Aeroengine plasma jet igniter based on self-bleed air

An aero-engine and plasma technology, which is applied to machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of heavy weight, complex structure, large volume, etc., to reduce weight, simplify intake structure, and achieve high ignition energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

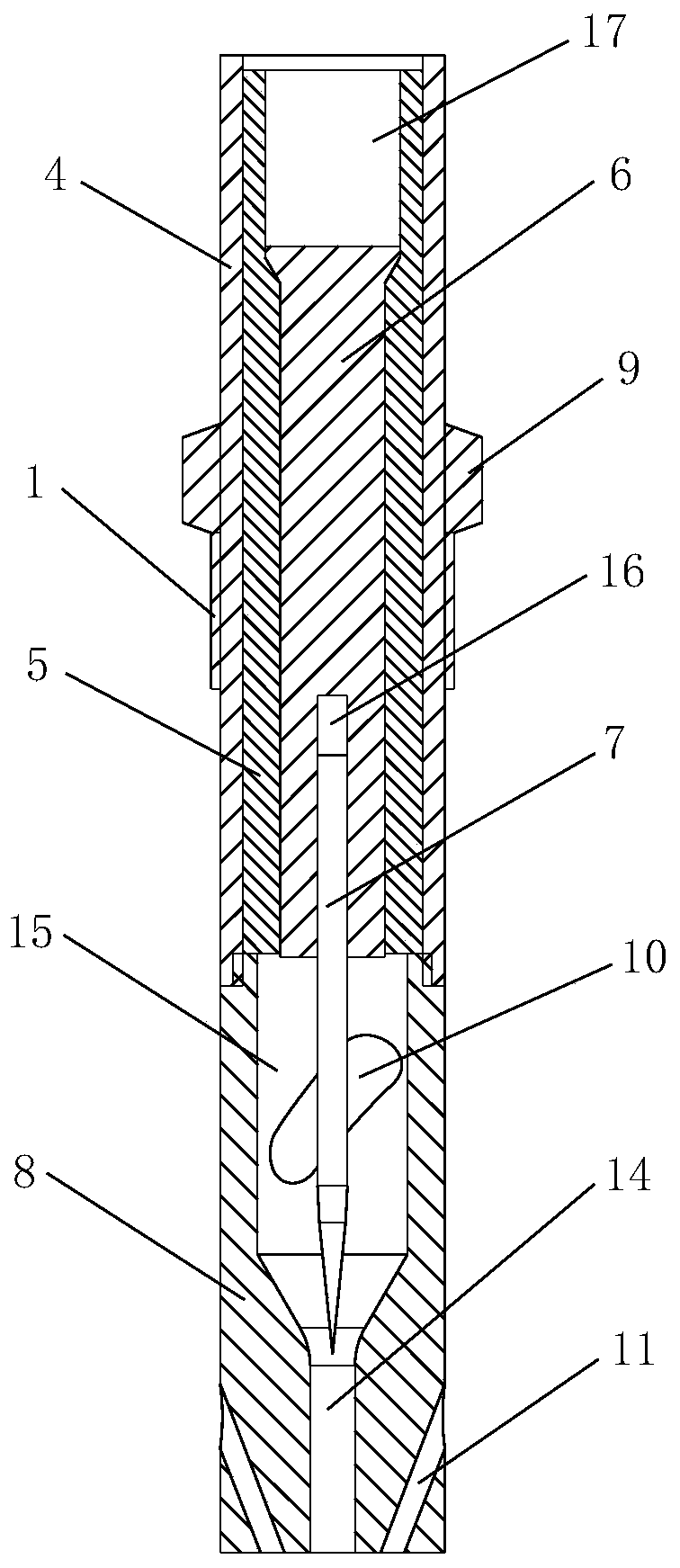

[0046] Such as Figure 1 to Figure 5 The shown aero-engine plasma jet igniter based on self-bleed air includes an outer tube 4, an insulating inner tube 5, a conductive copper tube 6, a cathode 7 and an anode 8, and the outer tube 4 is arranged above the anode 8 , the lower end of the outer tube 4 is fixedly connected to the upper end of the anode 8, the insulating inner tube 5 is set in the outer tube 4, the insulating inner tube 5 is a hollow rotating body, and the conductive copper tube 6 is set in the insulating inner tube 5, the head of the conductive copper tube 6 and the head of the insulating inner tube 5 form a stepped matching structure, and the tops of the outer tube 4, the insulating inner tube 5 and the conductive copper tube 6 jointly form a power connection interface 17, The bottom of the conductive copper tube 6 is provided with a groove 16 with an internal thread on the inner wall, and the top of the cathode 7 is screwed to the groove 16. The outer tube 4, the...

