Matrix standard correction-gas chromatography-mass spectrum combination assay method for 12 types of phthalic acid ester in hot melt adhesive

A phthalate and gas chromatography technology, applied in the field of hot melt adhesive chemical composition determination, can solve problems such as lack of research and detection methods, and achieve simple and effective methods, high extraction efficiency, good repeatability and recovery rate Effect

Active Publication Date: 2014-07-16

CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

View PDF2 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Hot-melt adhesives are widely used in the fields of wood and paper material binding, vehicles, ships, and building interior decoration, and there is a po

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Example Embodiment

[0070] Example 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionization energy | aaaaa | aaaaa |

Login to View More

Abstract

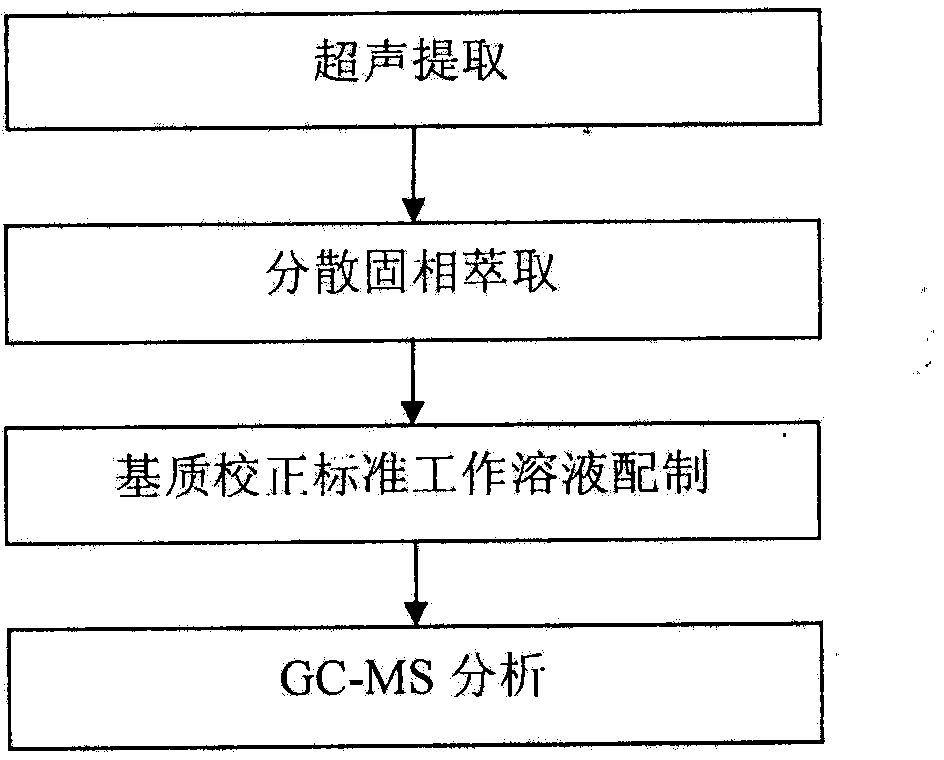

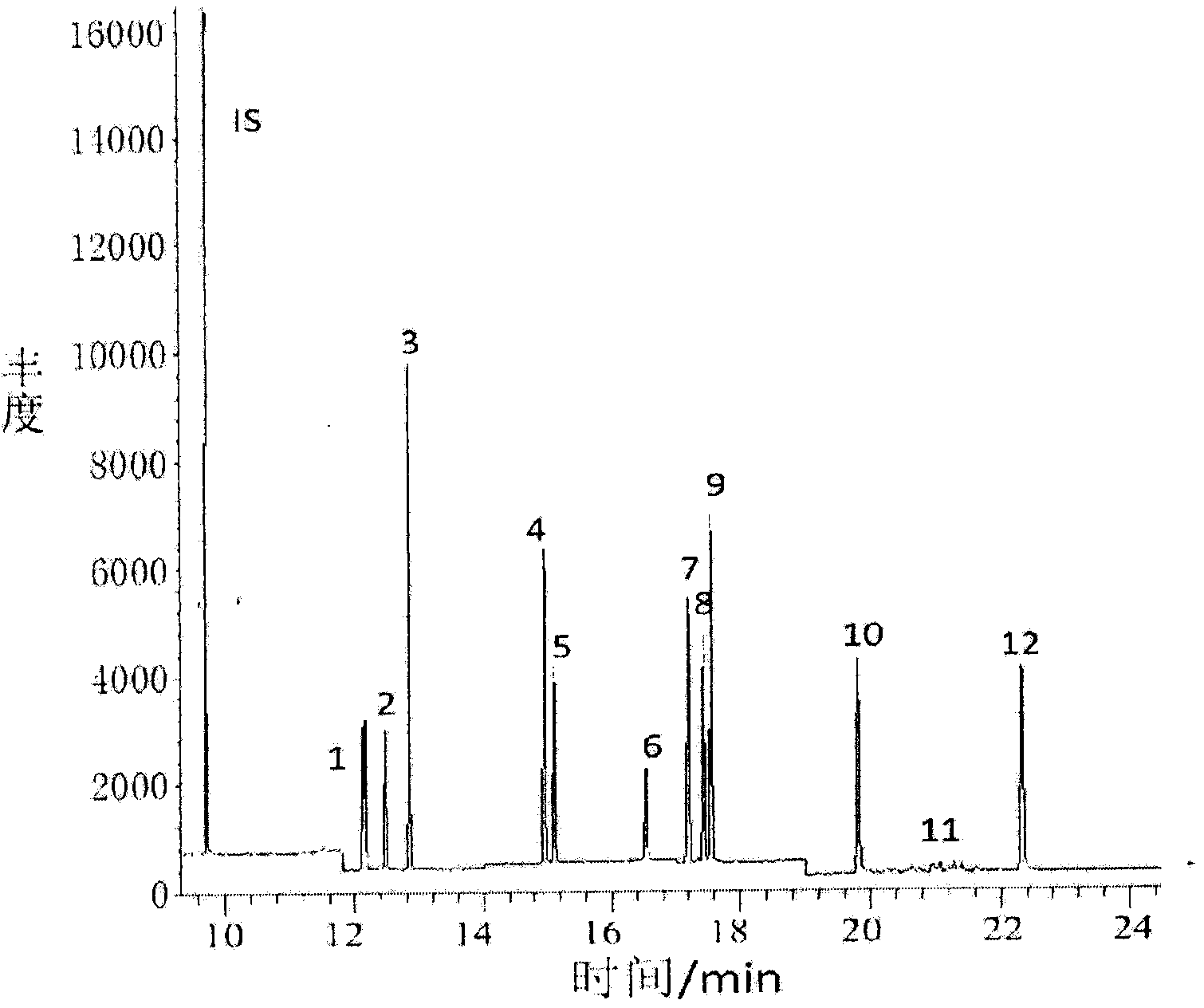

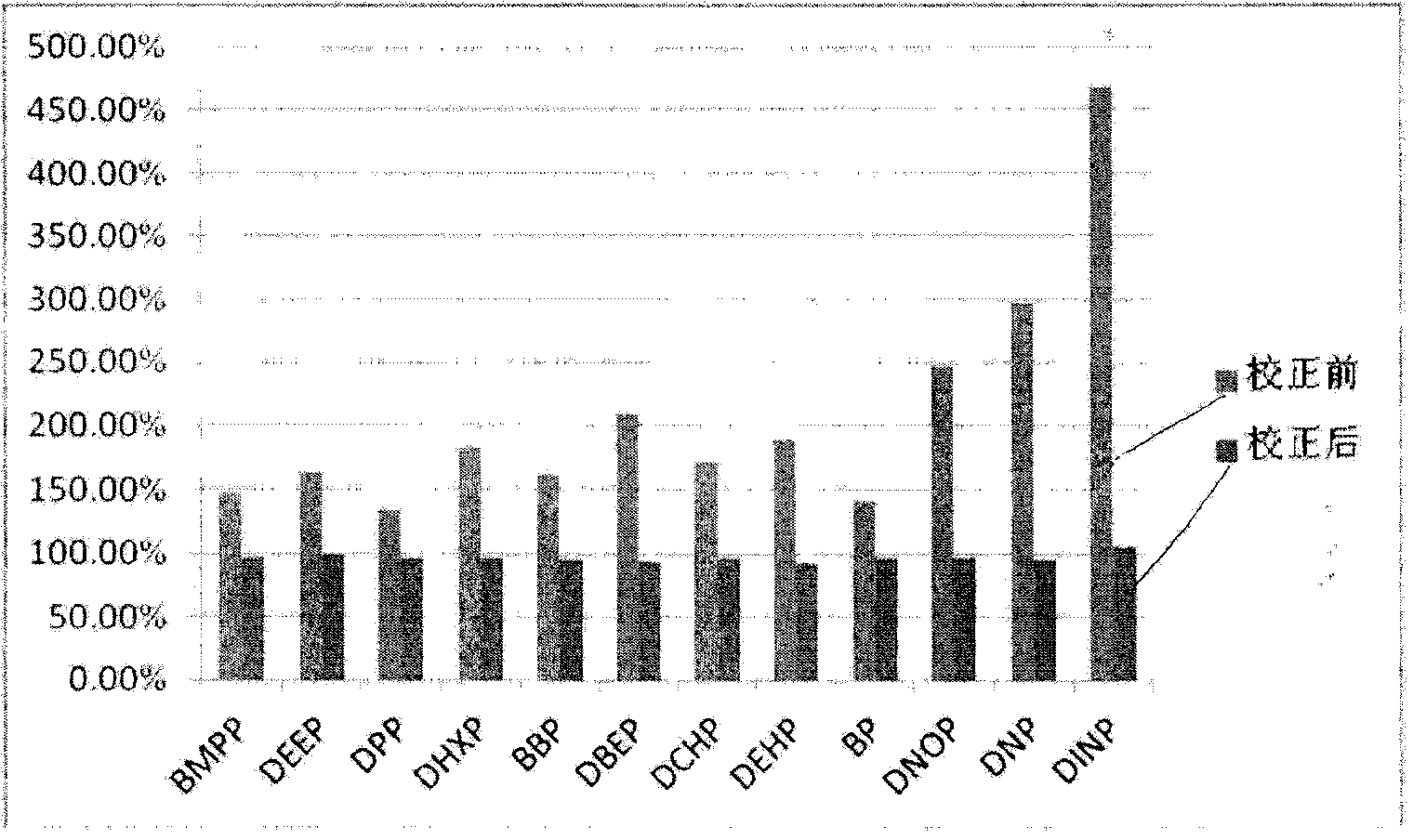

