Dual in-line package frame

A dual-in-line package and frame technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of poor heat dissipation performance, diameter limitation, insufficient thermal conductivity, etc., to improve the heat dissipation effect, increase the vertical area, The effect of reducing the heat transfer distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to solve the problem of poor heat dissipation, a dual-in-line package frame is proposed to improve the heat dissipation effect.

[0021] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

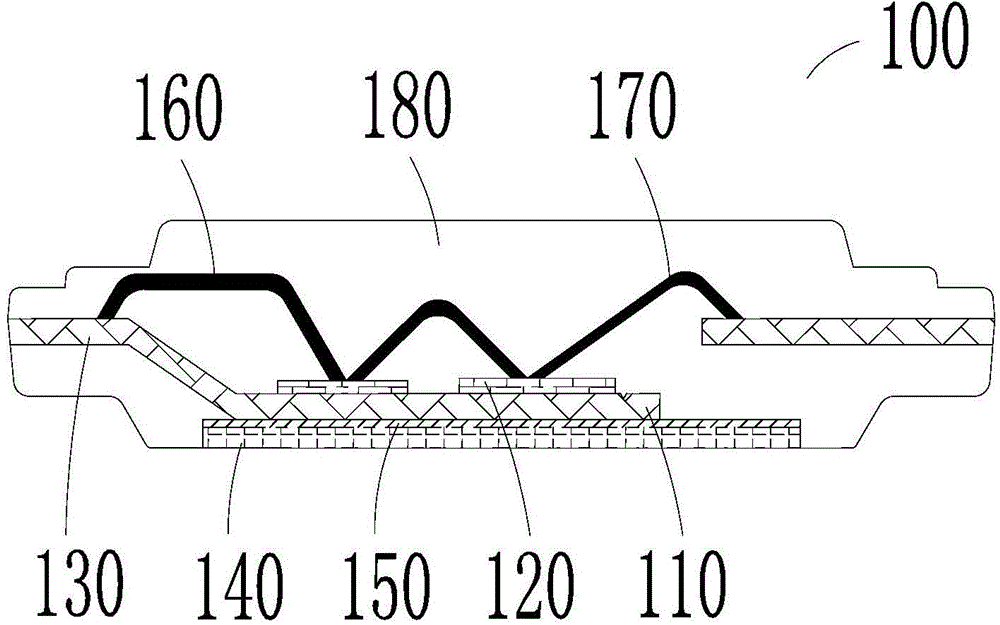

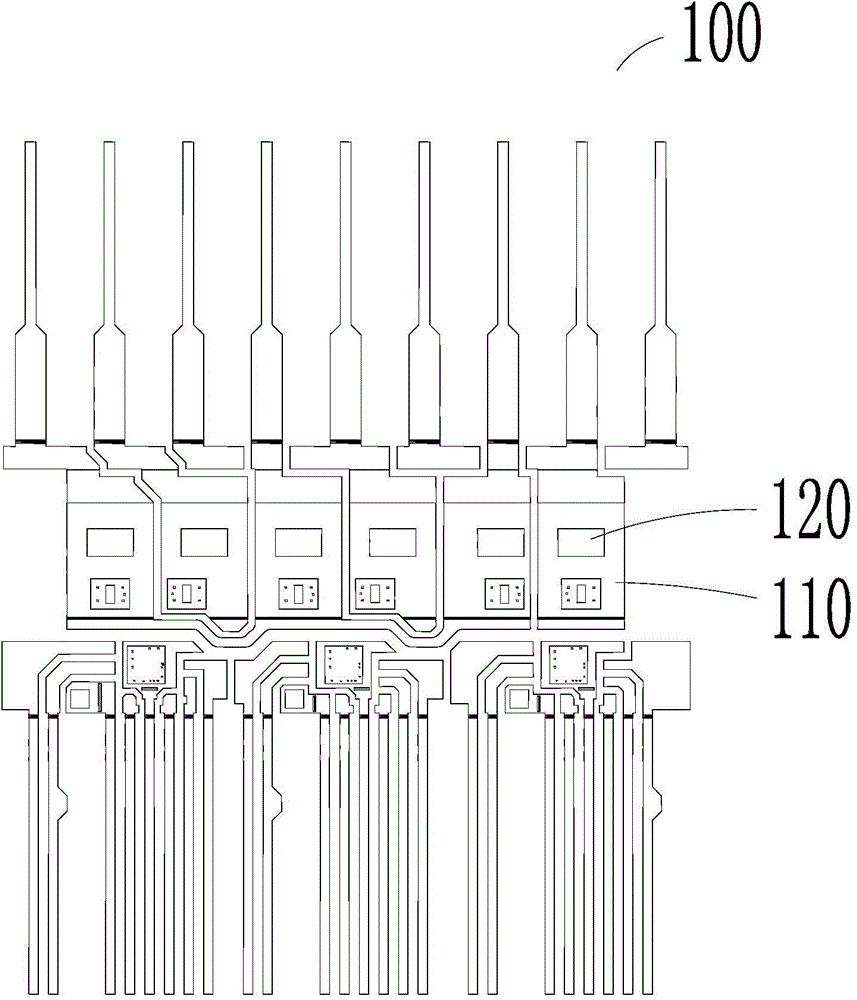

[0022] see figure 1 As shown, it is a schematic cross-sectional view of a frame of a dual in-line package of the present invention. A frame 100 of a dual in-line package of the present invention includes a base island 110 , a chip 120 and inner pins 130 .

[0023] The base island 110 is flat, the inner pins 130 are connected to the base island 110 , and the chip 120 is installed on the base island 110 .

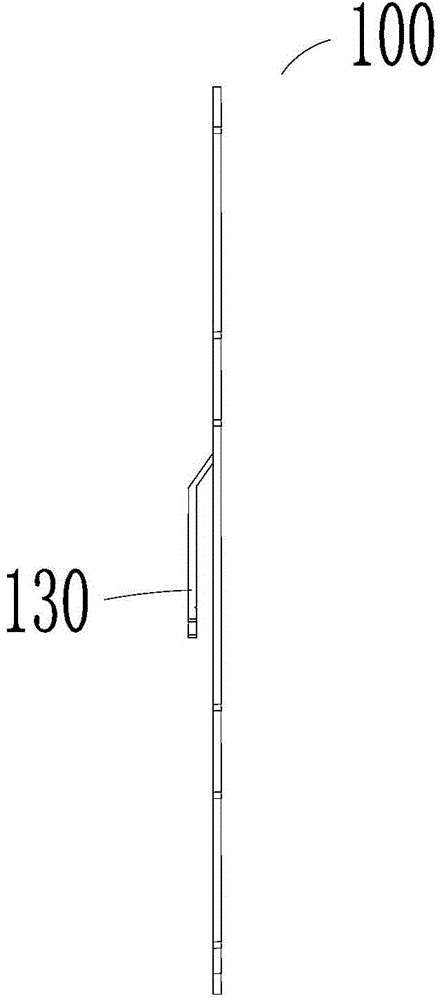

[0024] see figure 2 As shown, it is a schematic left view of the frame of the dual-in-line package of the present invention. There is an angle between the inner pin 130 and the flat surface of the base island 110, and the inner pin 130 forms the angle by bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com