Edible fungus automatic bagging, bagging, bagging, nest opening, stick insertion machine and method

An edible mushroom and integrated machine technology, which is applied in the field of nest opening, bagging, edible fungus automatic bagging, rod insertion machine, and bagging, to achieve the effects of liberating labor, improving reliability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

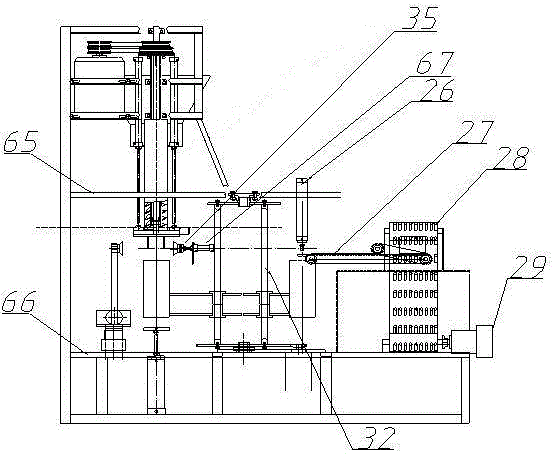

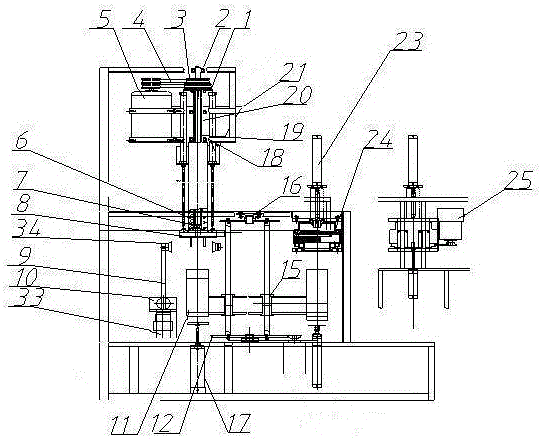

[0042] Refer to attached picture 1 , attached 2 The edible fungus automatic bagging, bagging, bagging, nest opening, and rod insertion machine is composed of: a lower frame 66 , on the rack 65 , the lower frame is equipped with a bearing bacteria bag sleeve 11 The station conversion mechanism and the bag taking and bag opening device , An automatic socket device is installed on the upper frame 24 , Automatic bagging device, automatic bagging device and automatic rod insertion device.

Embodiment 2

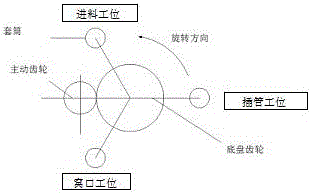

[0044] According to the embodiment 1 The edible fungus automatic bagging, bagging, bagging, nest opening, and stick insertion machine, refer to the accompanying drawings 2 , attached 4, The bag-taking, bag-opening device, automatic bag-carrying device, and automatic bag-filling device correspond to the charging station of the station conversion mechanism for carrying the bacteria bag sleeve, and the described automatic nest opening device corresponds to the described automatic pocket opening device. The socket station of the station conversion mechanism for carrying the bacteria bag sleeve corresponds to the socket station, and the automatic rod insertion device corresponds to the rod insertion station of the station conversion mechanism for the bacteria bag sleeve.

Embodiment 1

[0046] According to the embodiment 1 or 2 The edible fungus automatic bagging, bagging, bagging, nest opening, and stick insertion machine, refer to the accompanying drawings 1 , the station switching mechanism for carrying the bacteria bag sleeve is a multi-station conversion, and the active cylinder of the station switching mechanism for carrying the bacteria bag sleeve 17 with rotating chassis 12 A transmission mechanism is installed, and an optical shaft is installed on the rotating chassis 32 , a sleeve bracket is installed on the optical axis, a bacteria bag sleeve is installed on the sleeve bracket, and the bacteria bag sleeve is composed of two semi-cylinders, and the bacteria bag sleeve is There is an automatic opening and closing mechanism installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com