A Plasma-Based Orbital Sliding Arc Actuator

A plasma and exciter technology, which is applied in the direction of plasma, machine/engine, electrical components, etc., can solve the problems of plasma sliding arc and air in the outer channel, contact time of atomized fuel is short, discharge area is limited, etc. , to achieve the effect of widening the flameout boundary, reducing combustion pollutant emissions, and reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

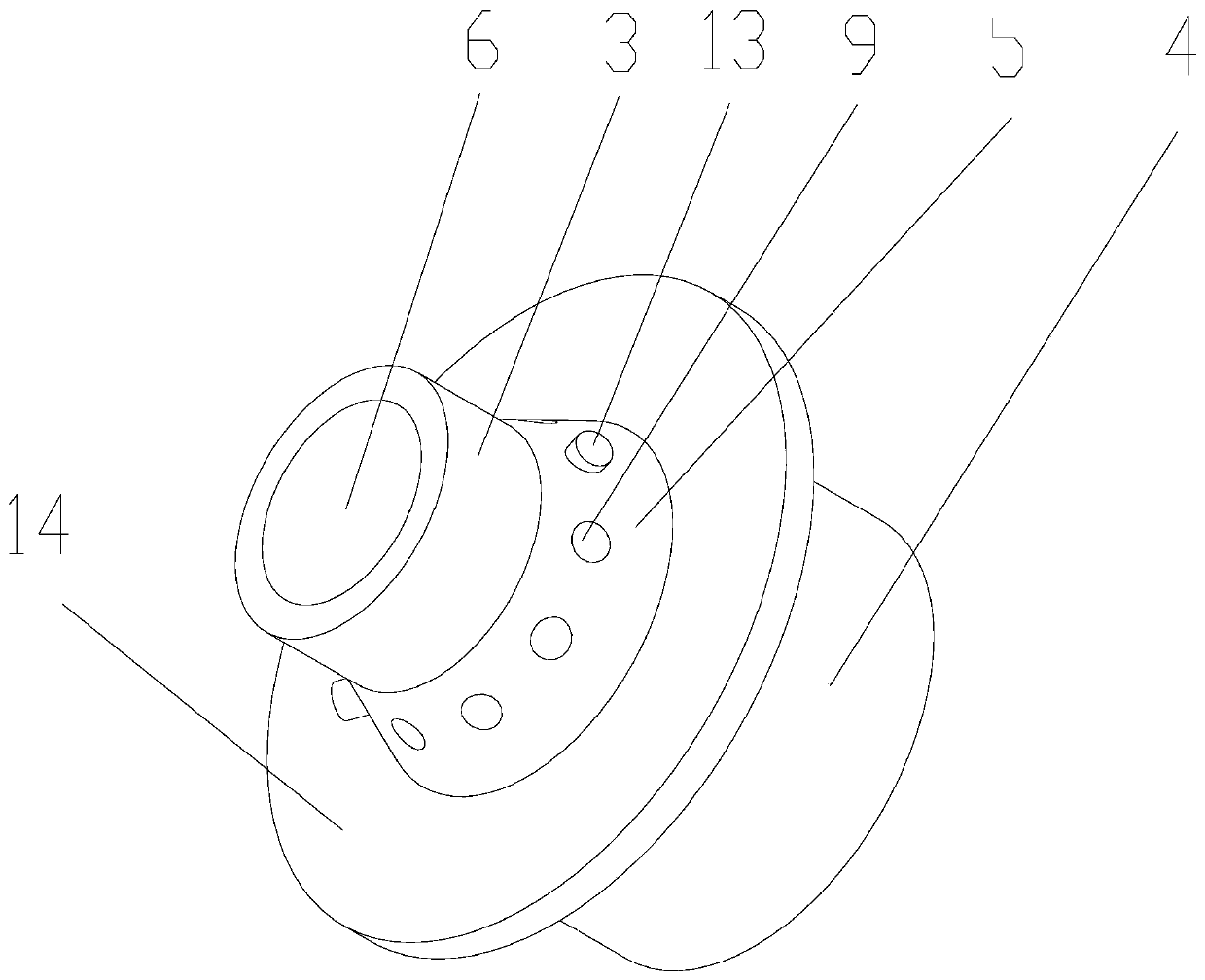

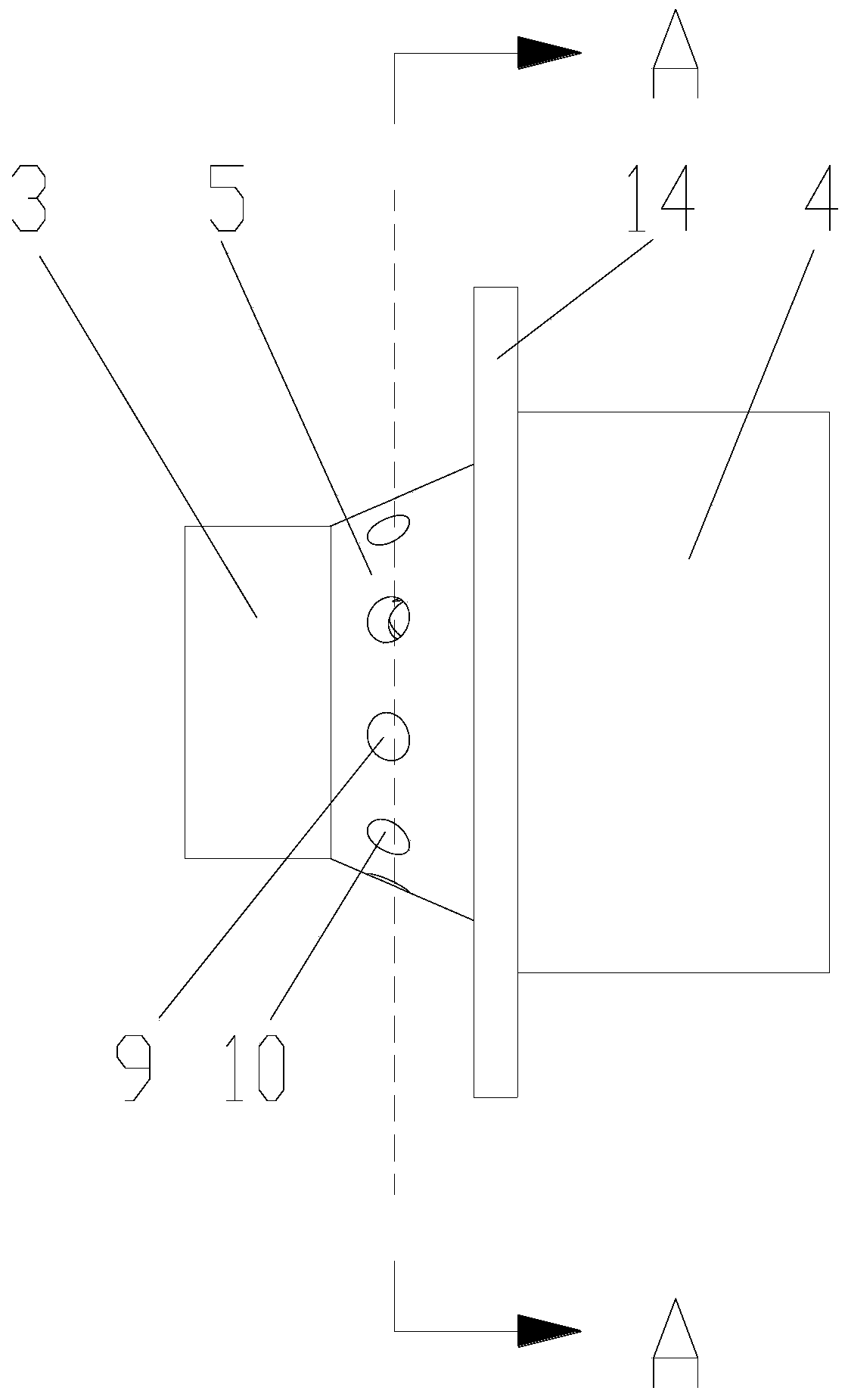

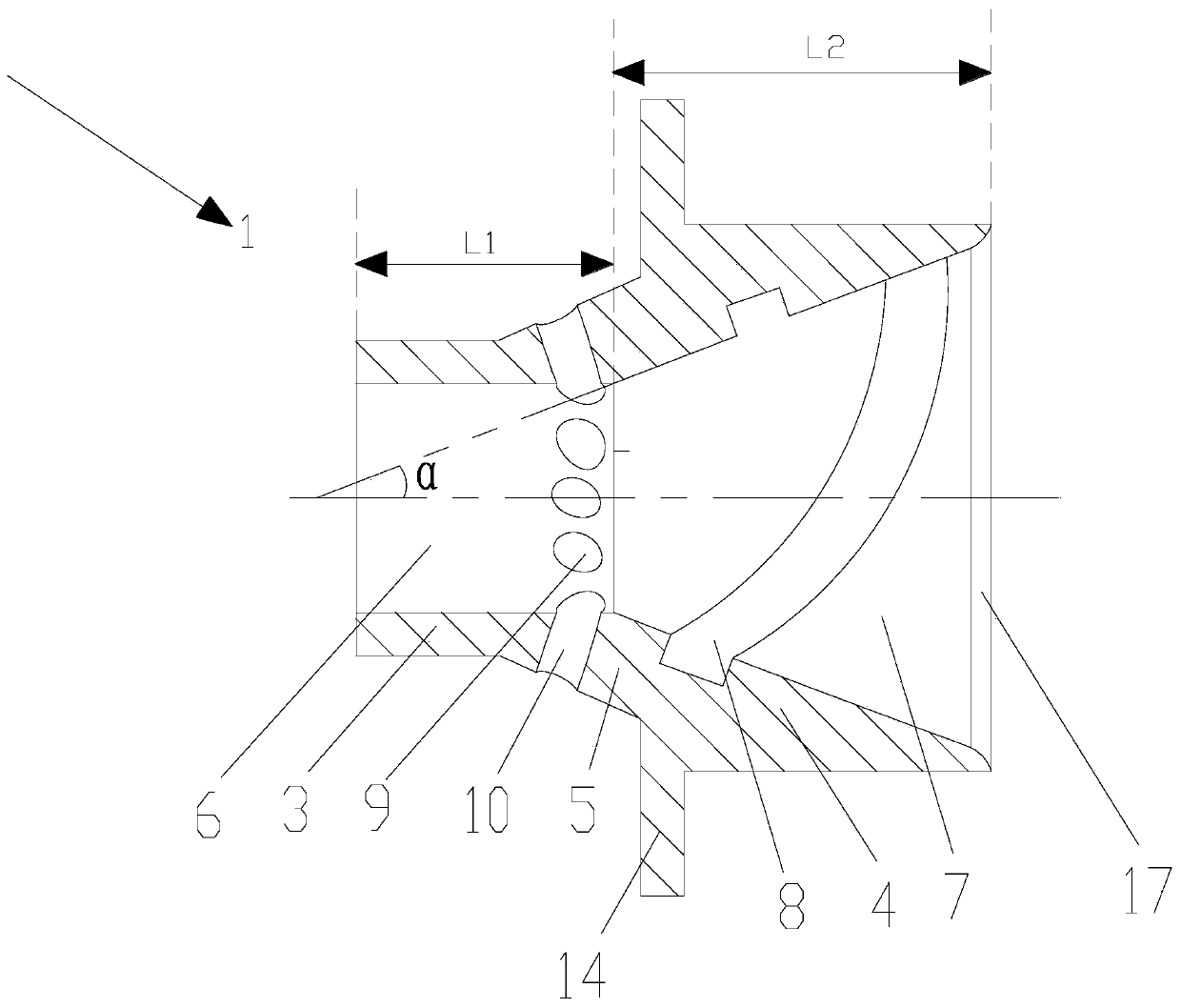

[0049] Such as figure 1 , figure 2 , image 3 with Image 6 As shown, a plasma-based orbital sliding arc exciter includes an exciter body 1 and two electrodes 2 with the same structure and used to generate arcs. The exciter body 1 includes first joints 3, The swirl joint 5 and the second joint 4, the first joint 3, the second joint 4 and the swirl joint 5 are integrally formed, and the axes of the first joint 3, the swirl joint 5, and the second joint 4 are uniform on the same straight line.

