Cooling device

A heat dissipation device and heat dissipation pipe technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electric solid devices, etc., can solve the problems of affecting the service life of the heat dissipation device, poor heat dissipation effect of the heat dissipation device, etc., and achieve good heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

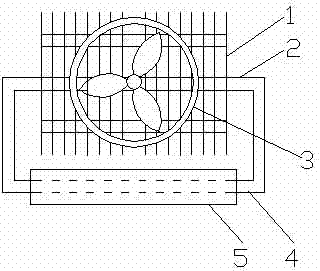

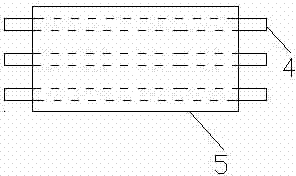

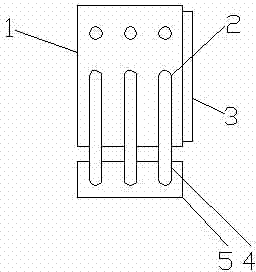

[0019] The present invention is described in further detail in conjunction with accompanying drawing, as figure 1 , figure 2 , image 3 As shown, three heat-absorbing pipes 4 are inlaid on the bottom plate 5, and a plurality of cooling fins 1 are connected to the three heat-dissipating pipes 2; Filled with a fluid heat-absorbing medium. The fluid heat conduction medium is R134A, R410A and the like.

[0020] The bottom plate 5 can be set according to the surface of the device to be dissipated, and the bottom plate 5 can be set in a shape matching the surface of the device to be dissipated, such as a flat plate. The bottom plate can be made of aluminum alloy plate. The radiating pipe and / or the heat absorbing pipe are made of copper pipes.

[0021] The number of heat dissipation pipes and heat absorption pipes can be set according to actual heat dissipation requirements. A plurality of circuits can be formed by connecting the heat-absorbing pipes and the heat-dissipating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com