A production system for waist lining with rubber

A production system and waist lining technology, which is applied to the sewing tools, clothing, clothing, etc., can solve the problems of the waist lining and the tape not being neatly attached, the product quality needs to be improved, and the lack of pre-pressing treatment, etc., to achieve manual finishing The effect of shortening the process, saving processing workload, and good pre-pressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

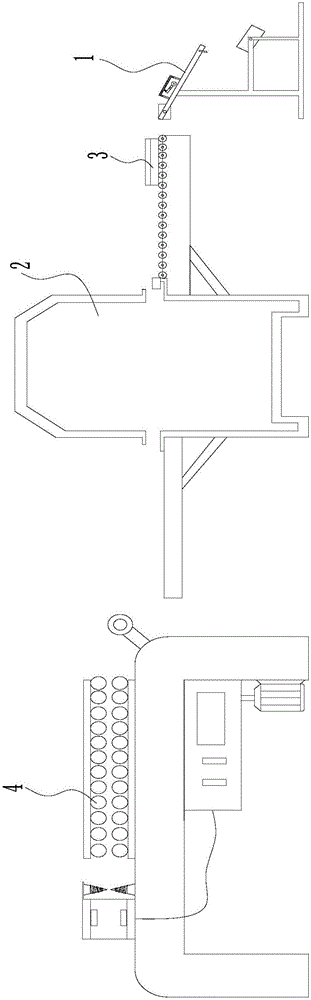

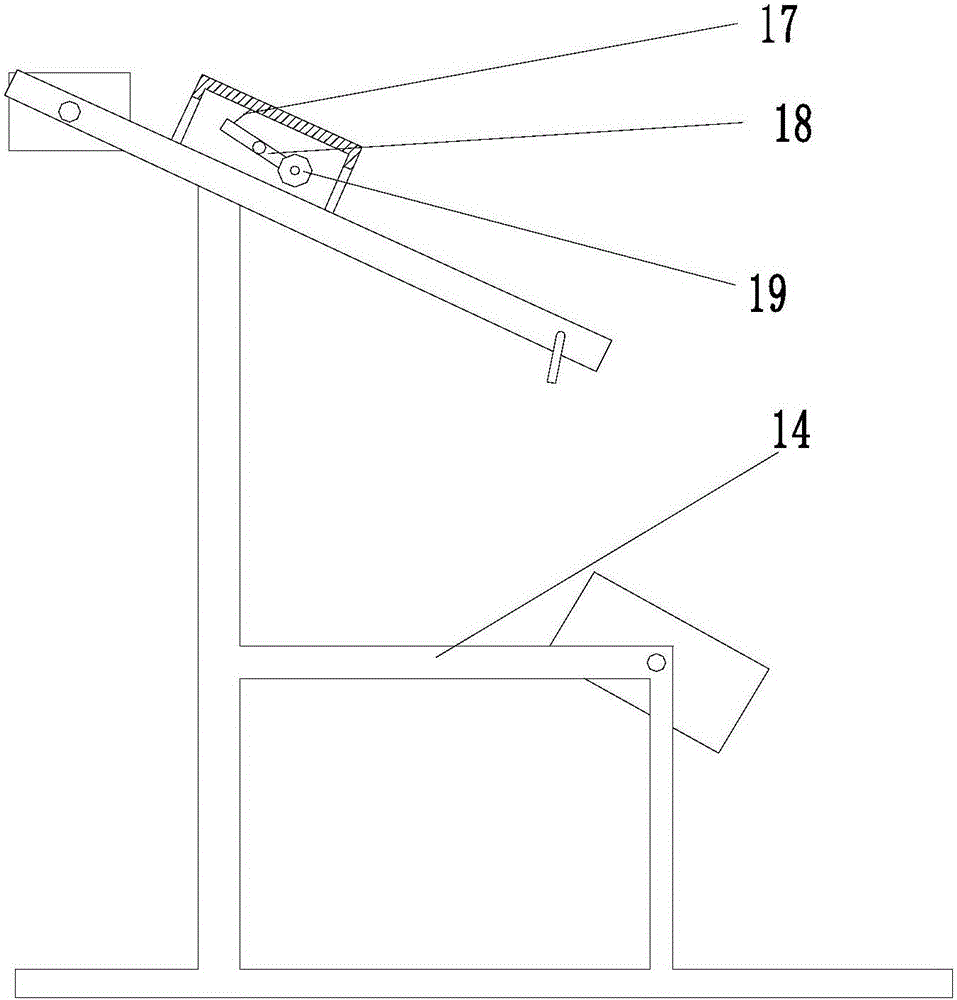

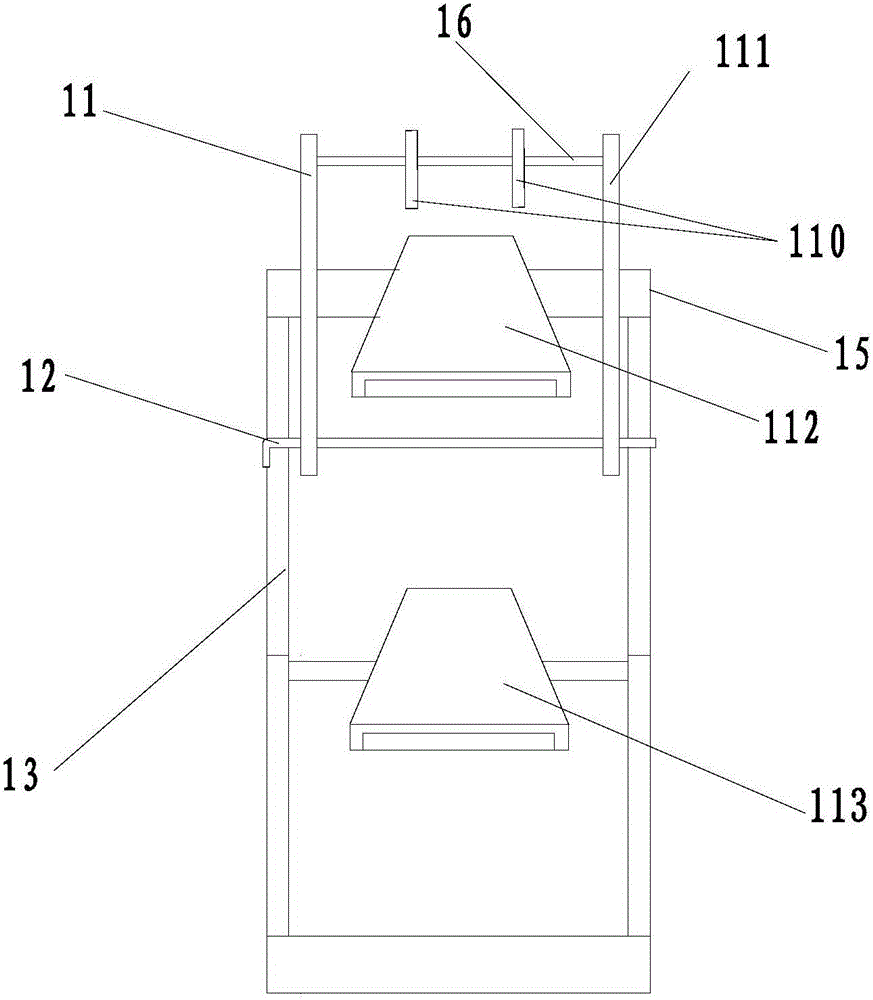

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10, a production system of the belted waist lining of the present invention, comprising a loading rack 1, a pre-pressing device 2, a hot pressing device 3 and a feeding device 4, the hot pressing device 3 is located between the feeding rack 1 and the feeding device 4, The hot pressing device 3 includes a heating element 31, a shaft roller conveying plate 32, a support device 34 and a plane conveying plate 35, a plane conveying plate 35 is installed on one side of the support device 34, and a plane conveying plate 35 is installed on the other side of the support device 34. Shaft-roller conveying plate 32 is installed, and several conveying rollers 36 are installed on described axle-roller conveying plate 32, and described pre-pressing device 2 is installed on the top of axle-roller conveying plate 32, and described pre-pressing device 2 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com