Pattern forming method

A pattern and extension direction technology, applied in the field of pattern formation, can solve problems such as line edge distortion of patterns, and achieve uniform arrangement density, improved precision, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

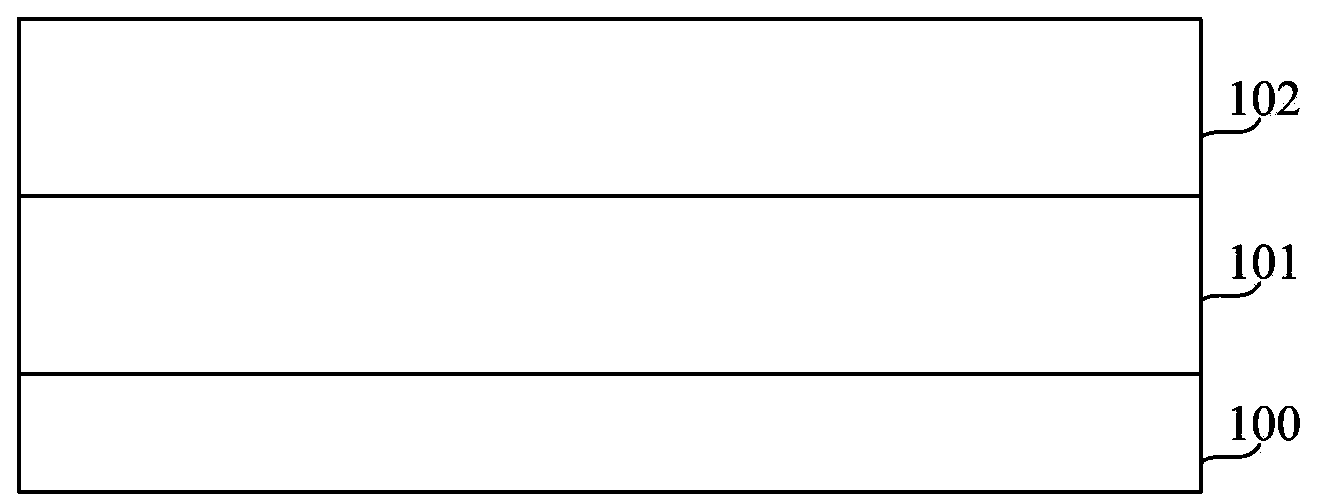

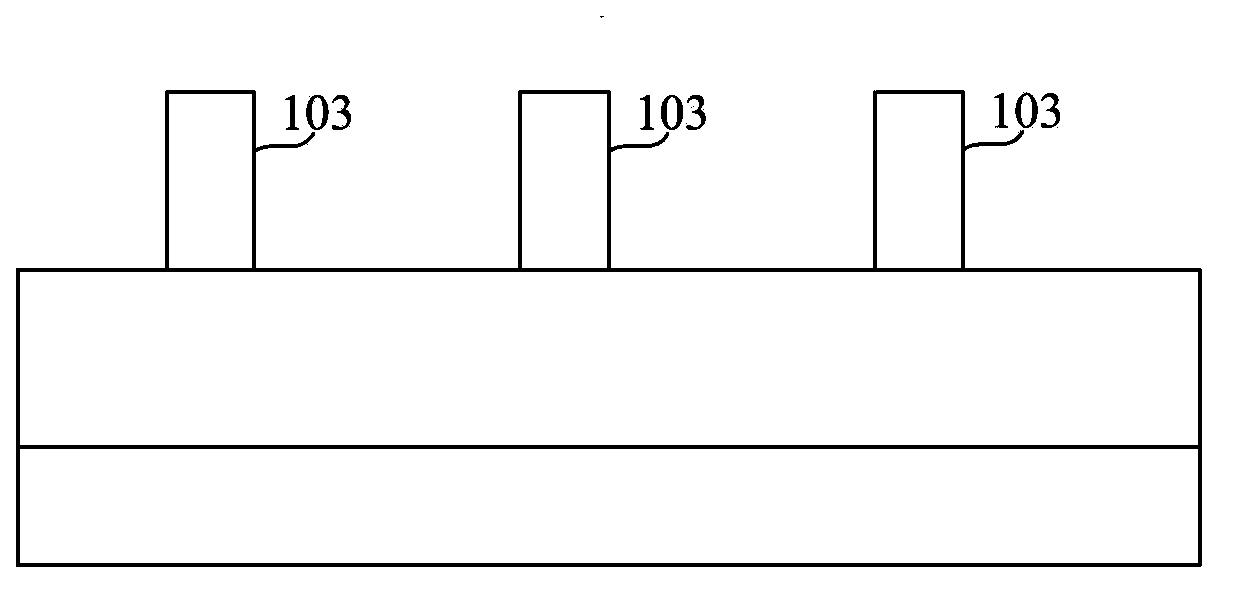

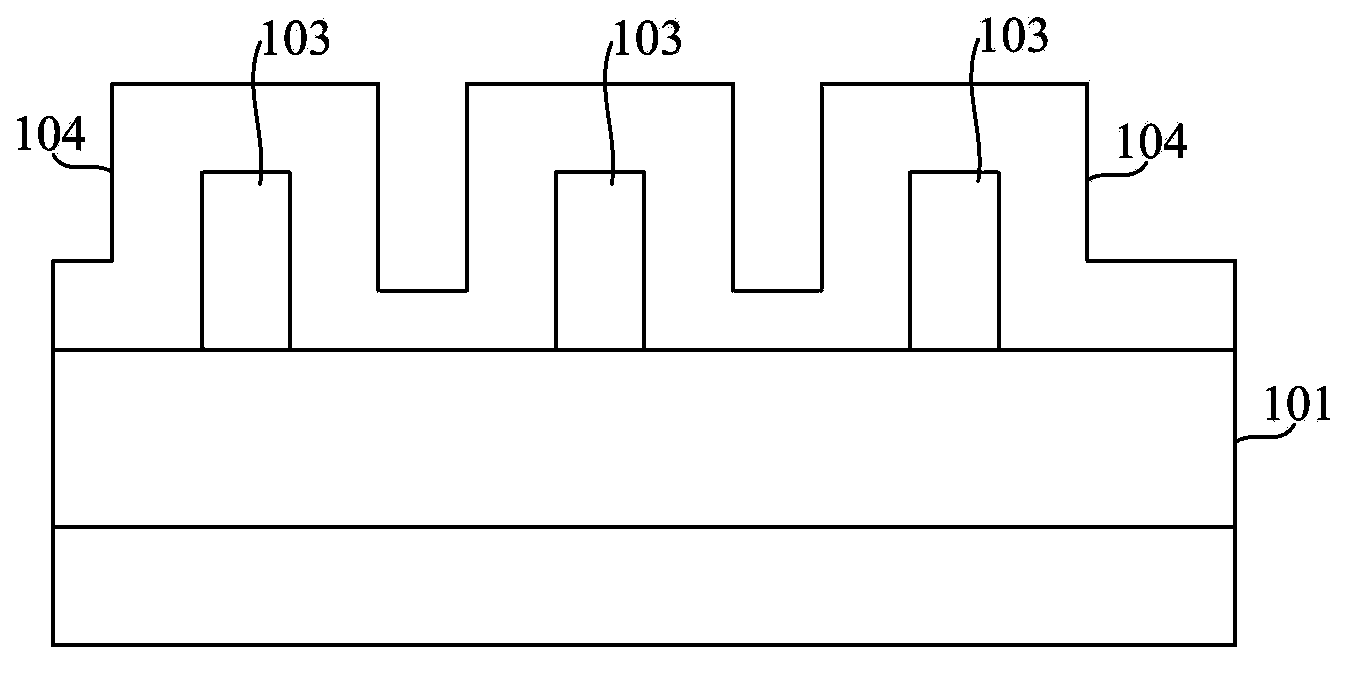

[0054] The inventor has conducted research on the problems existing in the SADP technology of the prior art, and found that: first, refer to Figure 5 and Figure 4, use the sidewall 105 as a mask to etch and remove the sacrificial line 103. In this process, after the sacrificial line 103 is removed, the surface of the sidewall 105 in contact with the sacrificial line 103 has a concave-convex or jagged shape, and the line width roughness (Line Width Roughness, LWR) is higher. If the surface of the sidewall 105 has a concave-convex or jagged shape, when the sidewall 105 is used as a mask to etch the film layer 101 to form the line 106, the concave-convex or zigzag shape of the sidewall 105 in the direction of the extension of the sacrificial line is reflected in the The sidewalls of the wires 106 make the sidewalls of the wires 106 have a concave-convex shape or a zigzag shape. Then, the hole pitch of the pattern including the lines 106 with concave-convex or serrated sidewal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com