Vertical two-stage rotary compressor for refrigerator and working method thereof

A rotary compressor, compressor technology, applied to elastic fluid rotary piston type/swing piston type pump combination, rotary piston type/swing piston type pump components, mechanical equipment, etc., can solve the problem that cannot be used directly The oil circuit system of the vertical rotary compressor affects the stability of the refrigerator system and the wear of the compressor increases, so as to effectively control the airflow fluctuation and noise, save the design space and reduce the design height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

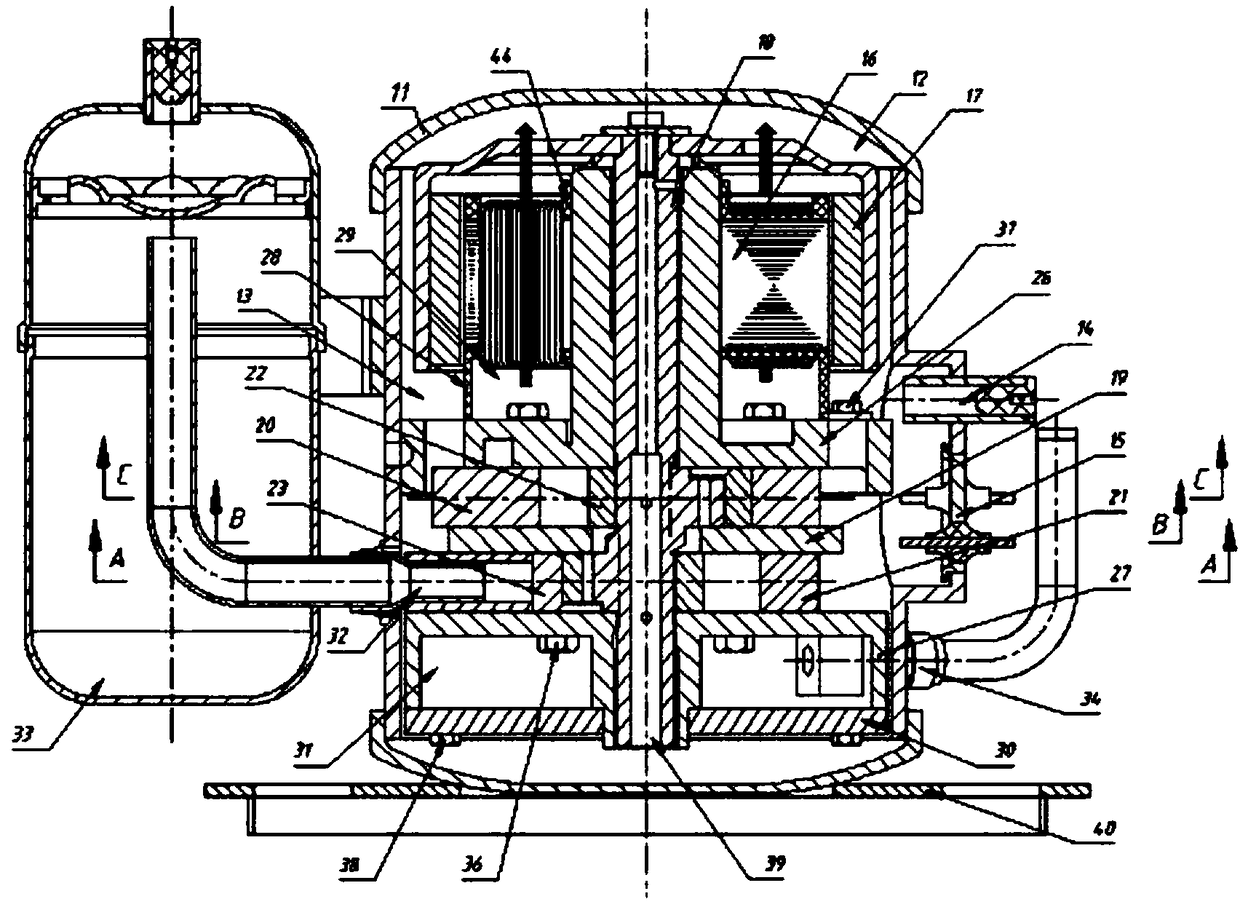

[0036] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is a vertical two-stage rotary compressor for refrigerators, including a housing 11, an outer rotor motor 12 housed in the inner space of the housing 11 and a pump driven by the outer rotor motor 12. body 13,

[0037] The side of the middle part of the housing 11 is provided with an exhaust pipe 14 and a sealed socket assembly 15 for supplying power to the outer rotor motor 12;

[0038] The outer rotor motor 12 is composed of a stator 16 and a rotor 17 outside the stator 16;