[0050] Such as figure 1 , image 3 , Figure 5 with Image 6 As shown, the interior of the first joint 3, the swirl joint 5 and the second joint 4 are all hollow structures, and the internal hollow structures of the three jointly form an inner channel, and the inner channel includes a swirl flow for connecting fuel nozzles. The channel 6 and the diffusion channel 7 used to connect the combustion chamber of the engine, the swirl channel 6 is a cylindrical channel, and the diffusi...

Embodiment 2

[0065] Such as Figure 10As shown, the difference between this embodiment and Embodiment 1 is that the cross-sectional shape of each of the electrode grooves 8 is square and the cross-sectional area of one of the electrode grooves 8 is larger than the cross-sectional area of the remaining electrode grooves 8. Each of said electrodes 2 is a rectangle 19 in cross-sectional shape, and the length of each said electrode 2 cross-section is equal to the width of its correspondingly installed electrode slot 8, and the width of each said electrode 2 cross-section is corresponding to its correspondingly installed electrode slot. 2 have the same depth, and the electrodes 2 are all arranged inside the electrode groove 8, so as to reduce the influence of air on the arc without affecting its discharge. The electrode 2 is matched with the inner side of the electrode groove 8 and the part of the electrode 2 in contact with the electrode groove 8 is adhered, and the outer end of the termin...

Embodiment 3

[0069] Such as Figure 11 As shown, the difference between this embodiment and Embodiment 1 is that the cross-sectional shape of each electrode slot 8 is square, equal in size, and identical in structure, and the electrodes 2 are disposed inside the electrode slot 8 by casting.

[0070] In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com