Air purification equipment and air purification device comprising air purification equipment

An air purification equipment and air technology, which is applied in the field of air purification equipment and air purification devices, can solve the problems of low adsorption efficiency of charged particles, low single filtration efficiency, small contact surface area, etc., to increase the probability of capture, Improves the chance of adsorption and increases the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment is further deepened on the structural basis of the above-mentioned air purification equipment. It is known that each set of conductive material parts comprises two layers of conductive material with a dust collecting plate between the two layers of conductive material. Preferably, a dust collecting plate is provided between each group of conductive material parts.

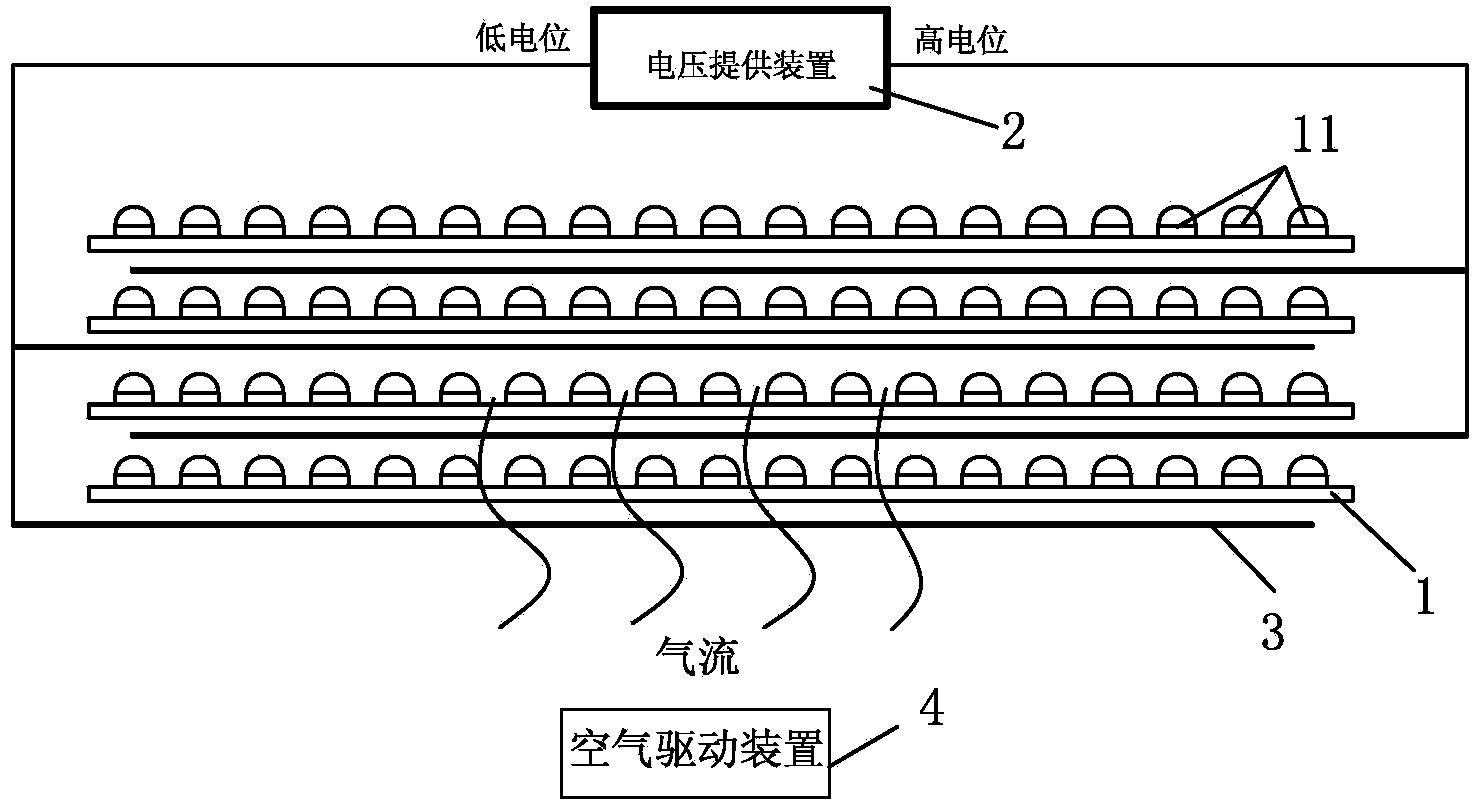

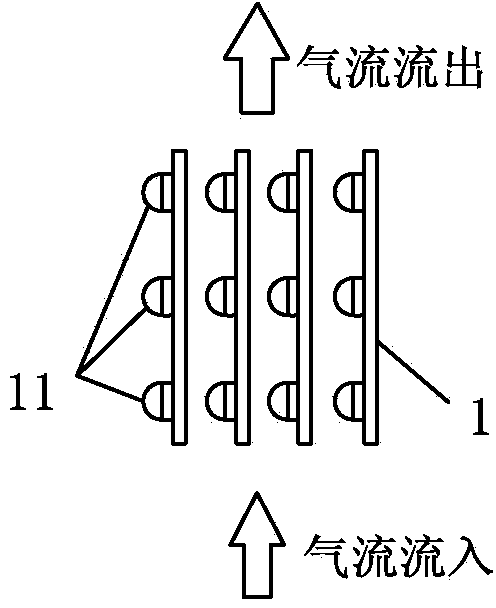

[0041] Such as Figure 4 As shown, the layers of conductive material and the dust collecting plate 1 are alternately arranged. The polarity between adjacent layers of conductive material of a dust collection plate is reversed. When the material of the dust collecting plate contains electret material, a semi-permanent electret electric field is formed inside under the action of an external electric field. When the voltage supply device 2 is turned on, a uniform electric field is formed between adjacent conductive material layers, and at the same time, the electric field polarizes the electr...