The invention discloses a matrix standard correction-gas chromatography-mass spectrum combination assay method for 12 types of phthalic acid ester in a hot melt adhesive. The method is characterized by comprising the following steps: cutting a hot melt adhesive sample into pieces by use of scissors, putting into n-hexane, extracting under ultrasonic wave, treating a liquid supernatant through centrifugation-dispersion solid-phase extraction and purification, and subsequently quantitatively detecting the content of the 12 types of phthalic acid ester in the hot melt adhesive by adopting an internal standard method by use of a matrix standard correction-gas chromatography-mass spectrometry (GC/MS). The method has the advantages of simplicity, convenience, rapidness, high sensitivity and good repeatability; the detection limit is 0.3-16.0 mg/kg, the limit of quantitation is 0.8-48.0 mg/kg, the average adding standard recovery is 92.13%-103.13%, and the mean relative deviation (RSD) is 3.84%-13.74%.

Description

[0001] Technical field [0002] The present invention involves the method of measurement method of hot melting glue chemical composition, which specifically involves the test method of the base standard correction of 12 types of phenyl acid ester in a hot melting glue-Qi phase chromatography-mass spectrometry combined method. [0003] Background technique [0004] Diabenate (PAES) is commonly used in toys, food packaging materials, ethylene flooring, wallpaper, cleaner, lubricant, and personal care products (Anal BioanalChem, 2003, 375: 527 ~ 533.).PAES is a type of endocrine interference hormone that can cause cell mutations, cancer and teratogenic. It is confirmed in the study of in vitro toxic science to have the effect of weak estrogen, which can cause damage to the male reproductive systemA series of male reproductive toxicity such as reducing and genital malformations, and increasing the incidence of female breast cancer (Environment. Health. Perspect., 2003, 111 (2): 139 ~...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N30/02G01N30/06G01N30/14

Inventor 韩书磊杨飞陈欢刘彤吴帅宾侯宏卫胡清源

Owner CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com