An ignition system for pulse detonation engine

A technology of pulse detonation and ignition system, applied in the field of ignition system, can solve the problems of affecting the operating frequency of the engine, large ignition delay time, and small spark plug ignition energy, so as to shorten the ignition delay time, shorten the time and distance, and increase the operating frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

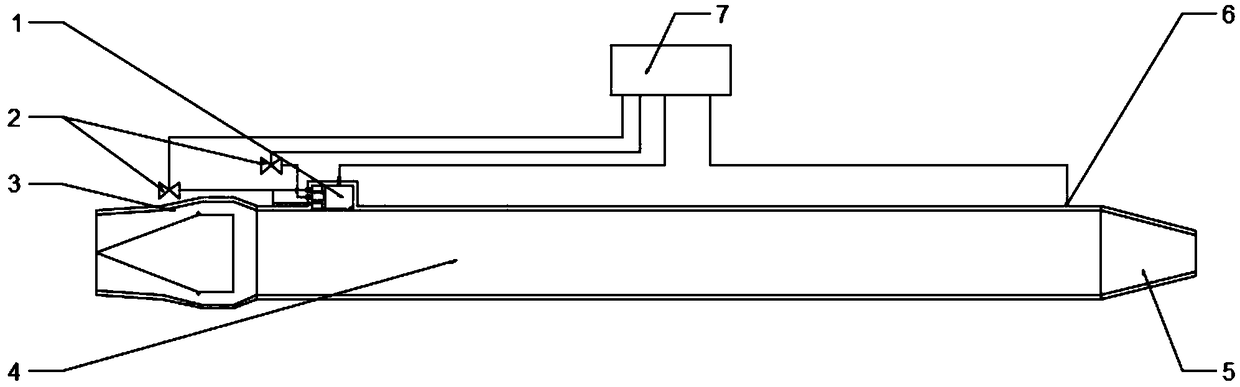

[0027] Such as figure 1 As shown, an ignition system for a pulse detonation engine includes a jet generator 1, a pulse detonation engine and a control system 7; the pulse detonation engine includes a detonation chamber 4, an air intake chamber 3 and an exhaust injection chamber 5. One end of the detonation chamber 4 communicates with the intake chamber 3, and the other end communicates with the tail spray chamber 5; the tail spray chamber 5 is provided with a gas detector 6 for detecting the gas concentration in the tail spray chamber 5; The jet generator 1 is installed on the detonation chamber 4 and is close to one end of the air intake chamber 3 .

