Non-wear laminated solid-liquid separation device

A solid-liquid separation, lamination technology, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problem of wear of moving filter and screw shaft, etc., to prolong the service life, reduce the pitch, and achieve the effect of treatment Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

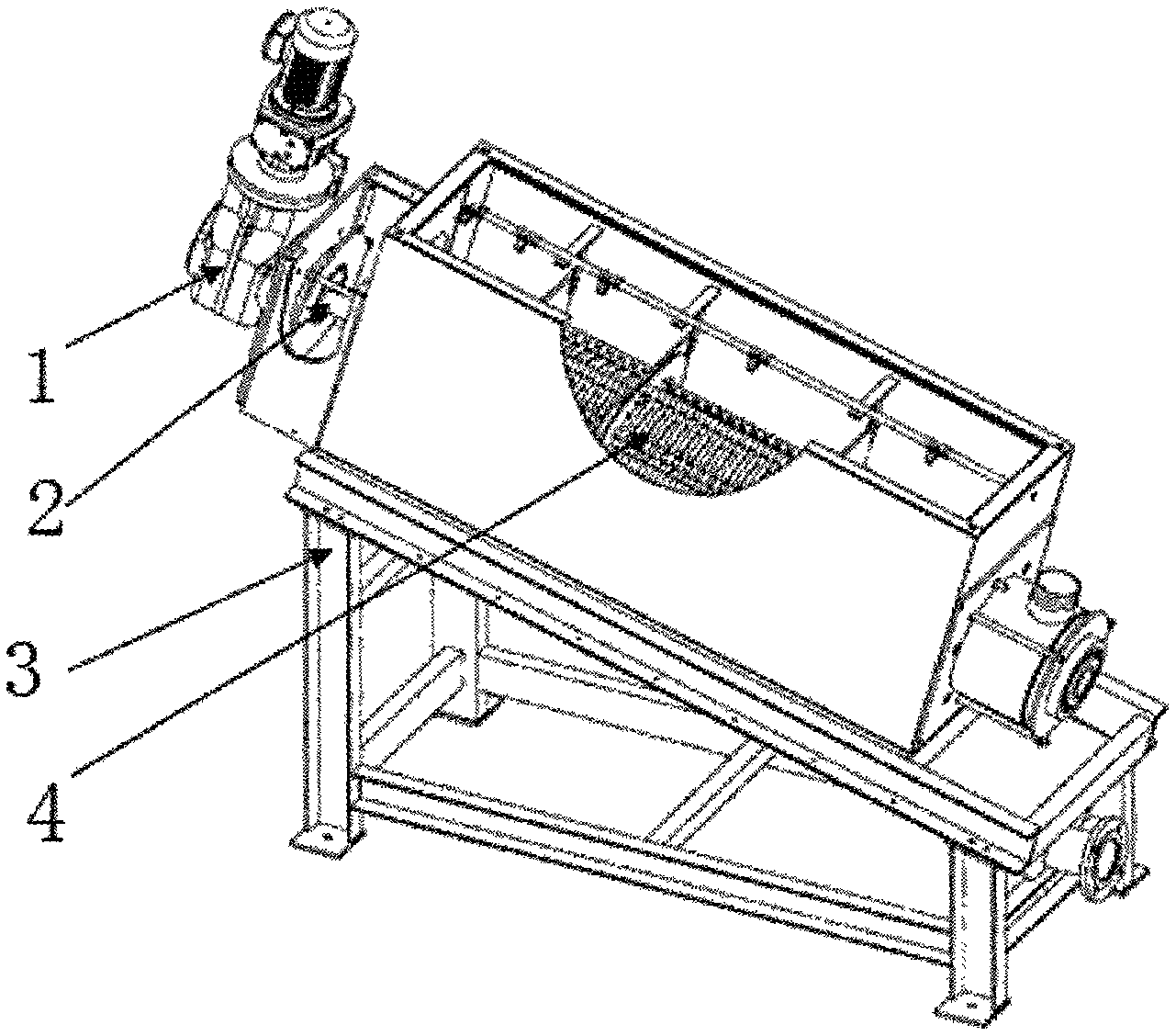

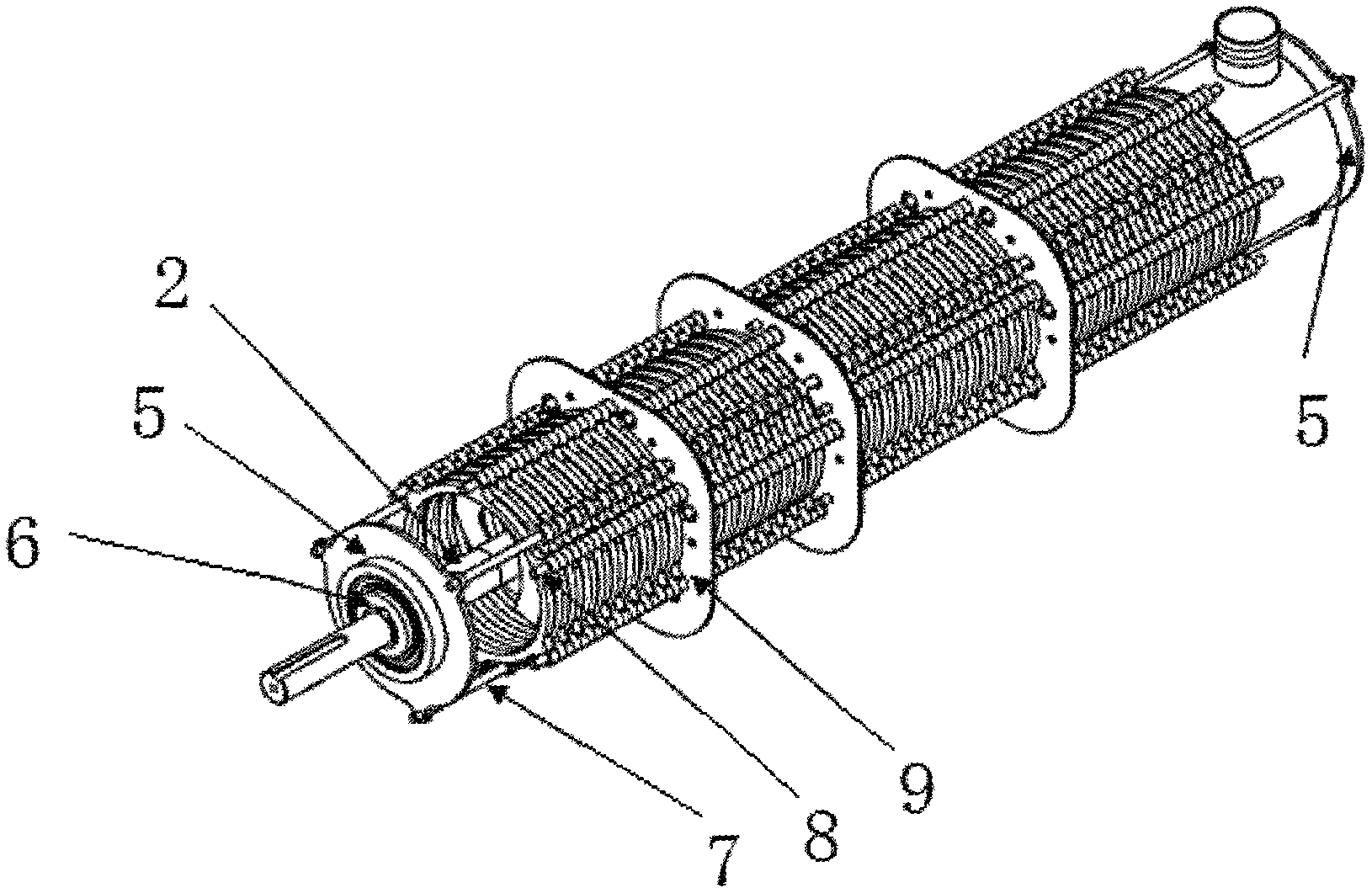

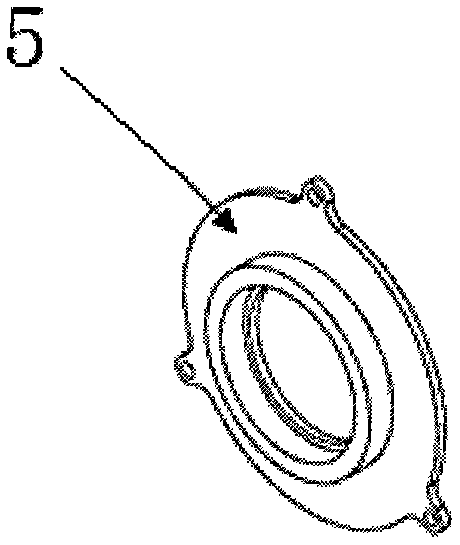

[0024] Such as Figure 1 ~ Figure 6 As shown, the wear-free laminated solid-liquid separation device includes a base 3, a screw shaft with spiral blades 2, a reduction motor 1 that drives the screw shaft to rotate, and a filter pack 4 nested around the screw shaft. The filter group 4 is composed of a number of fixed plates 10 and moving plates 11 arranged at intervals in the axial direction, and a fixed plate support shaft 8, a fixed plate support plate 9, and a moving plate support shaft 7, which are connected to support them. 4Fixed on the base 3 by the stator support plate 9. There are 6 ears around each stator 10, and each ear is provided with a positioning hole for the stator support shaft 8 to pass through, and all the stators 10 pass through. The stator support shaft 8 that penetrates them is connected to the stator support plate 9. Each of the moving plates 11 has 3 ears around it, and each ear has a positioning hole for the moving plate support shaft 7 to pass through....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com