Automatic feeding and discharging device applied to numerically-controlled machine tool

A technology of automatic loading and unloading and CNC machine tools, applied in the direction of automatic in/out of workpieces, metal processing machine parts, metal processing, etc., can solve the problems of not greatly improving efficiency, increasing enterprise procurement costs, and high labor costs to achieve efficiency Improve and reduce the effect of idle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

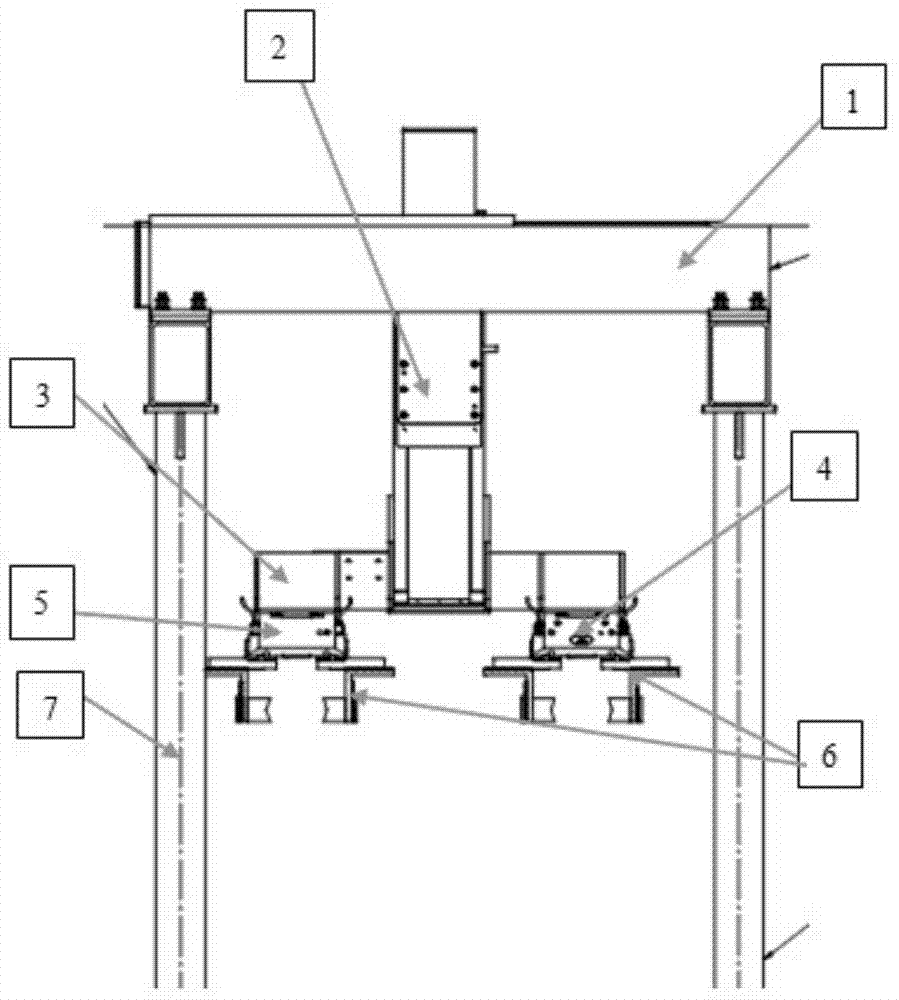

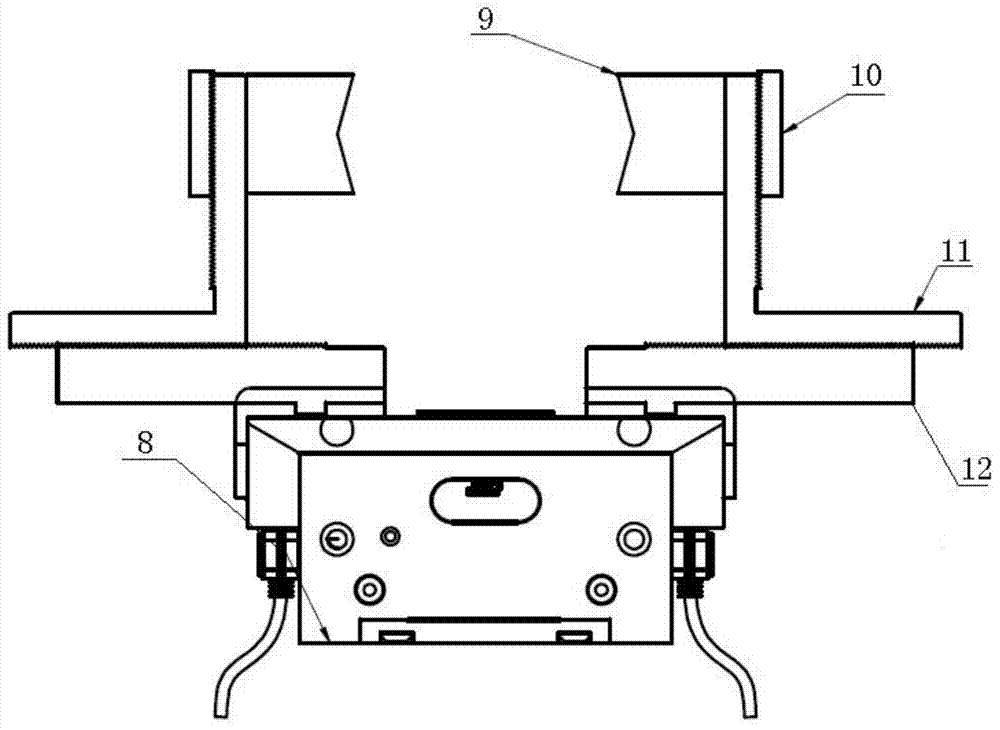

[0009] Such as Figure 1-2 A schematic diagram of the structure of the present invention is given. An automatic loading and unloading device used on a CNC machine tool, which has a door frame 7, and is characterized in that the door frame 7 is equipped with a horizontal module 1 that moves vertically on the door frame 7, and a vertical module that moves left and right is installed on the horizontal module 1. Module 2, the two sets of modules are cross-composed and driven by a servo motor. The horizontal module 1 is equipped with a loading hand grip 4 and a feeding hand grip 5 through a connecting lever 3, and the loading hand grip 4 and the unloading hand grip 5 Grabbing fingers 6 are all equipped on the hands 5, and the gripping fingers 6 are controlled by the gripper control assembly 8 to clamp and loosen the workpiece. The grasping finger 6 has a pair of thumbs 12, the thumb 12 is a rack structure and moves under the control of the gripper control assembly 8, the thumb 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com