Method and device for recycling methane in membrane hydrogen extraction tail gas

A technology for membrane extraction of hydrogen and tail gas, applied in refrigeration and liquefaction, climate sustainability, lighting and heating equipment, etc., to achieve the effect of improving energy saving measures, reducing resource consumption, and improving comprehensive energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

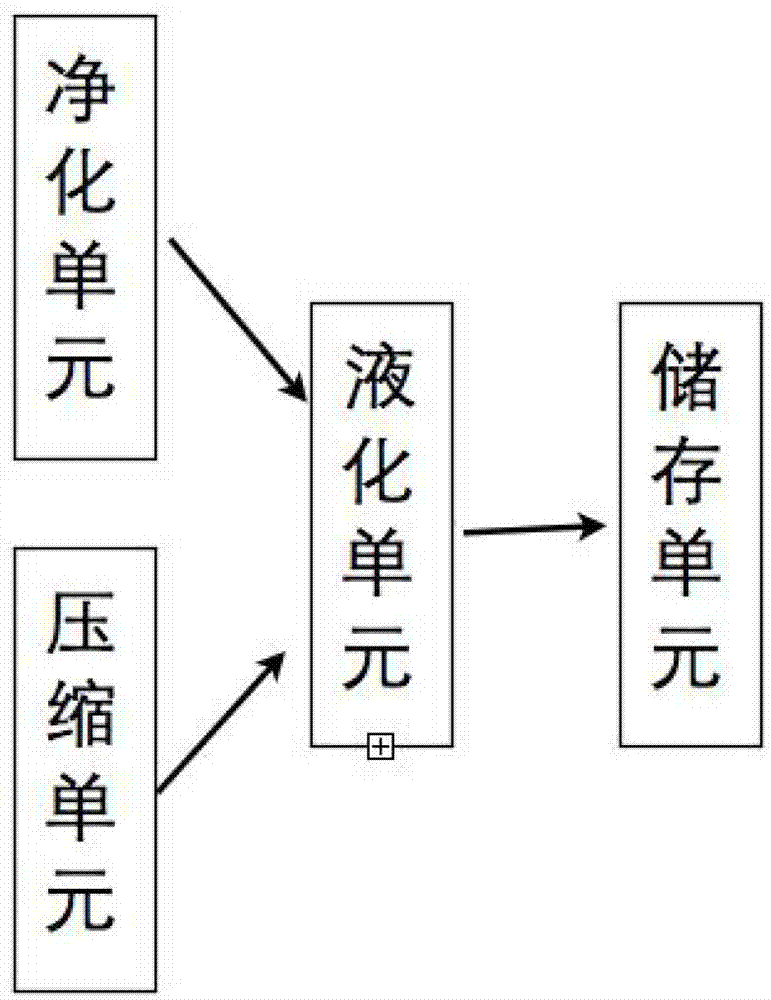

[0038] The present invention provides a method and device for recovering methane from membrane hydrogen extraction tail gas, including purification operation, compression operation, liquefaction operation and storage operation; wherein,

