Denitrated gypsum cleaning device and method

A cleaning and denitration technology, applied in chemical instruments and methods, calcium/strontium/barium compounds, inorganic chemistry, etc., can solve the problems of unachievable solid cleaning effect, improve the efficiency of dehydration and filter cake cleaning, accurate and reliable. regulatory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

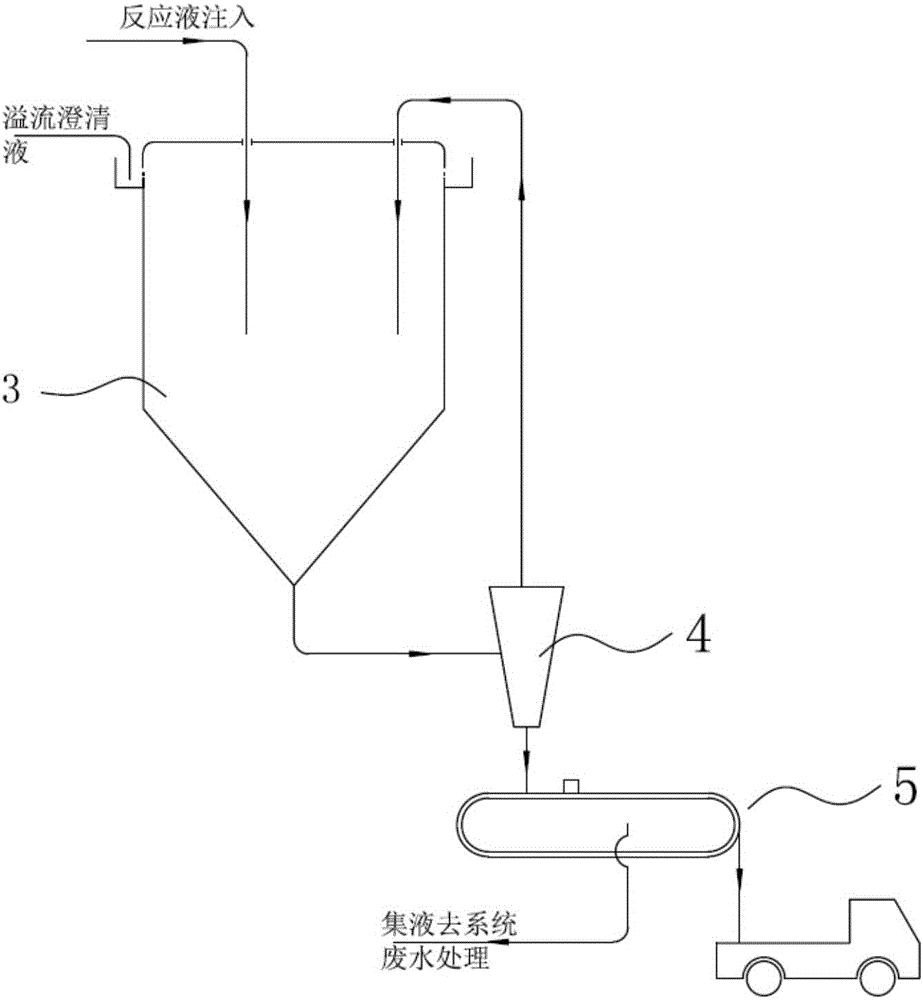

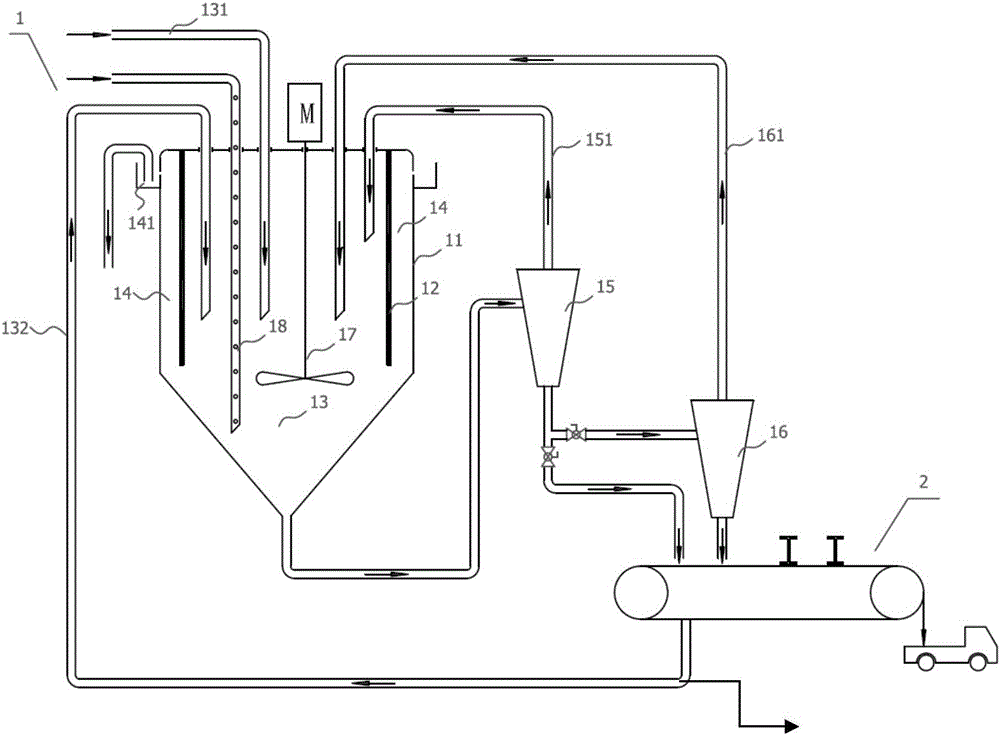

[0032] The purpose of the present invention is to solve the problem of purifying the quality of denitrification gypsum by-product of the alkali plant and removing the salt, so as to meet the use needs of downstream industries, and at the same time ensure that the original brine is not diluted and used for the downstream production of the body to ensure sufficient solid-liquid purpose of separation.

