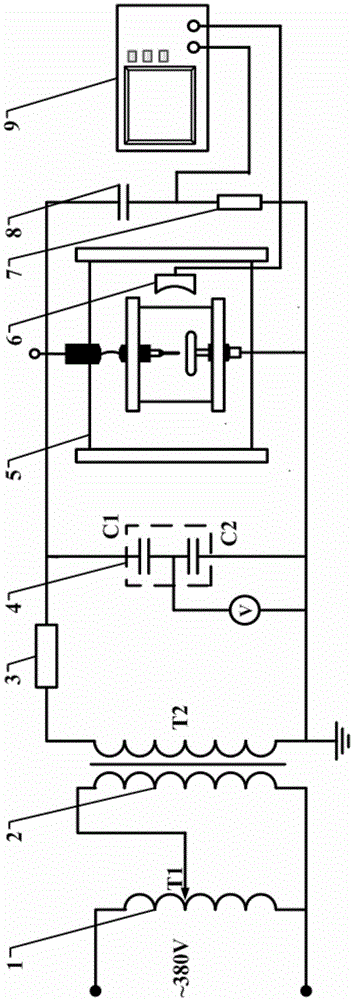

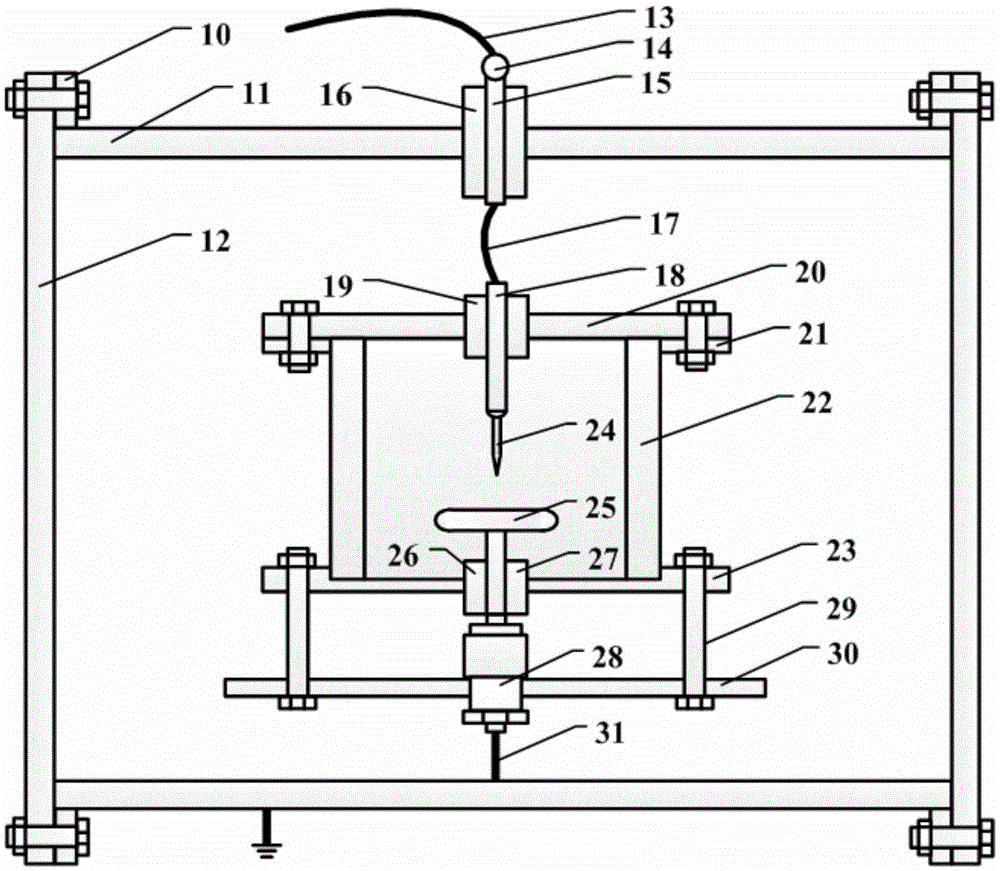

[0037] This embodiment discloses an insulating gas insulation performance test system applied to electrical equipment, including a high-voltage generator, a measuring device, and an insulating gas test device.

[0038] The high-voltage generator includes a voltage regulator 1 , a non-corona test transformer 2 , a non-partial discharge protection resistor 3 , and a coupling capacitor 8 . The primary side of the voltage regulator 1 is connected to the 380V mains through wires, and the secondary side of the voltage regulator 1 is connected to the primary side of the non-corona test transformer 2 through cables. The coupling capacitor 8 has two terminals A and B. After the A terminal of the coupling capacitor 8 is connected in series with the non-discharge protection resistor 3 , it is electrically connected to the high voltage terminal of the secondary side of the non-corona test transformer 2 . After the B terminal of the coupling capacitor 8 is connected in series with the non...

Embodiment 2

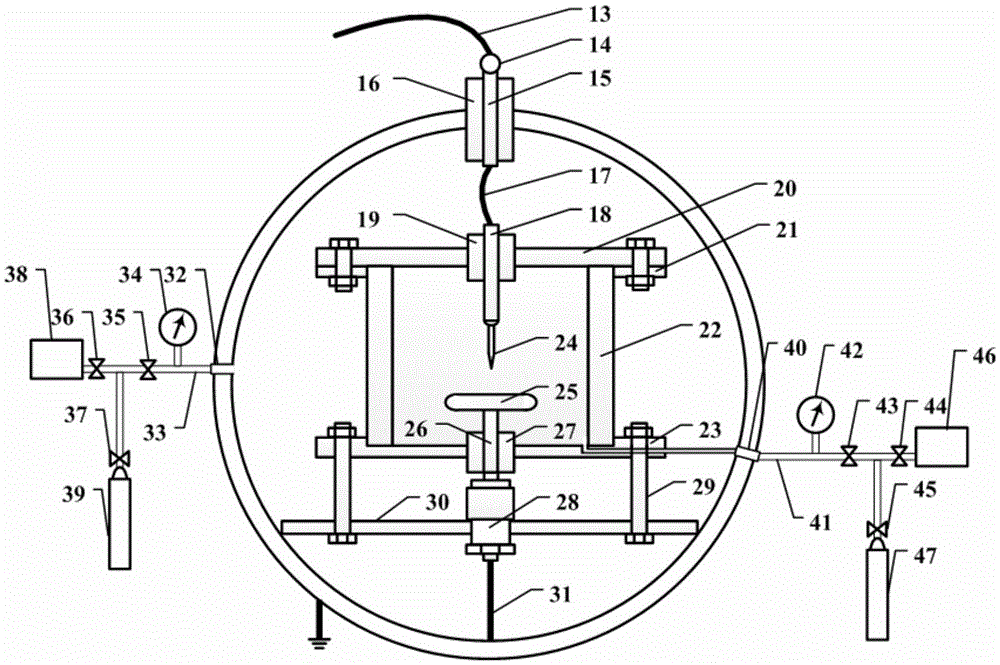

[0048] This embodiment discloses an insulating gas insulation performance experiment system applied to electrical equipment, the main structure of which is the same as that of Embodiment 1.

[0049] In this embodiment, the primary side of the voltage regulator 1 is connected to the 380V mains through a wire, and the secondary side of the voltage regulator 1 is connected to the non-corona test transformer 2 (commercially available product) through a cable. ) primary side connection, the rated capacity of the non-corona test transformer 2 is 60kVA, the high and low voltage winding ratio is 60kV / 400V, and the rated current is 1.0A / 150A. The high voltage end of the secondary side of the non-corona test transformer 2 is connected to the non-partial discharge protection resistor 3 through a cable, so as to perform current limiting protection on the line.

[0050]In the outer tank part of the present embodiment, the outer tank shell 11 is cylindrical stainless steel, and the material...

Embodiment 3

[0060] An insulating gas insulation performance test system applied to electrical equipment is the same as that in Embodiment 1 or 2. The outer tank shell of the gas insulation performance test device has an outer diameter of 450 mm, a thickness of 15 mm, and a length of 650 mm. The outer diameter of the outer tank fixing plate is 500 mm, and the thickness is 15 mm. The outer diameter of the outer tank cover plate is 500 mm, and the thickness is 20 mm. The outer diameter of the screw hole on the outer tank fixing plate and the outer tank cover plate is 25mm. The outer diameter of the insulating sleeve of the outer tank is 40 mm, and the length is 100 mm. The outer diameter of the high-voltage conductive rod of the outer tank is 8 mm, and the length is 150 mm. The outer diameter of the inner tank shell of the gas insulation performance test device is 280 mm, the thickness is 20 mm, and the height is 180 mm. The outer diameter of the fixing plate on the inner tank is 330mm, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com