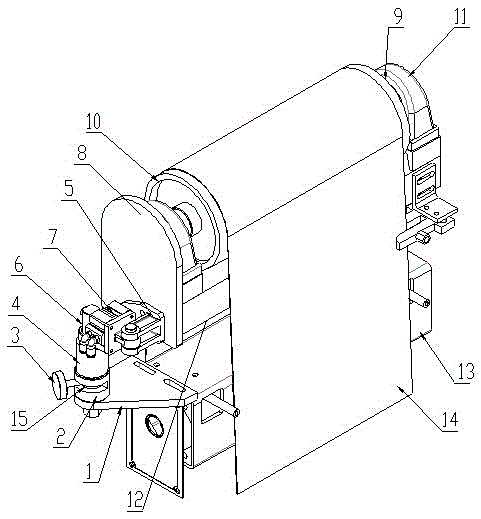

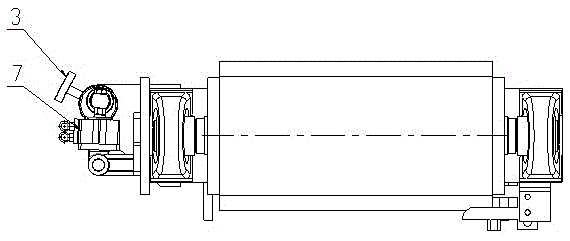

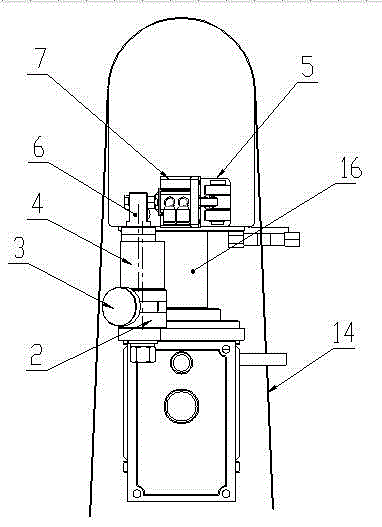

Front cam type abrasive belt rectification mechanism and rectification method of broadband sander

A wide-band sander, cam-type technology, applied in belt grinders, feeding devices, automatic control devices, etc., can solve problems such as deviation, inconvenience, and insecurity, and achieve time-saving and labor-saving operation, easy maintenance, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, a method for correcting the deviation of the front cam type abrasive belt of a broadband sander, when it is necessary to adjust the angle between the tension roller and the headstock (contact roller), loosen the lock Screw 3 and turn the locking screw 3, the locking screw 3 flexibly moves in the chute 15 and drives the eccentric shaft sleeve 4 in the column sleeve 2 to rotate, the eccentric shaft sleeve 4 drives the telescopic column 6 to perform cam eccentric movement, and at the same time the telescopic column 6 drives the swing head cylinder 7 to drive the upper beam 12 through the upper beam connection seat 8 to make a slight angular deviation, and then tighten the locking screw 3 after deflecting to a suitable position, the operation is very convenient and fast.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com