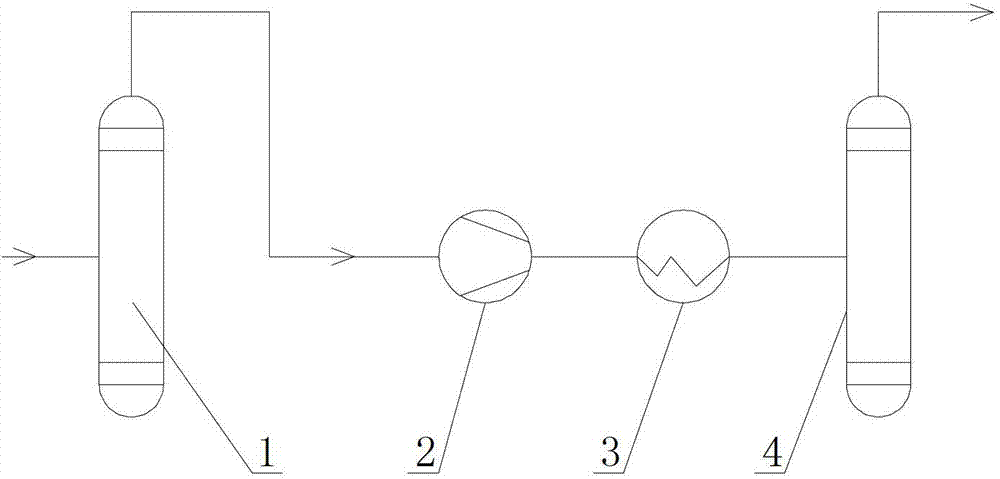

[0039] Purification operation is used to operate the raw material gas and transport the purified gas to the liquefaction operation; the purification operation may include a drying tower and a filter; the raw material gas is removed from the H after passing through the drying tower 2 0, enter the liquefaction operation after dust pretreatment through the filter.

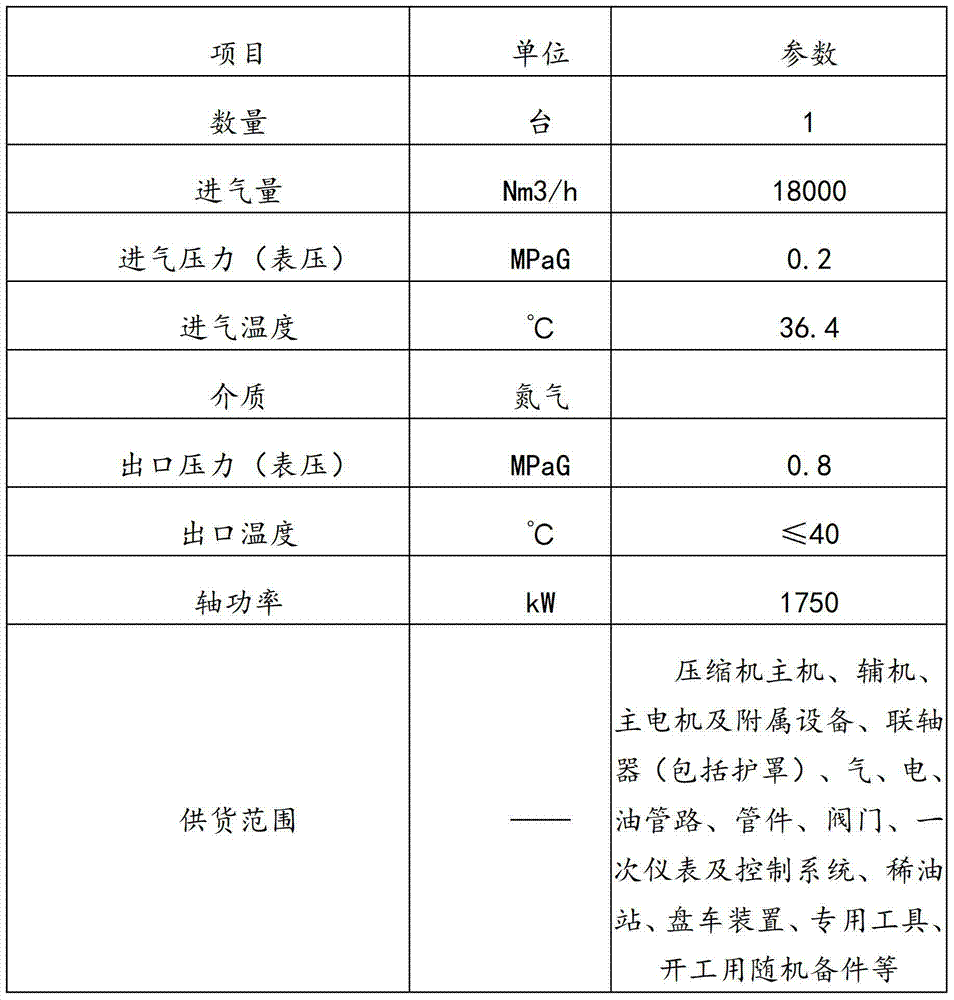

[0040] In concrete oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com