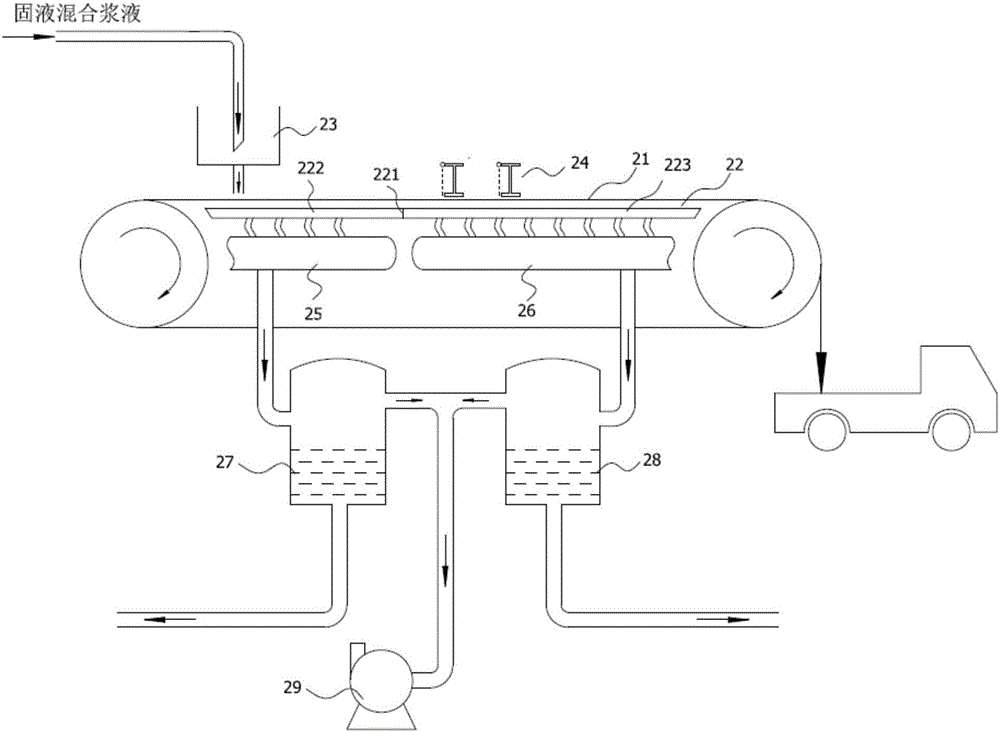

[0033]A core of the present invention is the separation of solid-liquid mixture and slurry, and by adjusting the size of the generated gypsum crystals, the effect of solid-liquid separation is achieved. There are special requirements for the filtrate, and at the same time, the separated solids are cleaned and desalinated Devices and processes designed and invented for processing.

[0034] The usual vacuum belt dehydrator only focuses on the dehydration effect, the humidity of the dehydrated solids, etc., but does not pay attention to the filtrate after dehydration. On the basis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com