Upward flow combined type secondary biological film sewage treatment integrated equipment

A sewage treatment, combined technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of large footprint, achieve small footprint and long service life Long-term, fast start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

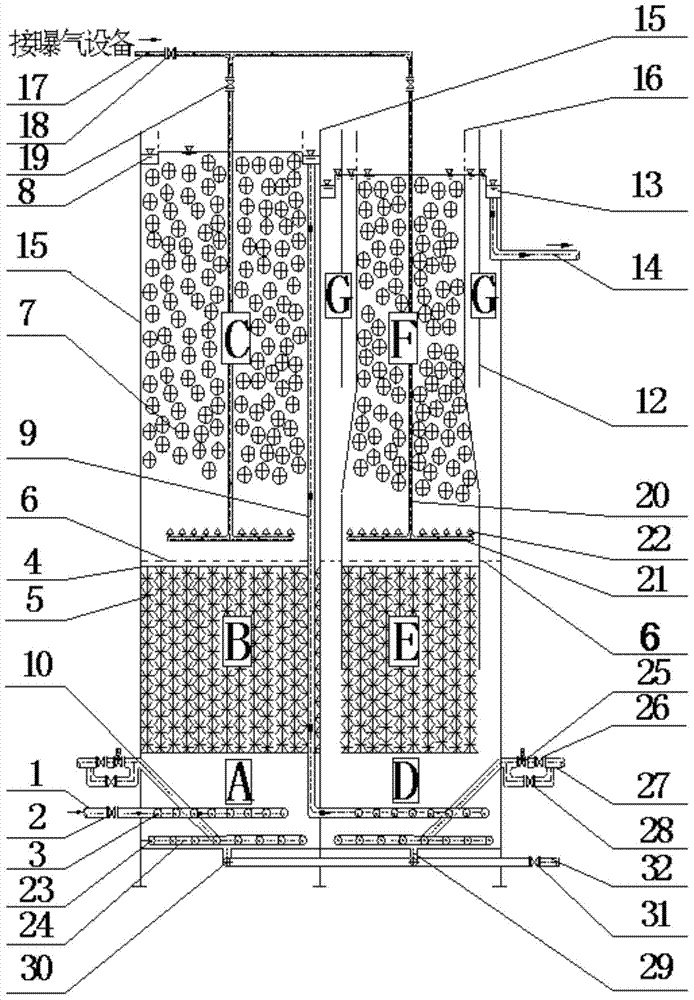

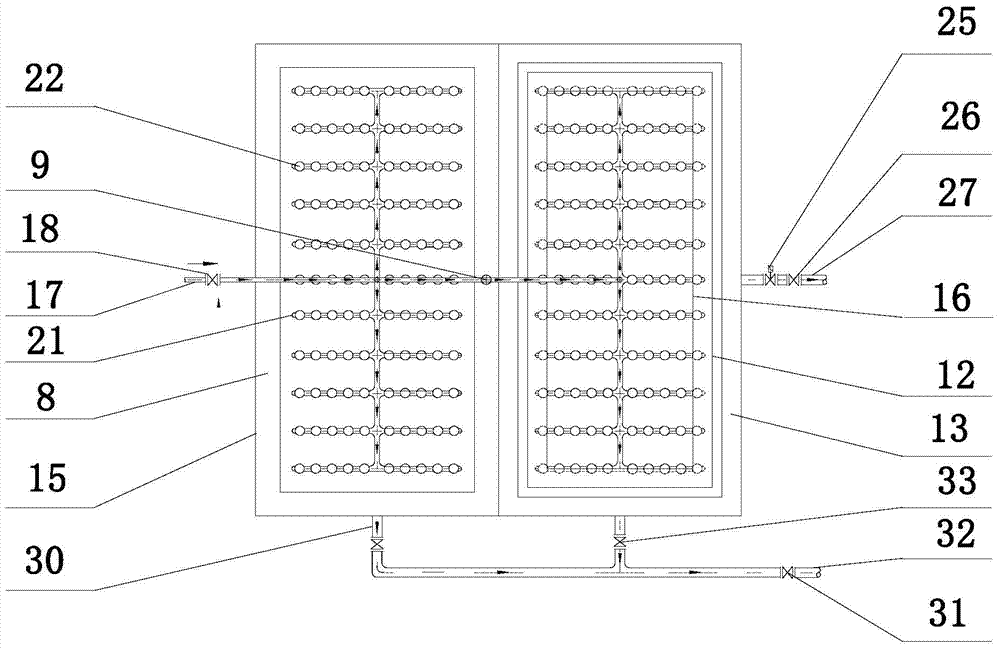

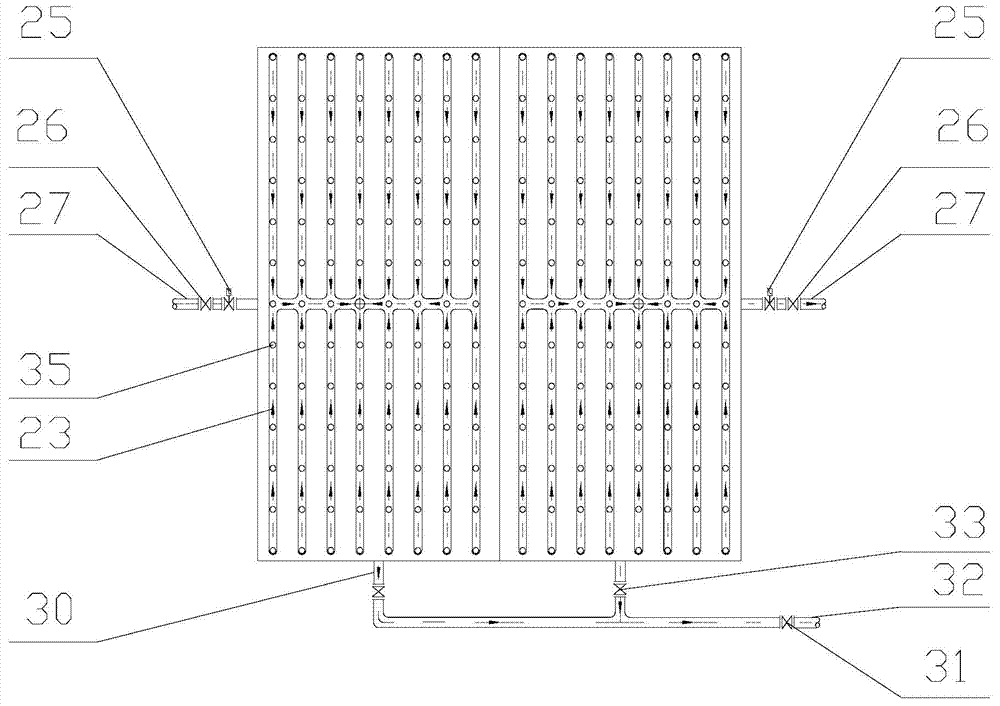

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The upflow combined secondary biofilm sewage treatment integrated equipment includes a shell and seven treatment areas inside the shell. The seven treatment areas in the shell are separated by horizontal partitions 6, vertical partitions I15 and vertical partitions II16 constitute. The horizontal partition 6 is located at the middle and lower positions in the housing, and divides the housing into upper and lower parts. Holes are evenly distributed on the horizontal dividing plate 6, which is a perforated dividing plate, and the aperture of the hole on the horizontal dividing plate 6 is not greater than the particle size of the mobile packing 7 in the mobile packing area. The vertical partition I15 is located at the center of a pair of sides of the housing. From the upper end of the housing to above the bottom of the housing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com