Rare earth europium (III) organic complex light-emitting material and preparation method thereof

A technology of organic complexes and luminescent materials, applied in the field of synthesis of new rare earth luminescent materials, can solve the problems of inferior crystal quality of phosphors, difficult to control particle shape, low luminous efficiency, etc., and achieve easy separation and purification, simple device, fine and uniform particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

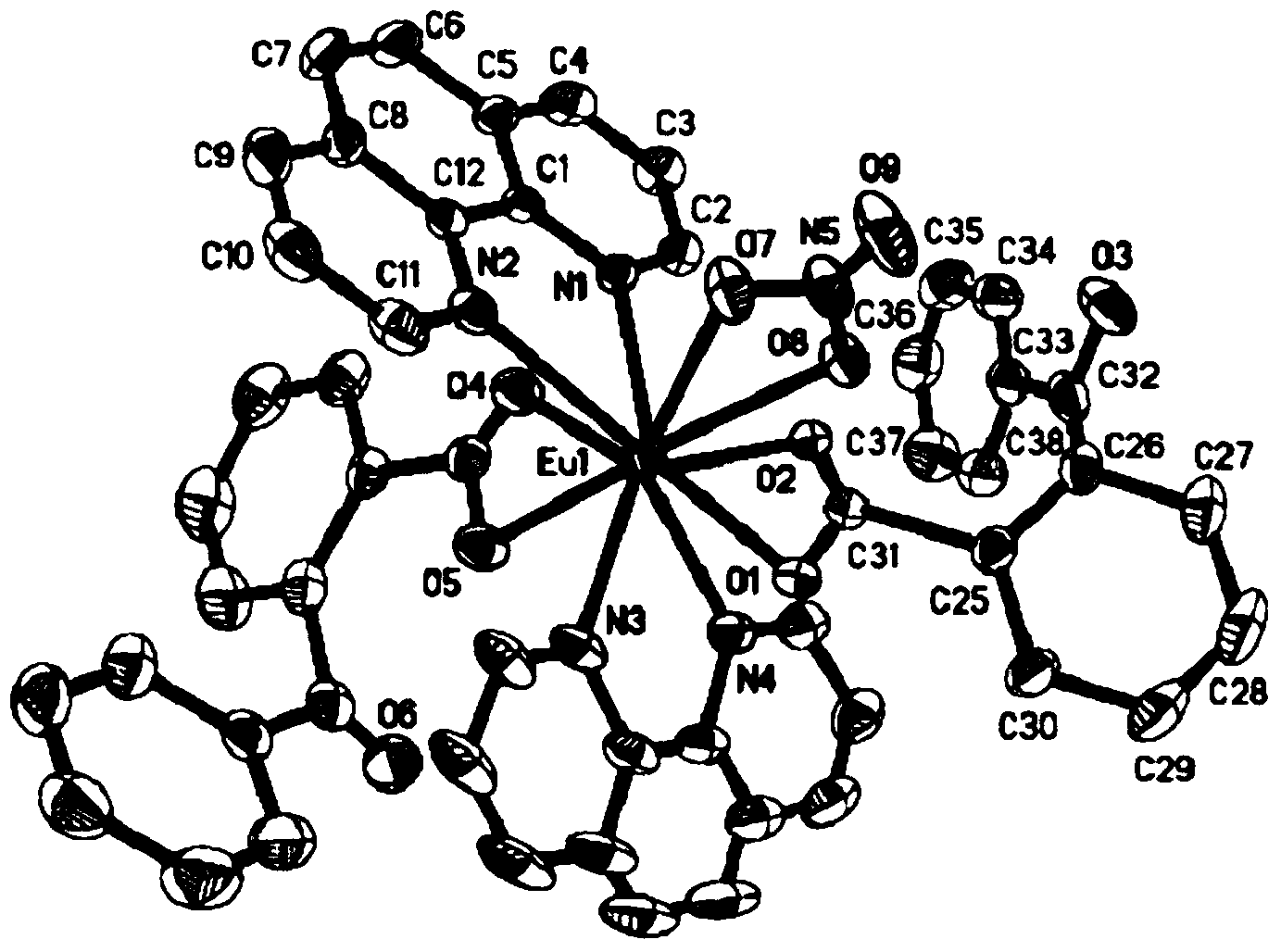

[0030] Eu(C 14 h 9 o 3 ) 2 (Phen) 2 (NO 3 ) Synthesis of materials:

[0031] Add 0.47mmol (0.106g) of 2-benzoylbenzoic acid, 0.43mmol (0.086g) of 1.10-phenanthroline and 0.21mmol (0.093g) of europium nitrate hexahydrate into a 100mL round-bottomed flask, and use 7mL of A mixed solvent (2:5 by volume) composed of water and N,N'-dimethylformamide was dissolved, and 0.05 mL of a sodium hydroxide solution with a concentration of 1 mol / L was added to the mixed solution. Install a reflux condenser, heat in a water bath with a magnetic constant temperature water bath, control the temperature at 50°C, and react with constant temperature stirring for 8 hours. After the solution is cooled, filter it, cover the filtrate with a layer of microporous fresh-keeping film, place it at room temperature to volatilize naturally, and obtain a colorless crystal product after five weeks. The yield is about 43.1%.

Embodiment 2

[0033] Eu(C 14 h 9 o 3 ) 2 (Phen) 2 (NO 3 ) Synthesis of materials:

[0034]Add 0.40mmol (0.090g) of 2-benzoylbenzoic acid, 0.40mmol (0.080g) of 1.10-phenanthroline and 0.20mmol (0.088g) of europium nitrate hexahydrate into a 100mL round-bottomed flask, and use 8mL of A mixed solvent (volume ratio of 3:5) composed of water and N,N'-dimethylformamide was dissolved, and 0.05 mL of a sodium hydroxide solution with a concentration of 0.8 mol / L was added to the mixed solution. Install a reflux condenser, heat with a magnetic constant temperature water bath, control the temperature at 45°C, and stir at a constant temperature for 9 hours. After the reaction is completed, wait for the solution to cool, filter, and cover a layer of perforated plastic wrap on the mouth of the beaker containing the filtrate. , placed at room temperature to volatilize naturally, and a colorless transparent crystal was obtained after five weeks with a yield of 41%.

Embodiment 3

[0036] Eu(C 14 h 9 o 3 ) 2 (Phen) 2 (NO 3 ) Synthesis of materials:

[0037] Add 0.40mmol (0.090g) of 2-benzoylbenzoic acid, 0.40mmol (0.080g) of 1.10-phenanthroline and 0.18mmol (0.080g) of europium nitrate hexahydrate into a 100mL round-bottomed flask, and use 6mL from A mixed solvent (1:5 by volume) composed of water and N,N'-dimethylformamide was dissolved, and 0.04 mL of a sodium hydroxide solution with a concentration of 1.2 mol / L was added to the mixed solution. Install a reflux condenser, heat with a magnetic constant temperature water bath, control the temperature at 55°C, and stir at a constant temperature for 7 hours. After the reaction is completed, wait for the solution to cool, filter, and cover the mouth of the beaker containing the filtrate with a layer of microporous fresh-keeping The thin film was placed at room temperature to volatilize naturally, and colorless transparent crystals were obtained after five weeks with a yield of 39%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap