Liquid methanol heating furnace

A heating stove and methanol technology, which is applied to liquid heating fuels, hot water stoves/stoves, household stoves/stoves, etc., can solve the problems of wasting energy and time, inconvenient to use, etc., and achieves short heat transfer distance, flexible operation, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

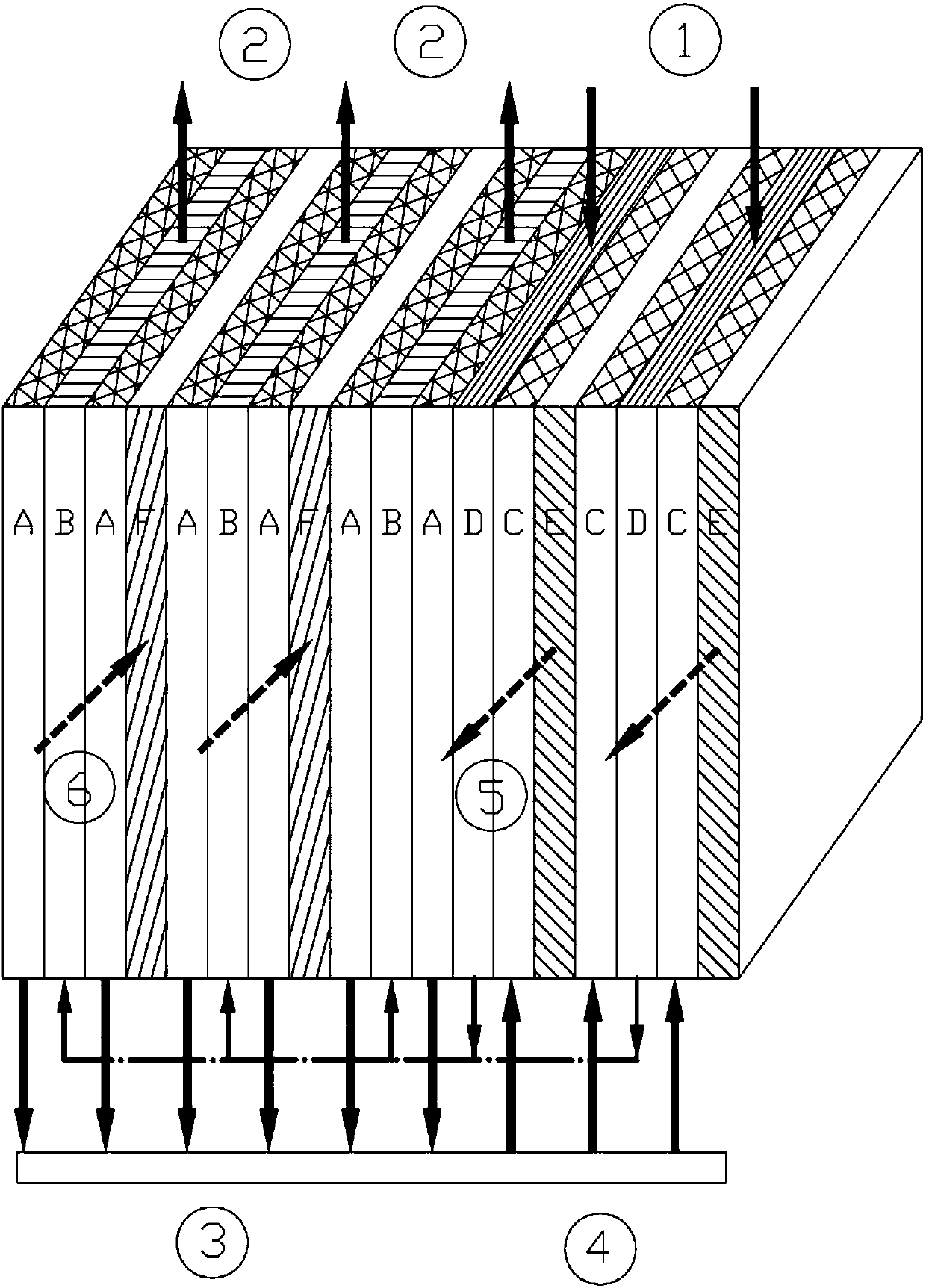

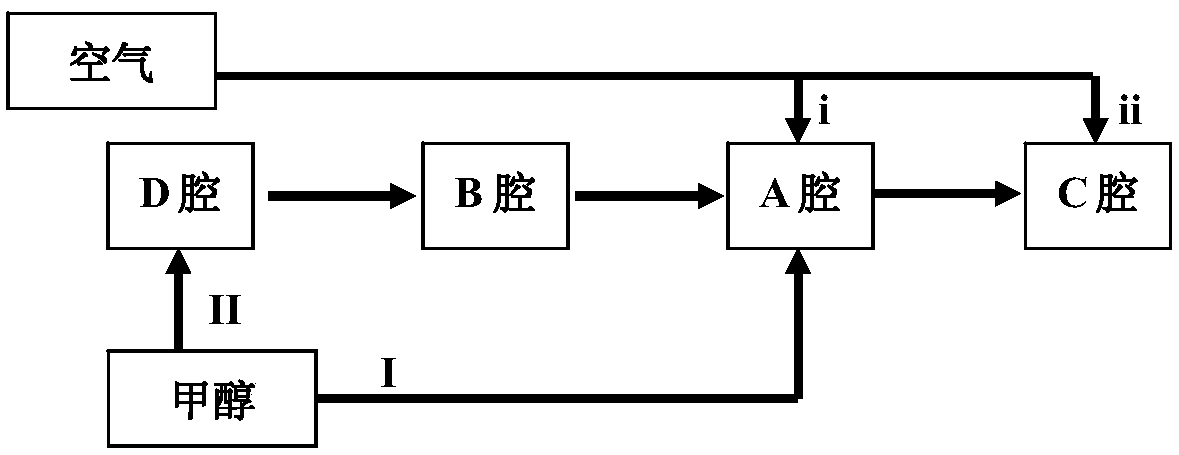

[0040] A liquid methanol heating stove, such as figure 1As shown, the liquid methanol heating furnace is a device that integrates liquid methanol low-temperature start-up, methanol vaporization, methanol catalytic combustion and water preheating, including a methanol primary combustion chamber (A), a methanol vaporization chamber (B), and a methanol secondary combustion chamber. chamber (C), methanol preheating chamber (D), water heating chamber (E), and water preheating chamber (F); by adopting the method of catalytic combustion of liquid methanol, the low-temperature start-up of methanol is realized, and the failure caused by electric heating is avoided. Disadvantages such as high power consumption and insufficient compact structure of the system; the use of two methanol combustion chambers avoids the disadvantages of traditional methanol heating furnaces that use open flame combustion, low heat utilization rate, and insufficient combustion. Methanol catalytic combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com