Straight welded joint crack sensitivity evaluation method and multivariant restraining plate for evaluating

A technology of crack sensitivity and evaluation method, which is applied in the field of cold crack sensitivity evaluation of pipeline steel plate and pipe welding, can solve the problem of cold crack sensitivity of crack sensitive welding that has not yet been found, and achieve the effect of enhancing the restraint effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

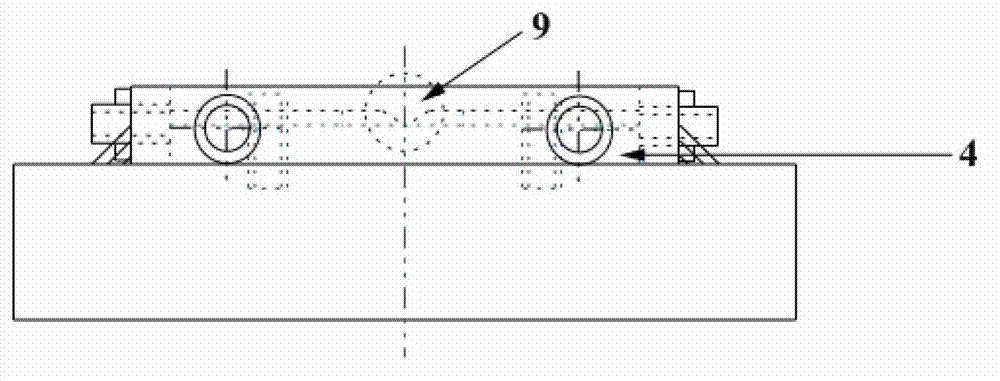

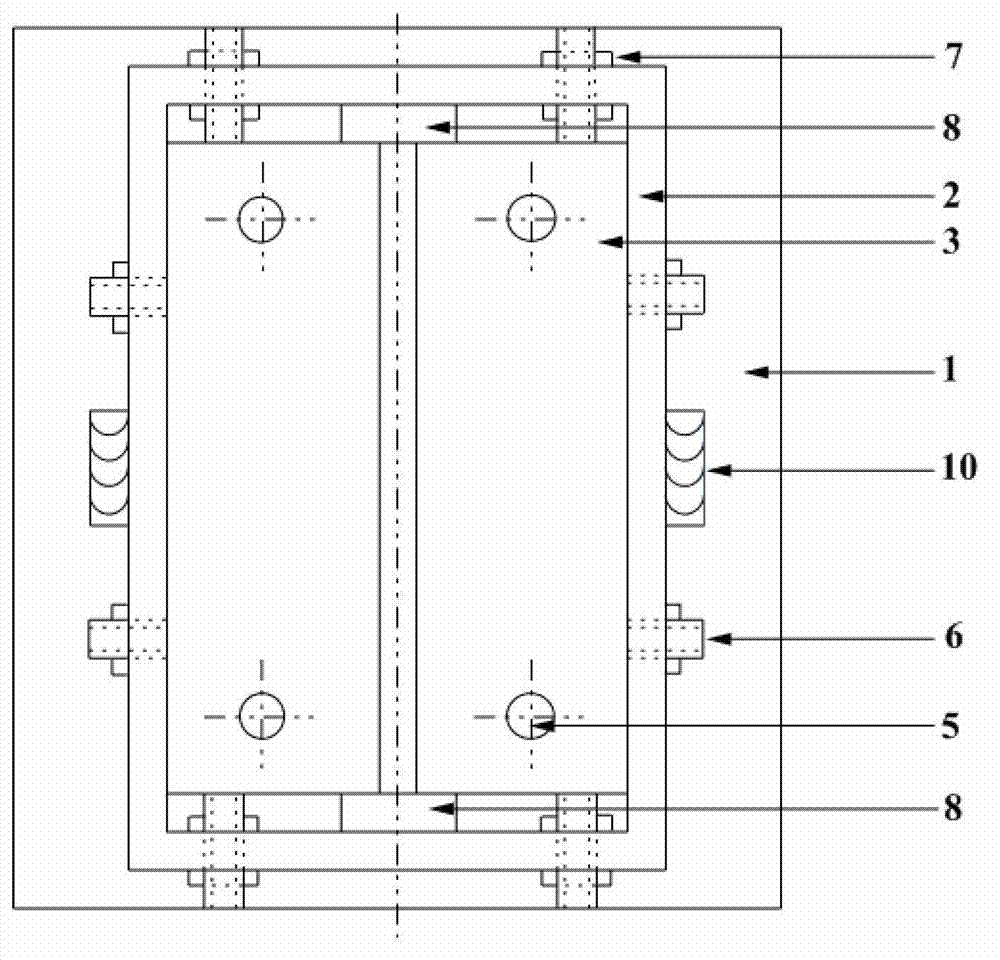

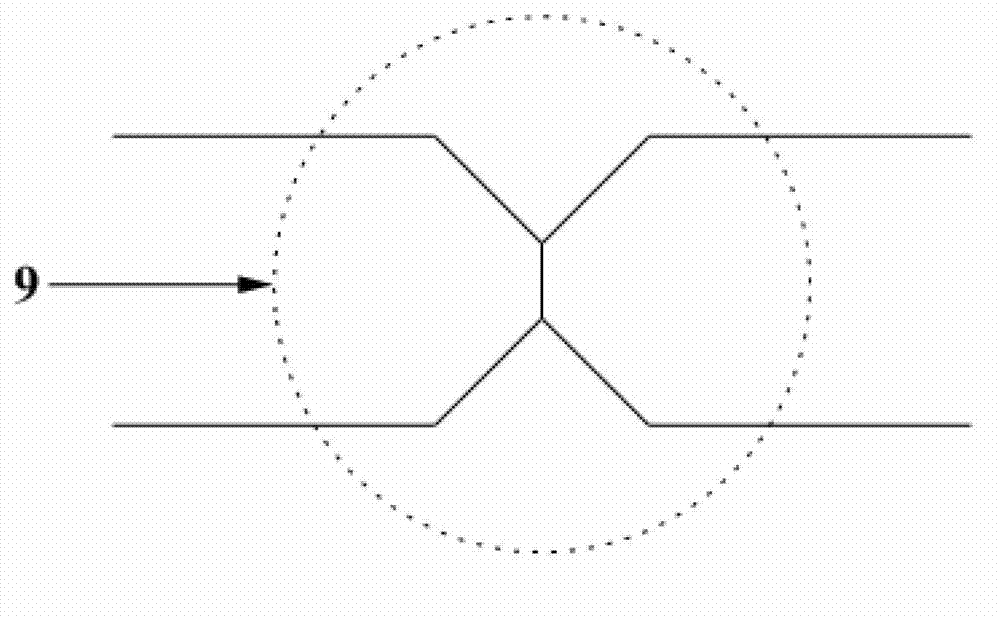

[0086] Figure 1 and figure 2 shown.

[0087] Large-caliber longitudinal submerged arc welding pipe welding mainly includes high-speed melting electrode gas shielded pre-welding and double-sided inner and outer multi-wire submerged arc welding. When it is necessary to evaluate the crack sensitivity in the pre-welding process of pipeline steel plate pipe, apply the same welding process as that of on-site pipe making, and carry out a melting electrode gas shielded welding on the multi-component restraint plate of the present invention. After welding is completed 24 hours The pipeline steel plate 3 to be evaluated is removed from the multi-component restraint plate, and the welding crack sensitivity under the condition of on-site pipe pre-welding is evaluated by means of ultrasonic non-destructive testing and macroscopic and microscopic crack inspection.

[0088]When it is necessary to evaluate the crack sensitivity in the internal and external submerged arc welding process of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com