Sliding arc ignition device

An ignition device and sliding arc technology, which is applied in the direction of rocket engine devices, jet propulsion devices, gas turbine devices, etc., can solve problems that have not yet reached mature application, achieve the effects of enhanced combustion, reduced ignition delay time, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

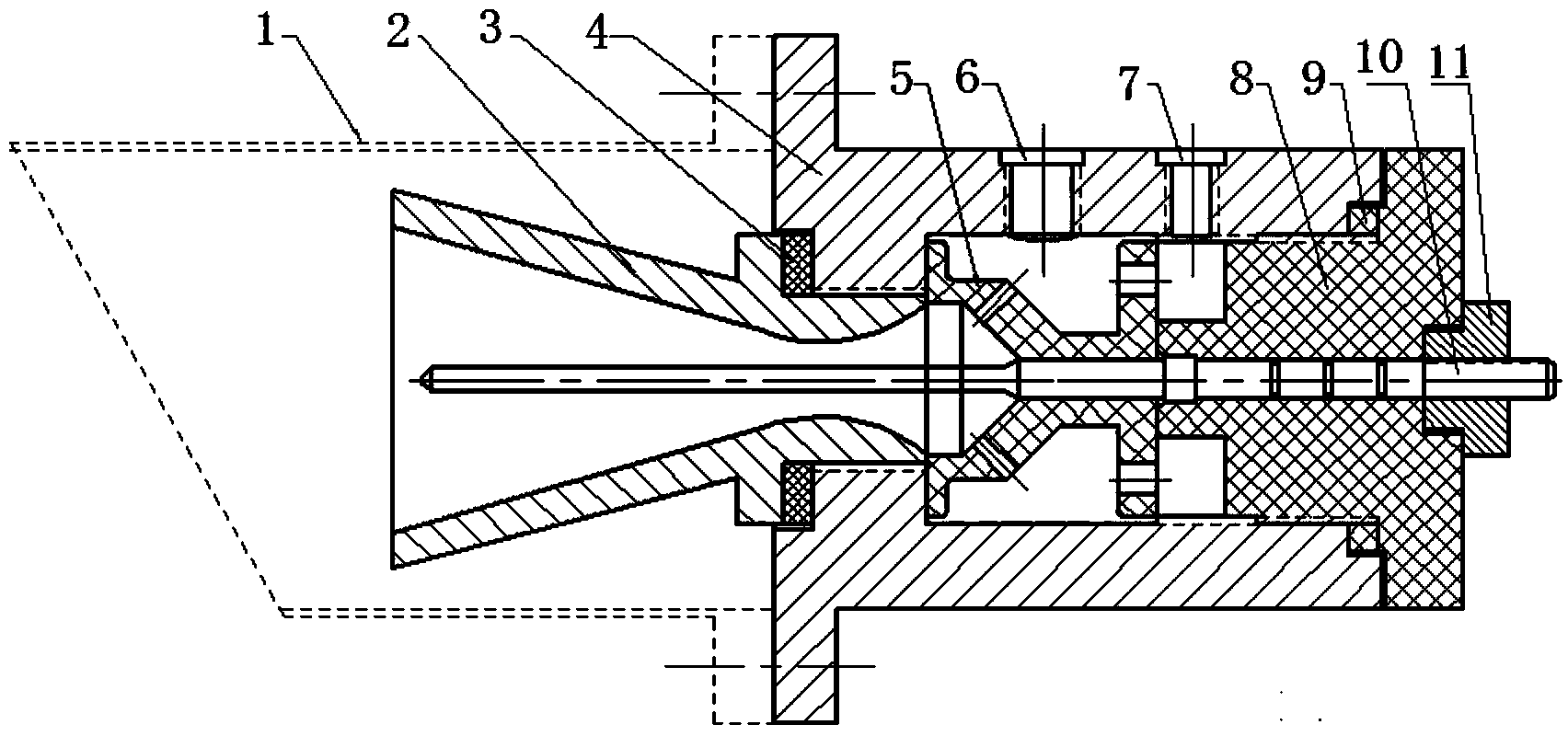

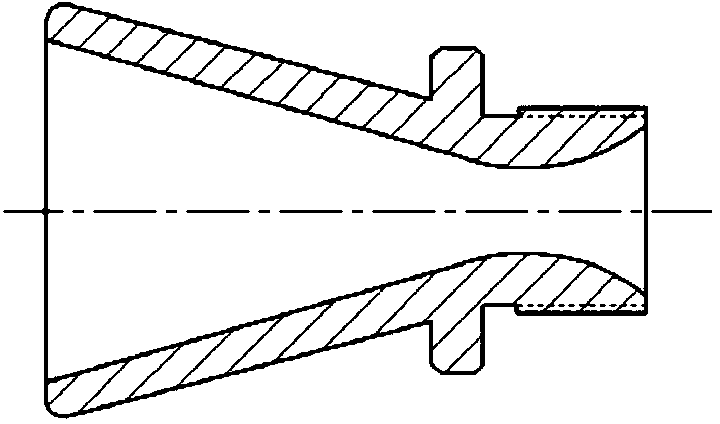

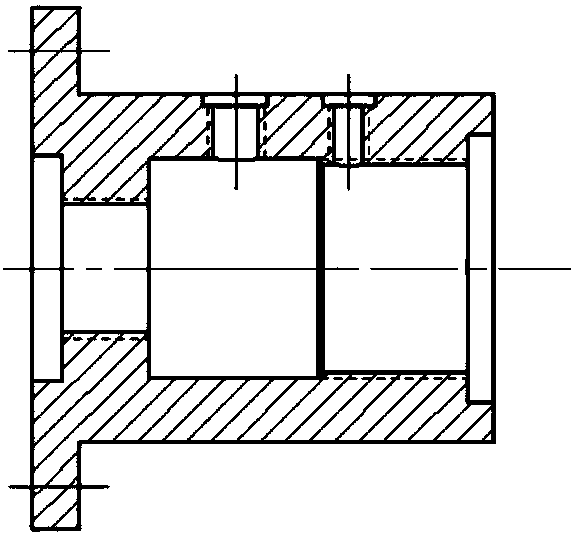

[0029] Such as figure 1 As shown, the sliding arc ignition device of the present invention includes a contraction-expansion type Laval nozzle 2, a casing 4, an airflow baffle 5, an electrode mounting seat 8, a high-voltage anode 10 and a lock nut 11, and the contraction-expansion type Laval nozzle The Val nozzle 2 and the electrode mounting seat 8 are fixed on the casing 4 through threads, and the oil vapor fuel inlet 6 and the auxiliary gas inlet 7 are arranged on the casing 4, and the airflow baffle 5 is clamped between the casing 4 and the electrode mounting seat 8 , the high-voltage anode 10 is inserted into the center hole of the electrode mounting base 8, and the end of the high-voltage anode 10 has an external thread for connecting the lock nut 11. The high-voltage anode 10 is fixed and locked on the electrode mounting base 8 by bonding the sealant and the lock nut 11

[0030] The flame connection pipe 1 is installed on the engine or equipment casing support to form a ...

Embodiment 2

[0040] According to different ignition flame flow modes, this embodiment adopts contraction-expansion type Laval oblique nozzle, such as Figure 9 Shown, to adapt to ignition requirements, all the other parts are identical with embodiment 1.

Embodiment 3

[0042] This embodiment adopts another kind of airflow baffle, such as Figure 10 Shown, all the other parts are identical with embodiment 1.

[0043] As can be seen from the above description, the above-mentioned embodiments of the present invention have achieved the following technical effects: by introducing the auxiliary gas source of the sliding arc, a sliding arc of a certain energy intensity is generated at the central high-voltage anode and the inner wall of the Laval nozzle, The inlet introduces combustible gas or a mixture of oil and gas with a certain ratio. When it passes through the arc area, it ignites and burns. The flame sprays out of the nozzle and is separated from the nozzle by the blowing of the airflow. There is a certain distance between the defire zone, and the ignition device is at a low temperature. Under the action of the arc, the fuel can be pre-catalyzed and then sprayed into the combustion chamber to play a role in continuous combustion. Since the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com