A cleaning device after peeling off the insulation and shielding layer of high-voltage cables

A high-voltage cable and cleaning device technology, which is applied in the direction of circuits, electrical components, circuit/collector components, etc., can solve problems such as difficult scraping of the main insulation surface, hidden dangers of discharge, and weakening of the main insulation, so as to avoid improper selection of sandpaper , easy operation and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

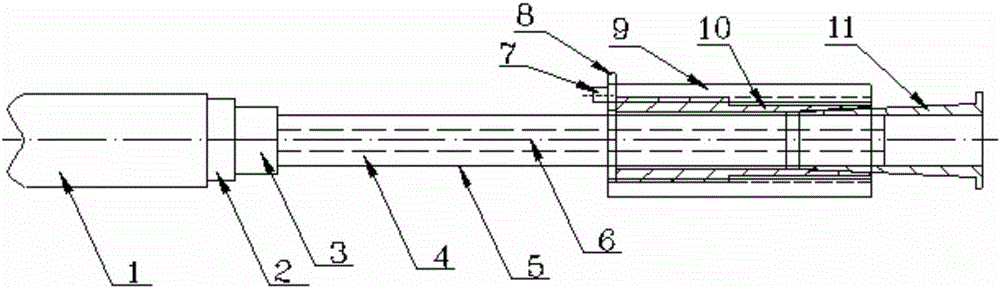

[0014] Below in conjunction with accompanying drawing, the present invention will be further described

[0015] The basic principle of the cleaning device after the high-voltage cable shielding layer is stripped: use the tubular nut structure to construct a cutting mechanism on the main insulating surface of the high-voltage cable to be cleaned, and complete the main insulating surface with a thickness of about 0.05mm by rotating the outer sleeve equipped with a glass cutter. Cutting, in order to achieve the purpose of cleaning thoroughly and smooth surface.

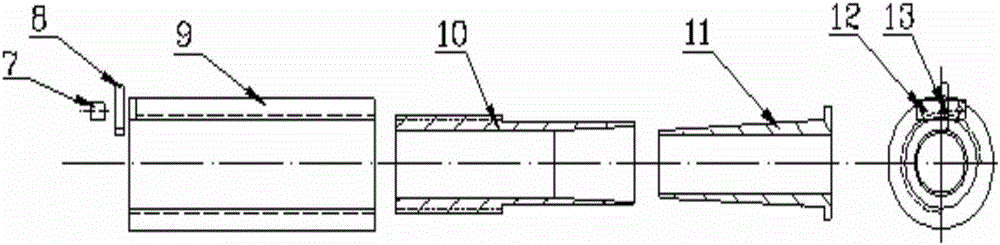

[0016] figure 1 Among them, the cleaning device after the high-voltage cable shielding layer is peeled off is composed of a cutter pressing plate 7, a cutter 8, an outer sleeve 9, an inner sleeve 10 and a fixed positioning sleeve 11, wherein the cutter pressing plate 7, the cutter 8, the outer sleeve 9, and the inner sleeve 10 Assembled together to form a cutting mechanism.

[0017] figure 2 Among them, the cutter 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com