The Method of Product Classification in the Production of PVC Paste Resin

A technology for polyvinyl chloride paste and resin is applied in the field of product classification in the production of polyvinyl chloride paste resin, which can solve problems such as single product, and achieve the effects of less equipment, reduced power consumption and high classification accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

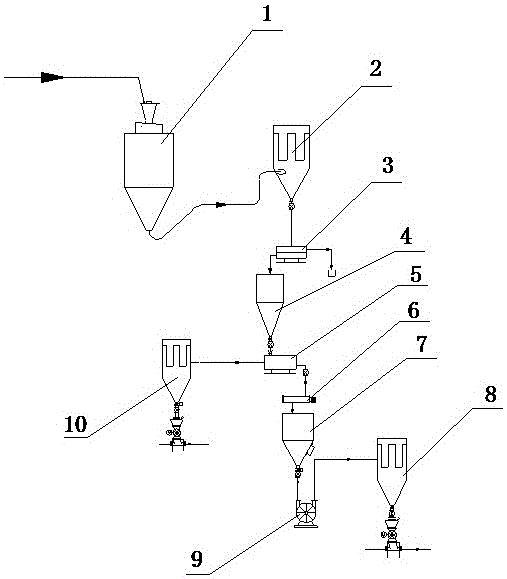

[0016] Refer to attached figure 1 , a polyvinyl chloride paste resin product classification device, including a spray drying tower 1, a first-stage bag filter 2, a vibrating screen 3, a powder collection tank 4, a classifier 5, a second-stage bag filter A 10, and a screw conveyor connected in sequence 6, two-stage powder collection tank 7, pulverizer 9, two-stage bag filter B 8; the latex from the latex receiving tank enters the high-speed centrifugal spray drying tower to dry the latex, remove the moisture in the latex, and obtain dry resin powder; The dried resin powder enters a section of bag filter for gas-solid separation, and the resin powder is collected at the bottom of a section of bag filter; the resin collected at the bottom of a section of bag filter passes through a vibrating screen to separate the coarse particles, and then collects the coarse particles from the side , bagged; the resin powder from the vibrating screen enters the powder collection tank, and is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com