Latex glove preparation method

A technology of latex gloves and gloves, applied in the direction of coating, can solve the problem of high production cost of natural rubber gloves, achieve good physical and chemical properties, and reduce the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

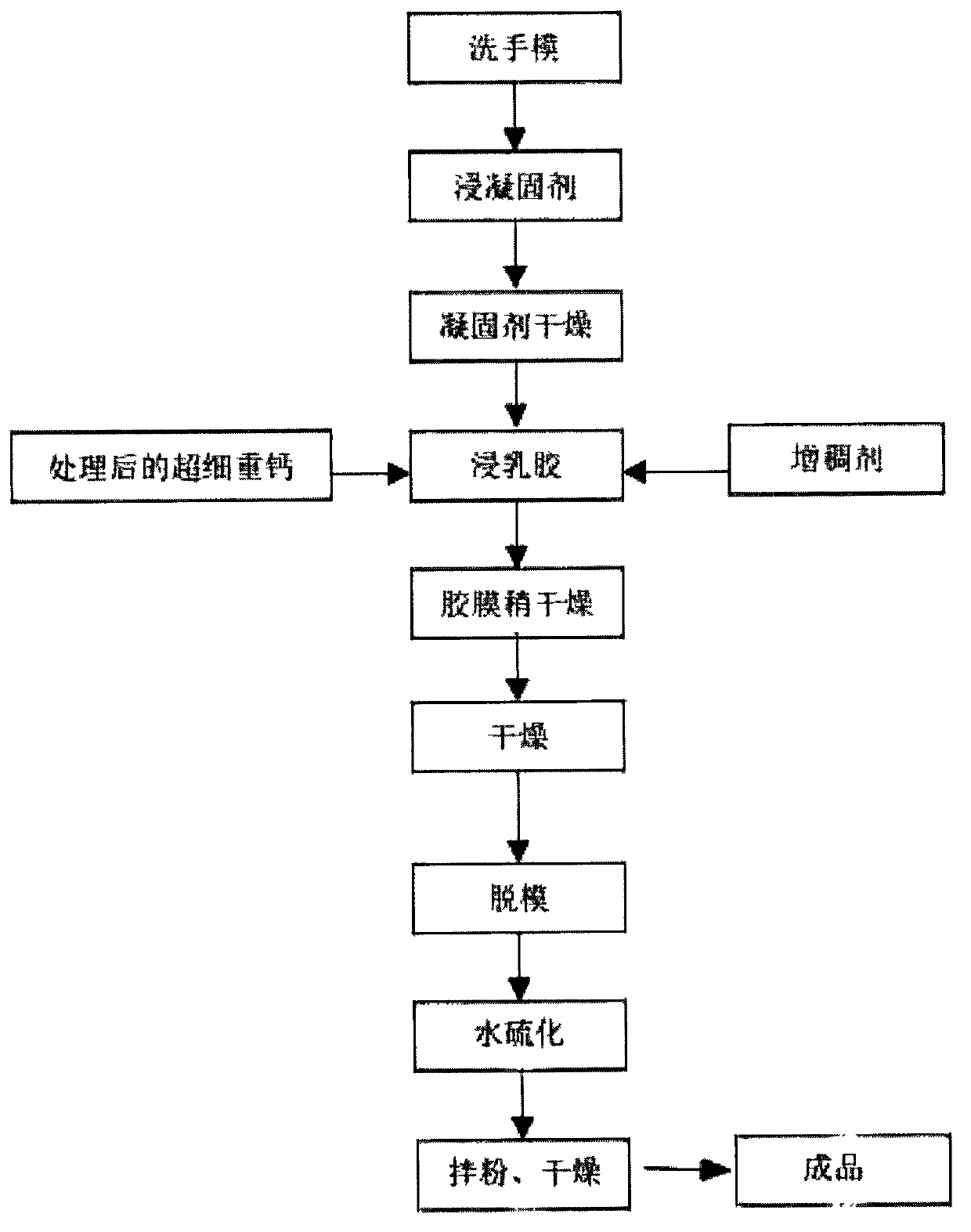

Image

Examples

Embodiment 1

[0021] Hand-washing mold: dip and pickle the glove mold with hydrochloric acid for 10 seconds, rinse it with water, and then rinse it with hot water at 80°C; soak the coagulant: dip the cleaned mold into the coagulant at 60°C, and the soaking time 1 minute; coagulant drying: After the glove mold is impregnated with the coagulant, it is dried at 120°C for 3 minutes; dipping in latex: the aforementioned dried glove mold is dipped into latex, which contains superfine heavy calcium and thickener solution, the dipping temperature is 45°C, and the dipping time is 2 minutes; the film is slightly dry: after the glove mold is dipped in latex, dry it at 120°C for 3 minutes; demoulding: use clean water to clean the latex gloves on the glove mold Rinse and demold; water vulcanization: put the latex gloves that have been demolded into a mixing tank and soak them in 95°C water for 60 minutes; powder mixing: stir the latex gloves after water vulcanization in talcum powder for 30 minutes, take...

Embodiment 2

[0023] Hand-washing mold: dip and pickle the glove mold with hydrochloric acid for 15 seconds, rinse it with clean water, and then rinse it with hot water at 85°C; soak the coagulant: dip the cleaned mold into the coagulant at 60°C, the soaking time 1 minute; coagulant drying: After the glove mold is impregnated with the coagulant, it is dried at 120°C for 3 minutes; dipping in latex: the aforementioned dried glove mold is dipped into latex, which contains superfine heavy calcium and thickener solution, the dipping temperature is 45°C, and the dipping time is 2 minutes; the film is slightly dry: after the glove mold is dipped in latex, dry it at 120°C for 3 minutes; demoulding: use clean water to clean the latex gloves on the glove mold Rinse and demold; water vulcanization: put the latex gloves that have been demolded into a mixing tank and soak them in 95°C water for 60 minutes; powder mixing: stir the latex gloves after water vulcanization in talcum powder for 30 minutes, ta...

Embodiment 3

[0025] Hand-washing mold: dip and pickle the glove mold with hydrochloric acid for 15 seconds, rinse it with clean water, and then rinse it with hot water at 85°C; soak the coagulant: dip the cleaned mold into the coagulant at 60°C, the soaking time 1 minute; coagulant drying: After the glove mold is impregnated with the coagulant, it is dried at 120°C for 3 minutes; dipping in latex: the aforementioned dried glove mold is dipped into latex, which contains superfine heavy calcium and thickener solution, the dipping temperature is 45°C, and the dipping time is 2 minutes; the film is slightly dry: after the glove mold is dipped in latex, dry it at 120°C for 3 minutes; demoulding: use clean water to clean the latex gloves on the glove mold Rinse and demold; water vulcanization: put the latex gloves that have been demolded into a mixing tank and soak them in 95°C water for 60 minutes; powder mixing: stir the latex gloves after water vulcanization in talcum powder for 30 minutes, ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com