Linear precast slipform construction device

A technology for construction devices and prefabricated parts, applied to supply devices, manufacturing tools, ceramic molding machines, etc., can solve problems such as high trimming and transportation costs, high slip-form trimming rate, and inability to produce column-beam-strip-shaped concrete members. , to achieve the effect of no freight expenses, good product quality, safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

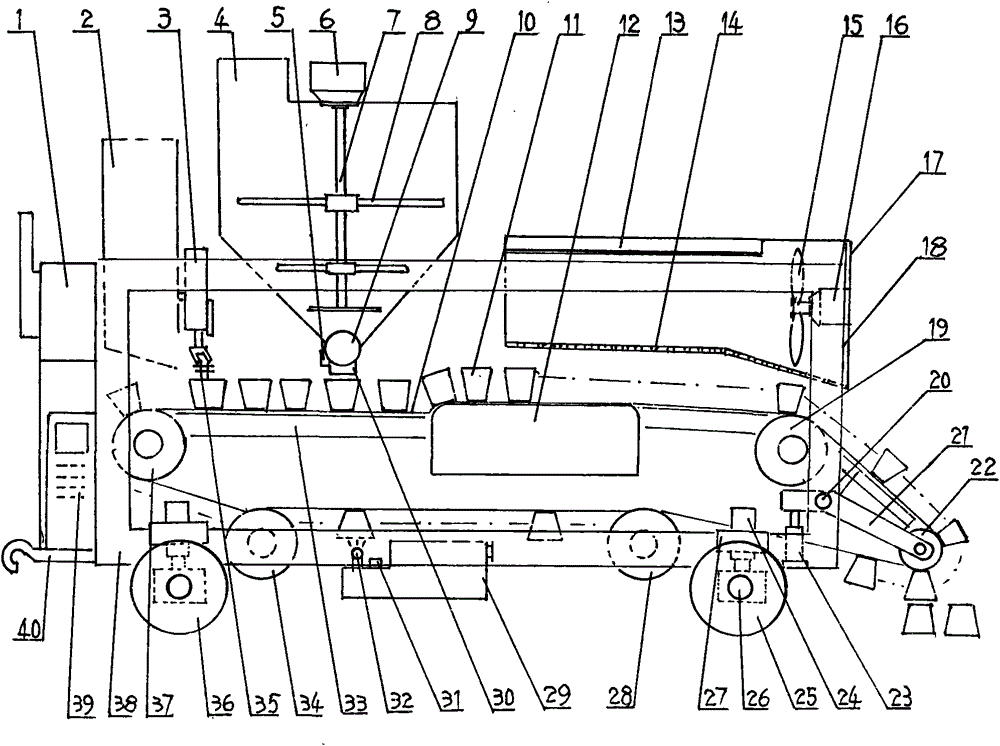

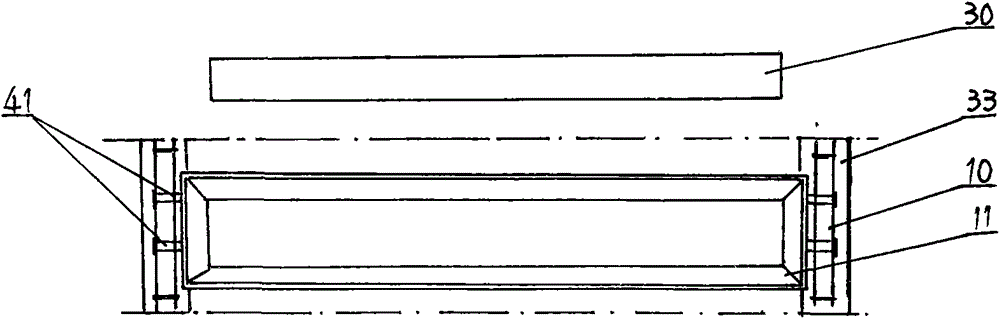

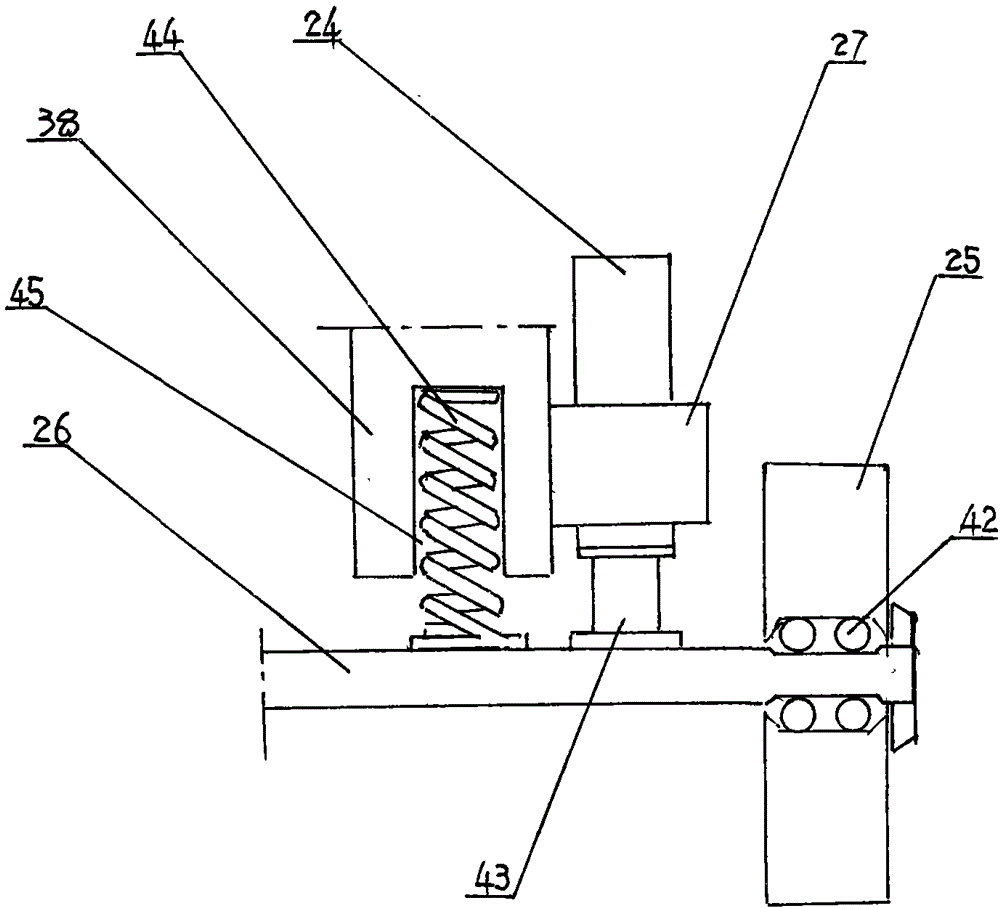

[0024] Such as Figure 1 to Figure 4 Shown, a kind of linear prefabricated part slip form construction device is made up of engine 1, operation control box 39, car body 38, front wheel 36 and rear wheel 25. The upper part of the car body is provided with a steel bar rack device, a storage device and a drying device in sequence from front to back. The rear lower end of the device continues to the rear lower end of the vehicle body. in:

[0025] The engine provides the required power for the various operating devices of the car body, and the engine is located at the front of the car body or on the tractor. The engine can be an engine powered by oil, or an electric motor. The engine can drive the generator to provide power for each running device of the car body.

[0026] The mold box running device is used to make each mold box 11 pass through the steel bar frame device, the storage and discharge device, the drying device and the vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com