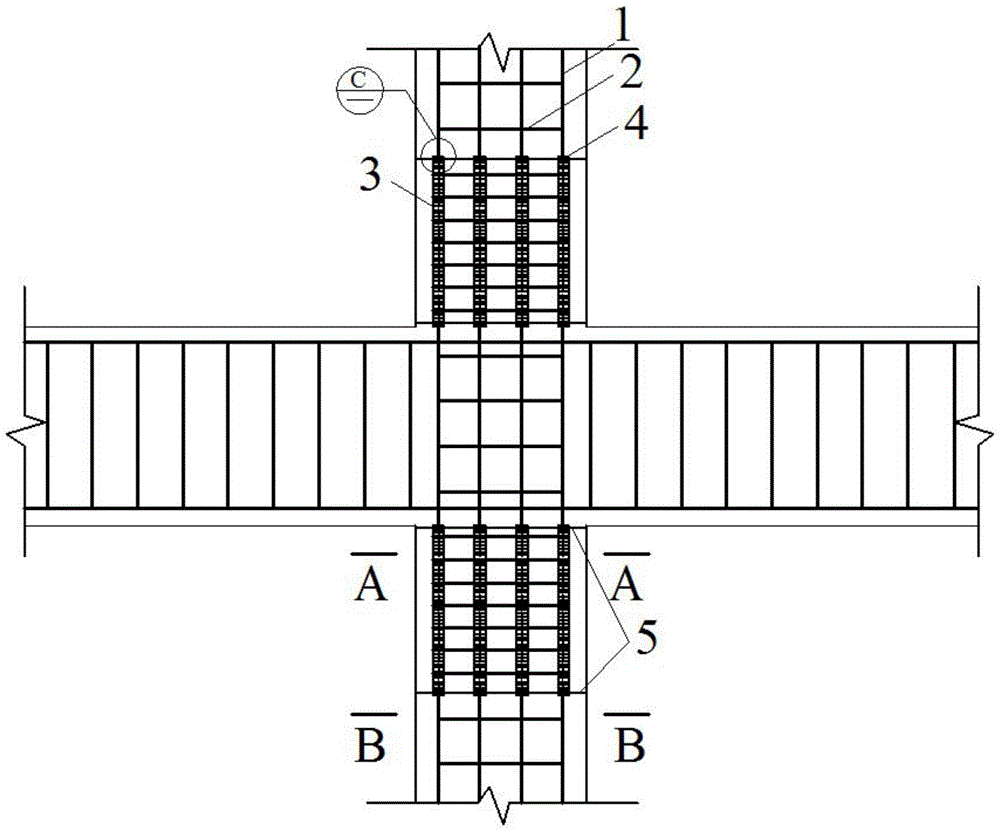

End unbonded reinforced concrete column and preparation method

A reinforced concrete column, non-bonded technology, applied in the field of reinforced concrete columns, can solve the problems of reduced bearing capacity, poor energy dissipation capacity, etc., to achieve the effects of enhanced energy dissipation capacity, improved energy dissipation capacity and ductility, and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

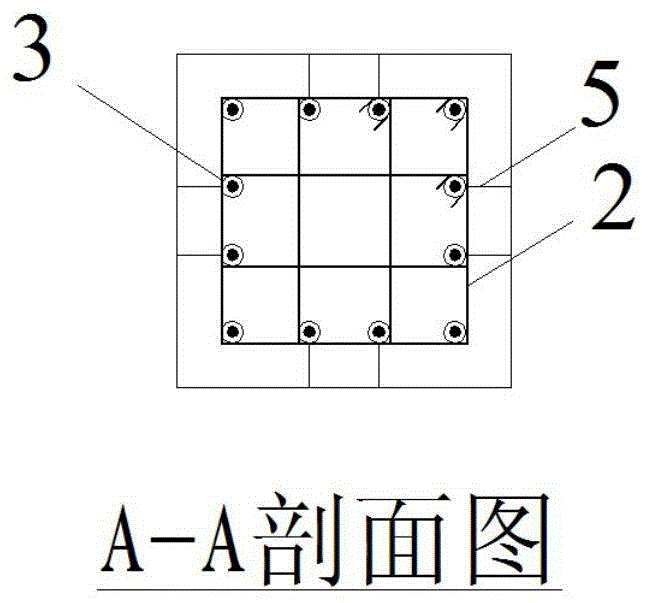

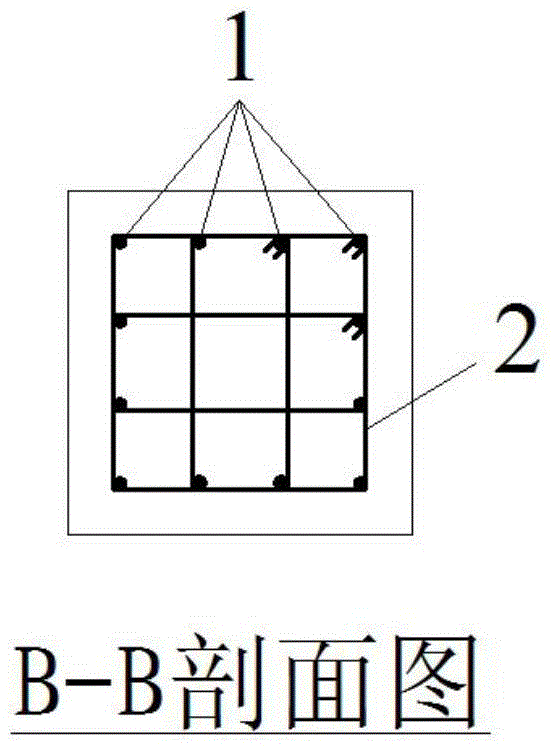

Method used

Image

Examples

Embodiment Construction

[0029] The following description is only one of the embodiments of the present invention, and it can also be used for some steel bars in the plastic hinge area of other column members. Any modifications, changes or equivalent transformations made to the above examples according to the technical essence of the present invention shall belong to the protection scope of the technical solution of the present invention.

[0030] 1. Production of related materials

[0031] Select the diameter as the diameter of the longitudinal bar d 1 1.5 times the steel belt bellows, cut to 1 times the height H of the column section, and each set of unbonded steel bars at the end is equipped with two sections of steel belt bellows. The thickness of the foam circular gasket is 3cm, and it is cut into a circular gasket with the inner diameter of the bellows as the diameter, and the diameter d is at the center of the circle. 1 For perforation, each steel bellows needs two corresponding foam round ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com