Production state monitoring system and method

A production status and monitoring system technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems that the historical data of the production line cannot be saved, lean production cannot be achieved, and the efficiency of the production line is difficult to grasp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

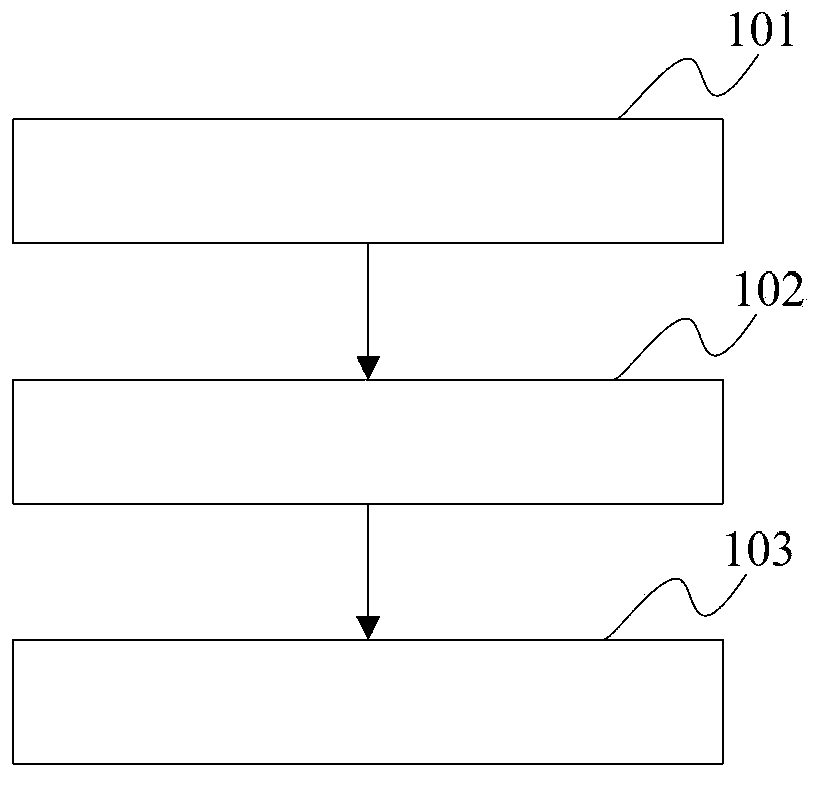

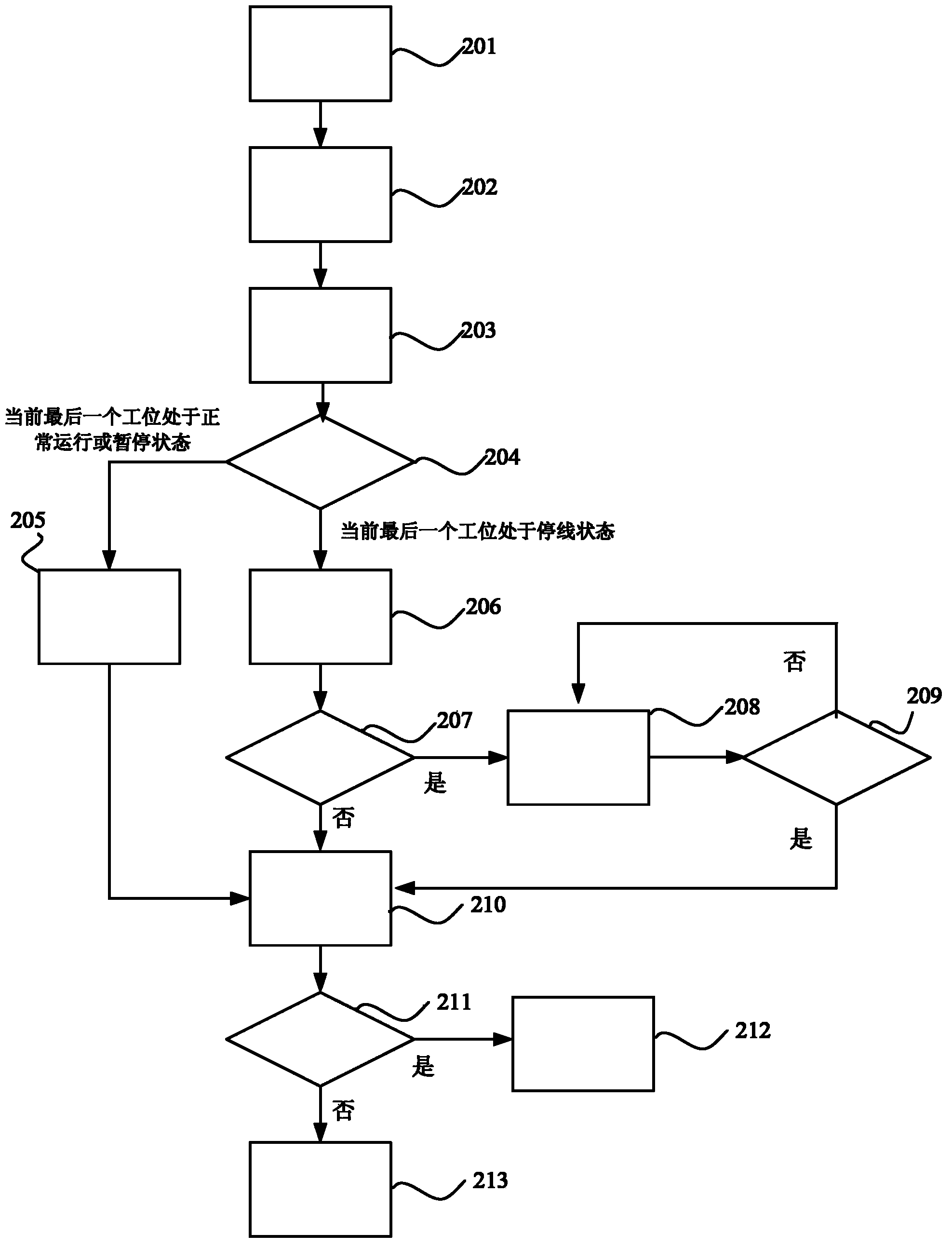

[0085]figure 1 It is an exemplary flow chart of the production status monitoring method in the embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0086] Step 101, receiving product index information of a currently produced product from at least one workstation.

[0087] In a specific implementation, a product production line usually includes at least two stations for flow operation. The product index information of the current production product received from at least one station usually includes the product model and station number. The product model is used to distinguish different models of the same product. For example, A60 ECA 8CH indicates that the finished product needs to be sent to China, while A60 ECA8CH to DE indicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com