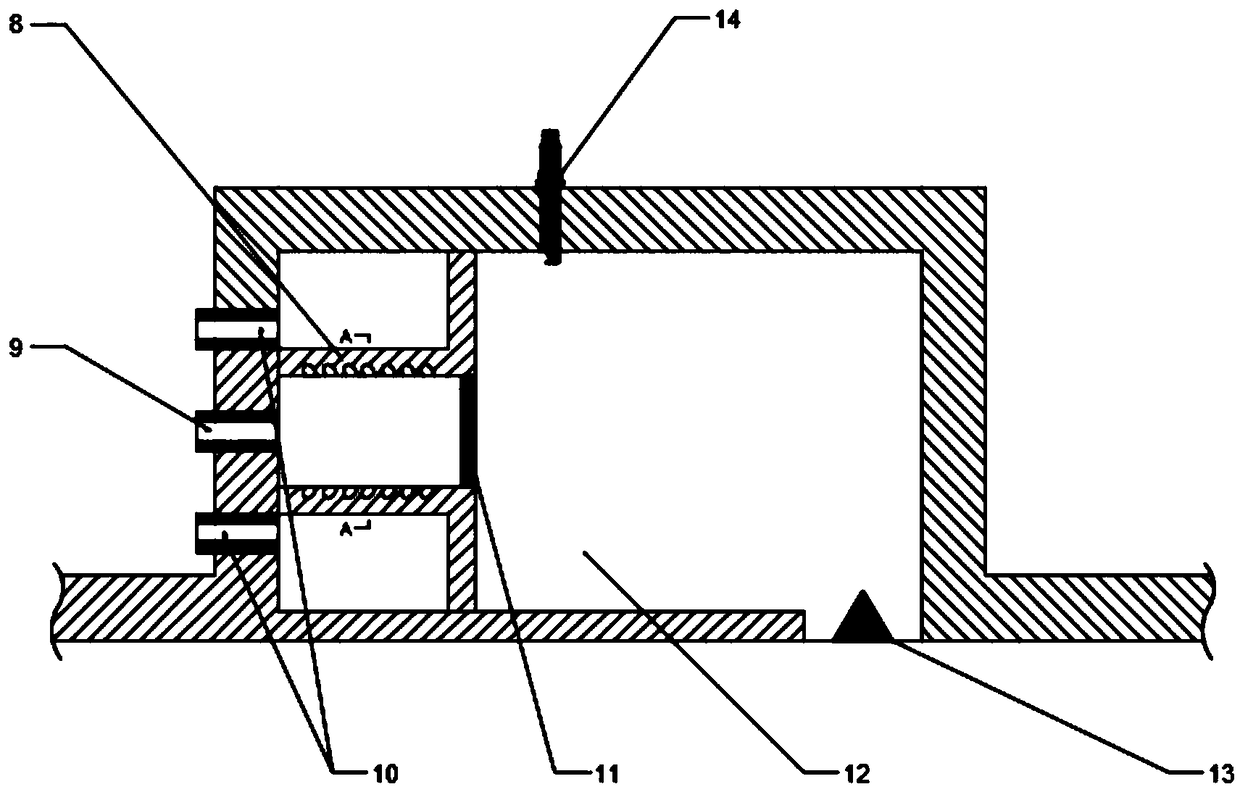

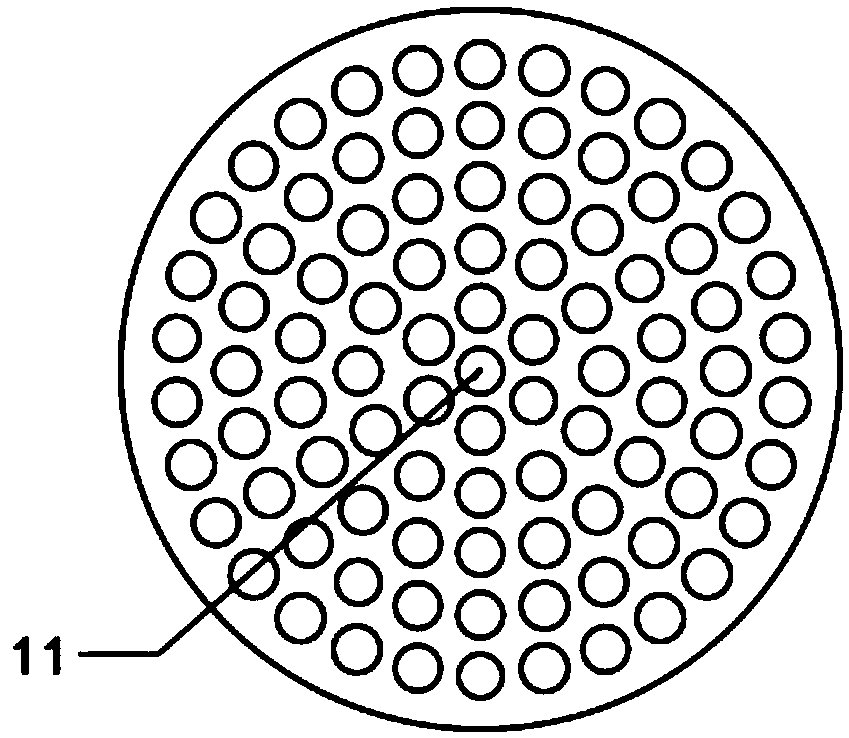

[0028] Such as figure 2 As shown, the jet generator 1 includes a jet cavity 12 and a fuel chamber, a sealing plate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com