Embodiment 2

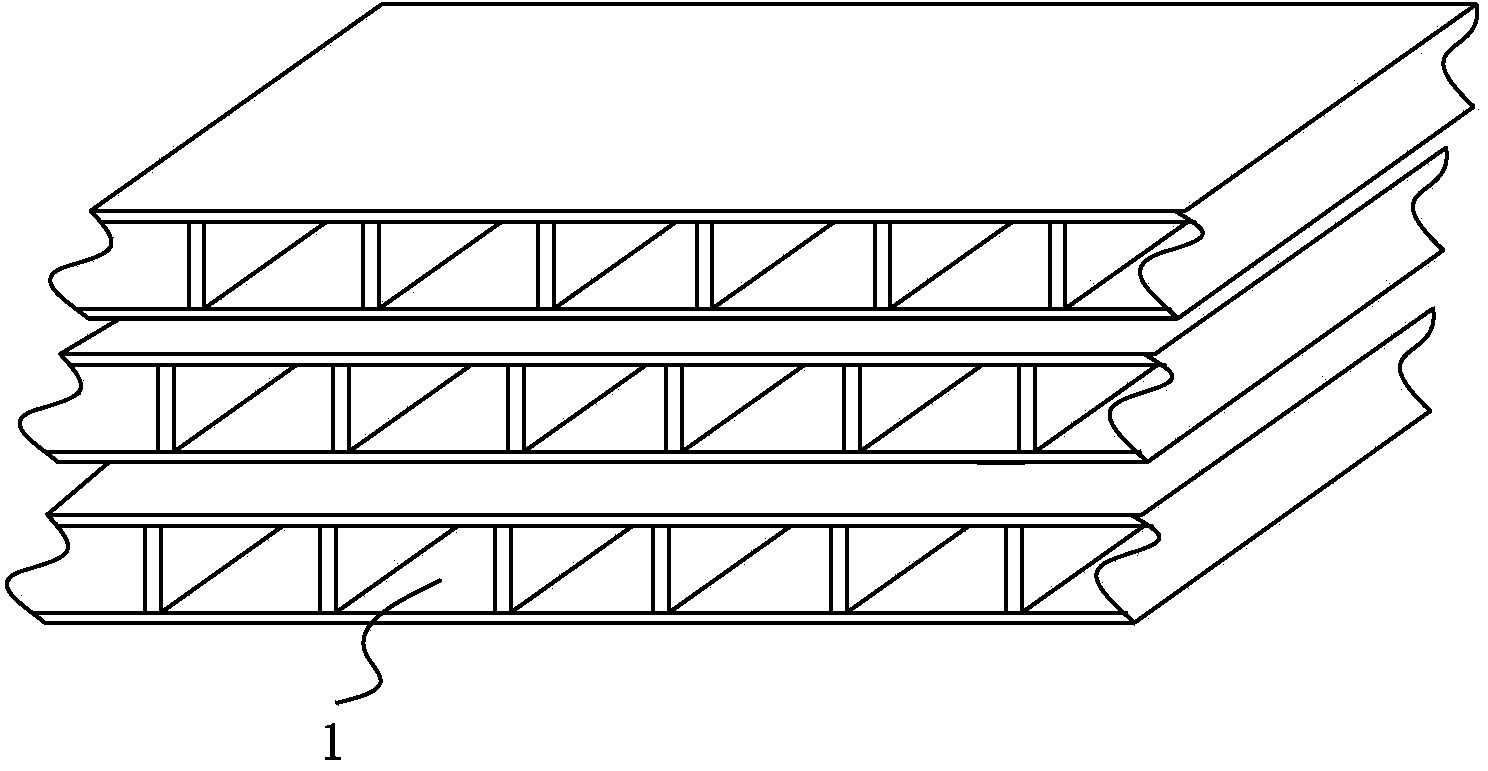

[0045] The difference between this embodiment and the first embodiment lies in that at least two dust collecting plates are arranged between each group of conductive material parts. The material of the dust collecting plate contains electret material, and a semi-permanent electret electric field is formed inside under the action of an external electric field. A plurality of dust-collecting plates 1 are stacked together to form a filter device, and the overall dust-collecting area is greatly increased through multiple sets of stacked arrays of dust-collecting plates. Due to the existence of the electret, there is no particularly large loss of efficiency if the dust collecting plates are arranged at intervals of one sheet or at intervals of multiple sheets. In the experiment, the difference in purification efficiency loss between three electrodes and one electrode at intervals is about 5%. This solution can reduce the cost of implementation by reducing the number of electrode d...

Embodiment 3

[0047] This embodiment is improved on the basis of Embodiment 1 or Embodiment 2. Such as Figure 4 As shown, there is an air gap 5 between the conductive material layer and the dust collecting plate in this embodiment, that is, there is no contact between the conductive material layer and the dust collecting plate. The air gap between the conductive material layer and the dust collecting plate is realized by the bracket 6 . The bracket 5 is arranged between the two dust-collecting plates 1, and the conductive material layer and the dust-collecting plates are overhead, so that an air gap 5 is formed between the two brackets and the dust-collecting plates. Figure 4 The support is "H" type, two support legs support its two dust collecting plates 1, and the upper and lower surfaces of the connecting plate in the middle are respectively provided with a conductive material layer, and the two conductive material layers are conducted. Or just a layer of conductive material. Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com