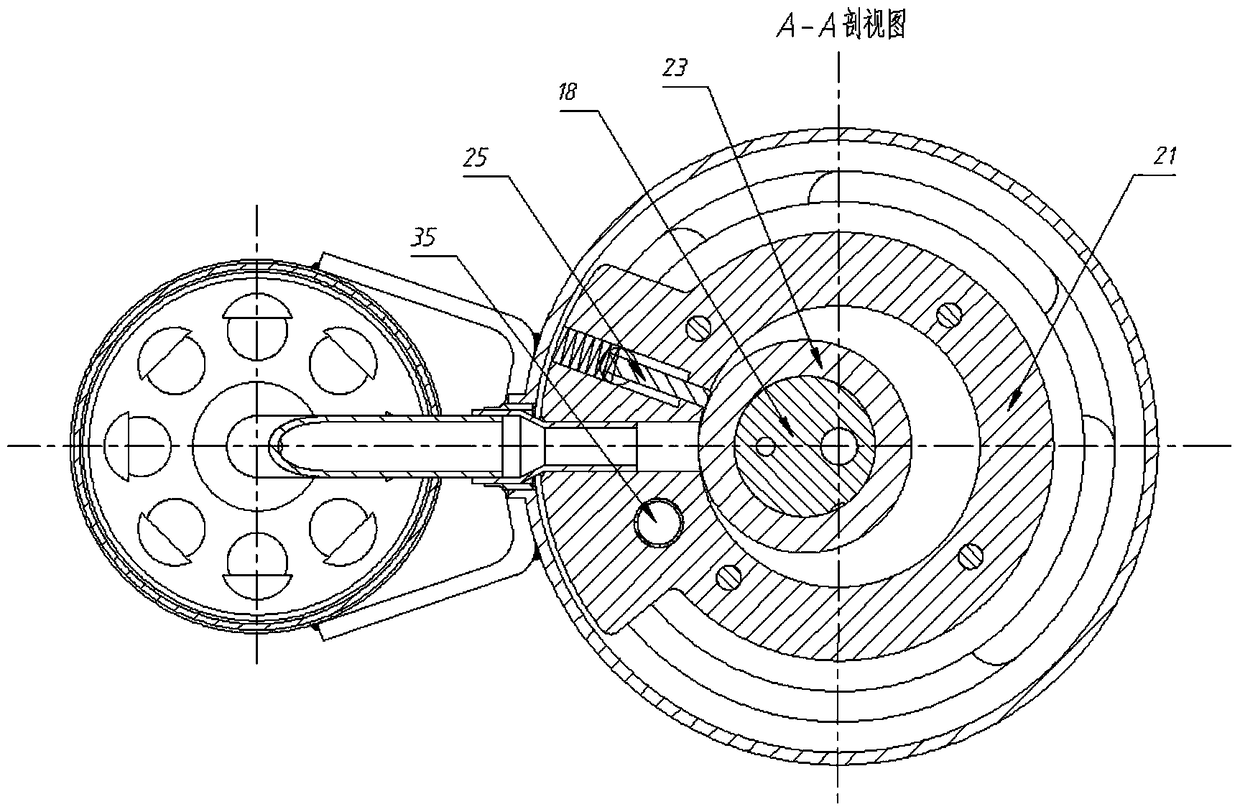

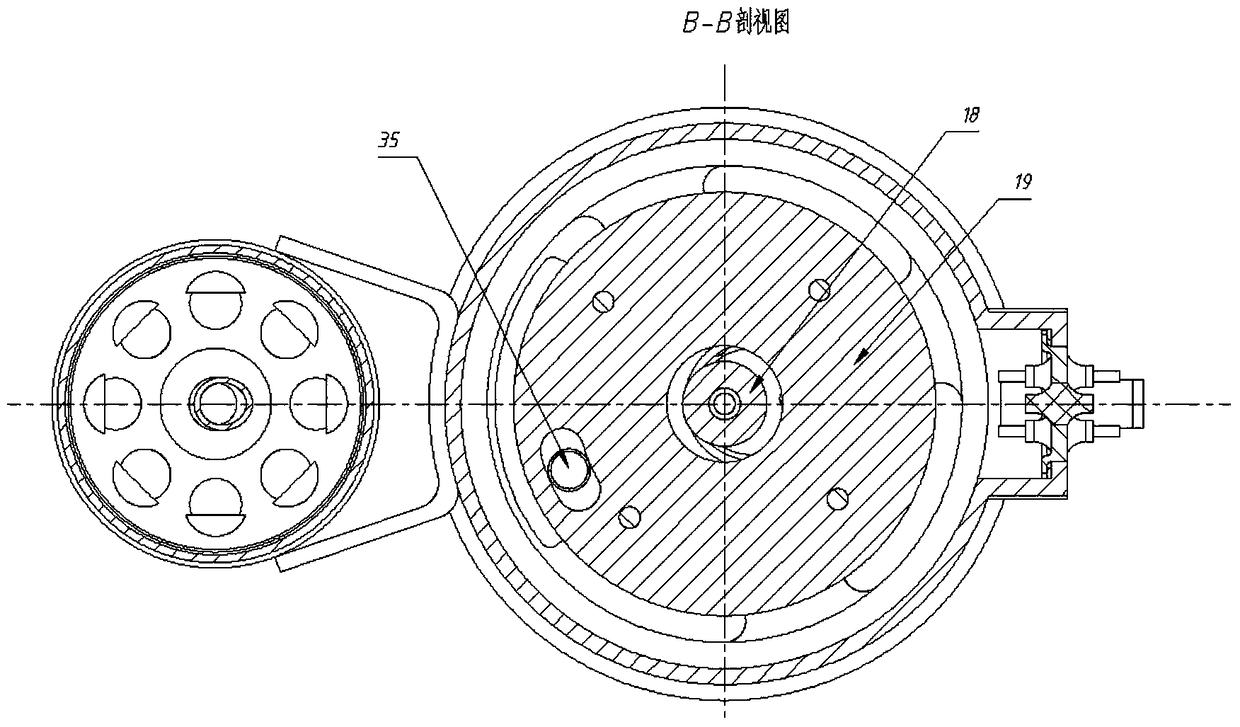

[0039]The pump body 13 includes a crankshaft 18 extending vertically in the center of the pump body and an intermediate partition 19, an upper cylinder 20 arranged on the top of the intermediate partition 19, a lower cylinder 21 at the bottom of the intermediate partit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com