Gas purifying apparatus for pyrolyzed biomass fuel

A gas purification device and biomass fuel technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of waste of resources, inability to completely remove acid gas, etc., to improve the purification effect, prolong the purification time, The effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

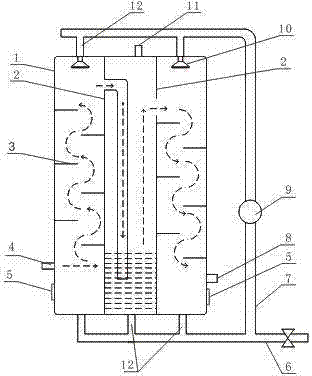

[0018] Such as figure 1 As shown, a gas purification device after pyrolysis of biomass fuel includes a square or cylindrical purification box 1, and two partitions 2 are arranged in the purification box 1, and the two partitions 2 clean the inside of the purification box. The space is divided into the first chamber, the second chamber and the third chamber from left to right. The top of the first chamber is provided with an atomizing rotary nozzle 10, and the lower end of the side wall of the first chamber is provided with an air inlet 4. ; The second chamber is provided with a ventilation pipe, and one port of the ventilation pipe communicates with the first chamber through the ventilation hole provided on the partition between the first chamber and the second chamber, and the other port stretches into the second chamber 7-18cm below the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com