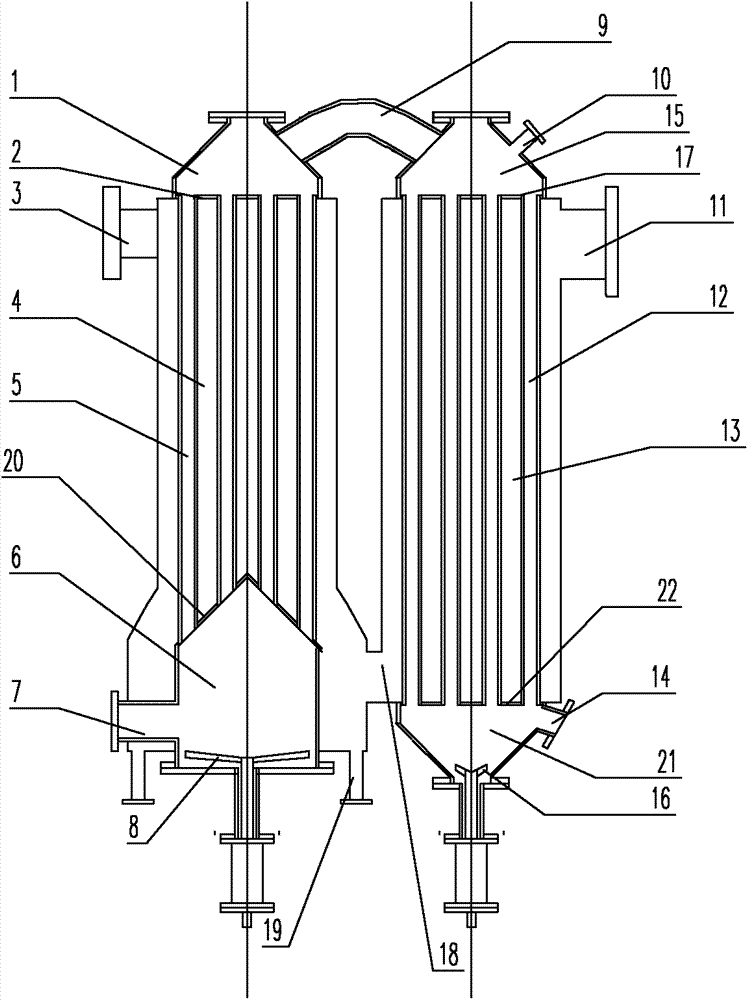

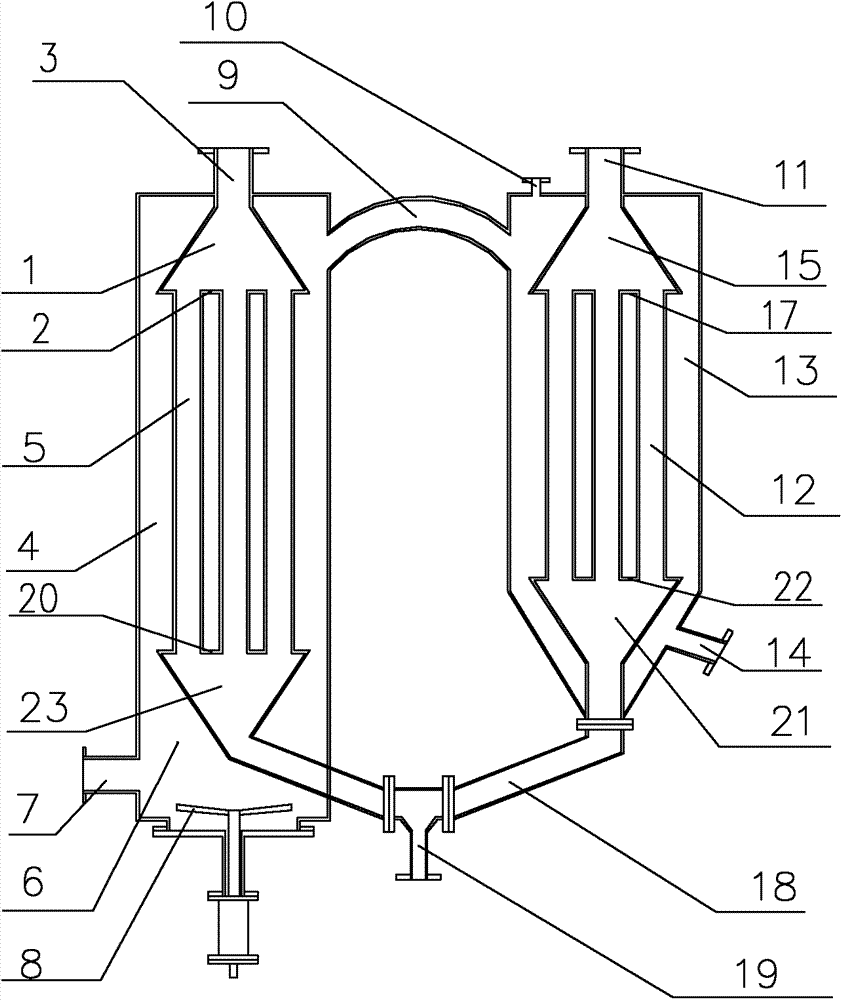

Method and device for air-floatation flow-state high-temperature heat-transfer gasification of biomass

A biomass gas and biomass technology, which is applied in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry, etc., can solve the problems of high heating cost, low gasification efficiency, and long heat transfer distance. Large unit heat transfer area, high tar cracking efficiency, improved uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] The gasification raw material used is pine sawdust, which is processed by a self-made crusher into a particle size of less than 3mm. Using this gasification method, the isolated air is sealed and enters the gas-making furnace. After atomization, it enters the tube layer of the gas-making furnace. The high temperature flue gas with a temperature of 1050°C is passed through the tube shell to crack and gasify the pine wood particles in the tube layer, and the high temperature tar gas and additional water vapor produced enter the carbon coke cracking furnace, where the S / B is 1.02. Tubular heat exchange for cracking and gasification of tar gas, under the heating of high-temperature flue gas at 1400°C, the gasification reaction of tar produces CO and H 2 and CH 4 , the residual carbon also reacts with water vapor to form CO and H 2 .

[0053] The high-temperature flue gas in this experiment is a high-temperature flame produced by the high-temperature combustion of biomass ...

Embodiment 2

[0056]The gasification raw material used is straw, which is crushed to obtain biomass raw materials with a particle size of 3-15mm. Using this gasification method, the air is isolated and sealed into the gas generator, and after atomization, it enters the tube layer of the gas generator , the high-temperature flue gas with a temperature of 900°C is introduced into the tube shell to crack and gasify the straw particles in the tube layer, and the high-temperature tar gas and additional water vapor generated enter the carbon coke cracking furnace, where the S / B is 0.73, The pyrolysis and gasification reaction of tar gas is carried out through tubular heat exchange, and the gasification reaction of tar is generated under the heating of high-temperature flue gas at 1100°C to generate CO and H 2 and CH 4 , the residual carbon also reacts with water vapor to form CO and H 2 .

[0057] The high-temperature flue gas in this experiment is a high-temperature flame produced by the high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com