Embodiment 2

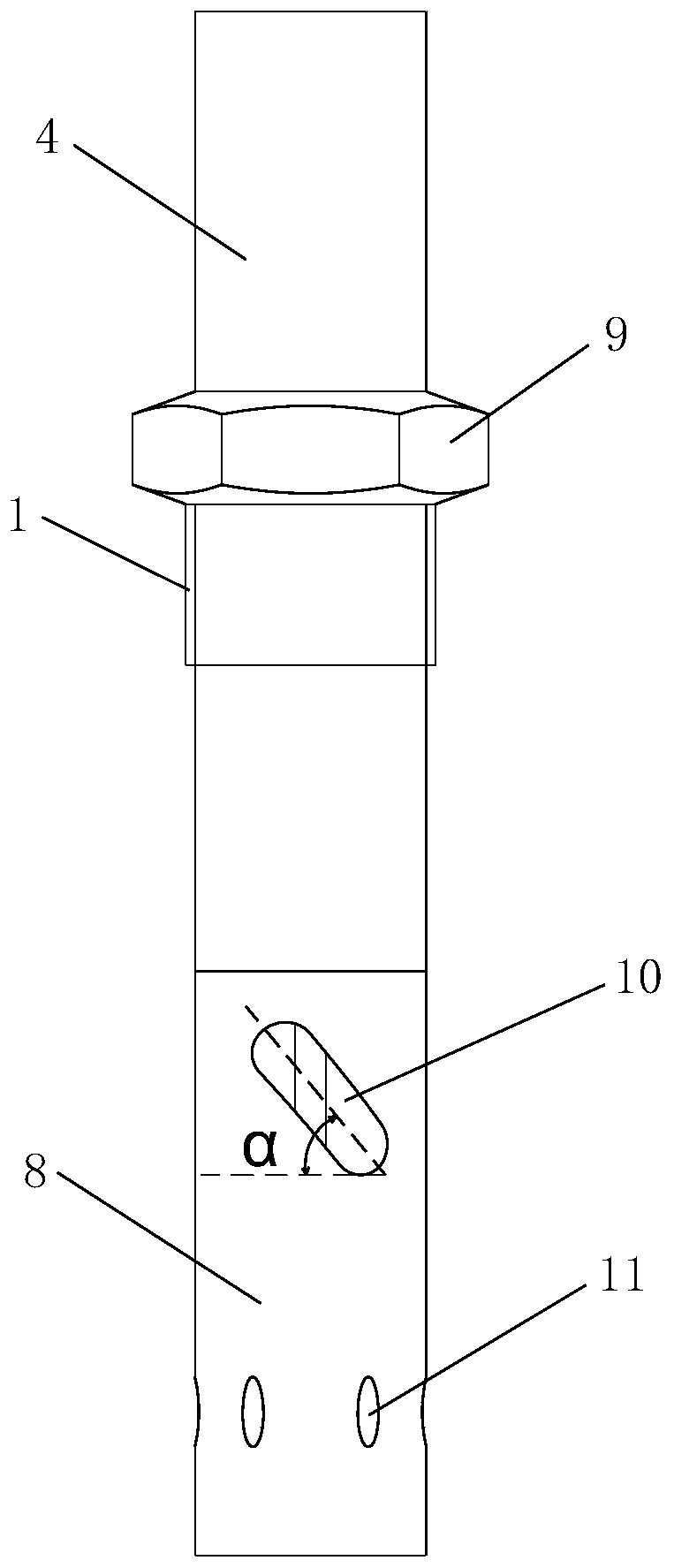

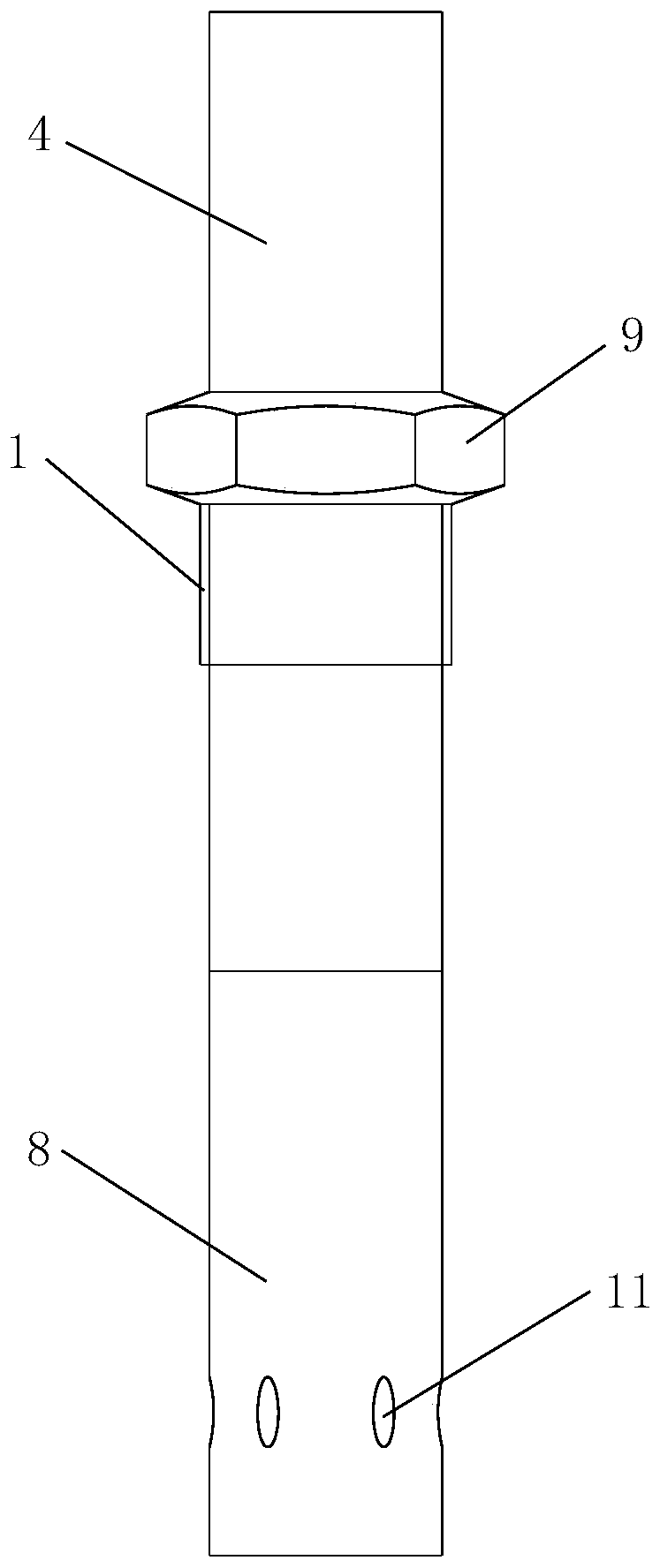

[0064] Such as Figure 6 to Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the air inlet 10 of the igniter is a chute structure, and the air inlet 10 of the igniter is in the shape of a vane. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0066] Such as Figure 9 to Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that: the air inlet 10 of the igniter is composed of a plurality of meshes arranged in a rectangular array; the angle between the meshes and the horizontal plane is 0°.

[0067] In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com