1-3nm monodisperse aerosol generating system

An aerosol generation and monodisperse technology, applied in material separation, material analysis, colloid chemistry, etc., can solve the problems of inability to obtain strictly monodisperse aerosol, inability to obtain aerosol with uniform diameter, inability to generate aerosol, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention provides a 1-3nm monodisperse aerosol generating system. The principle, working process and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings:

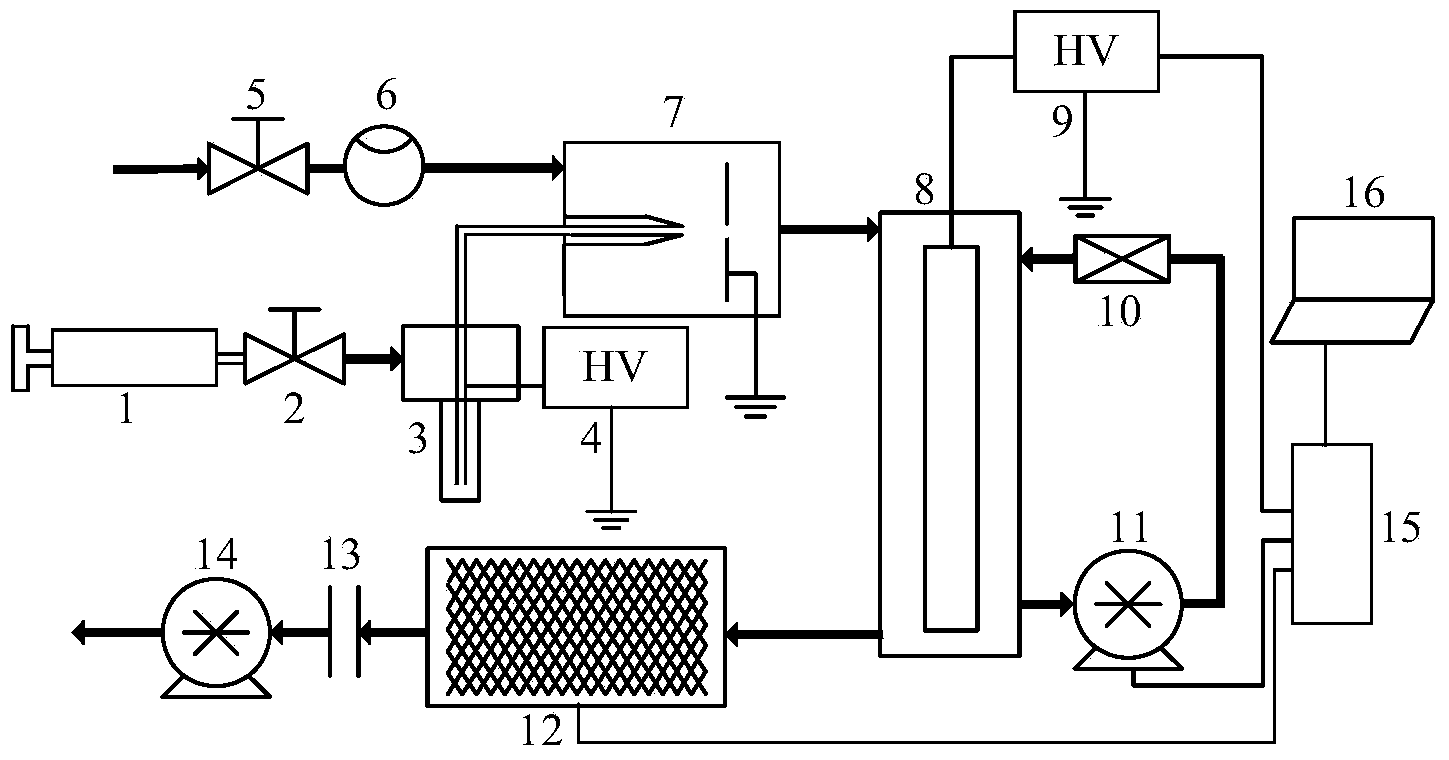

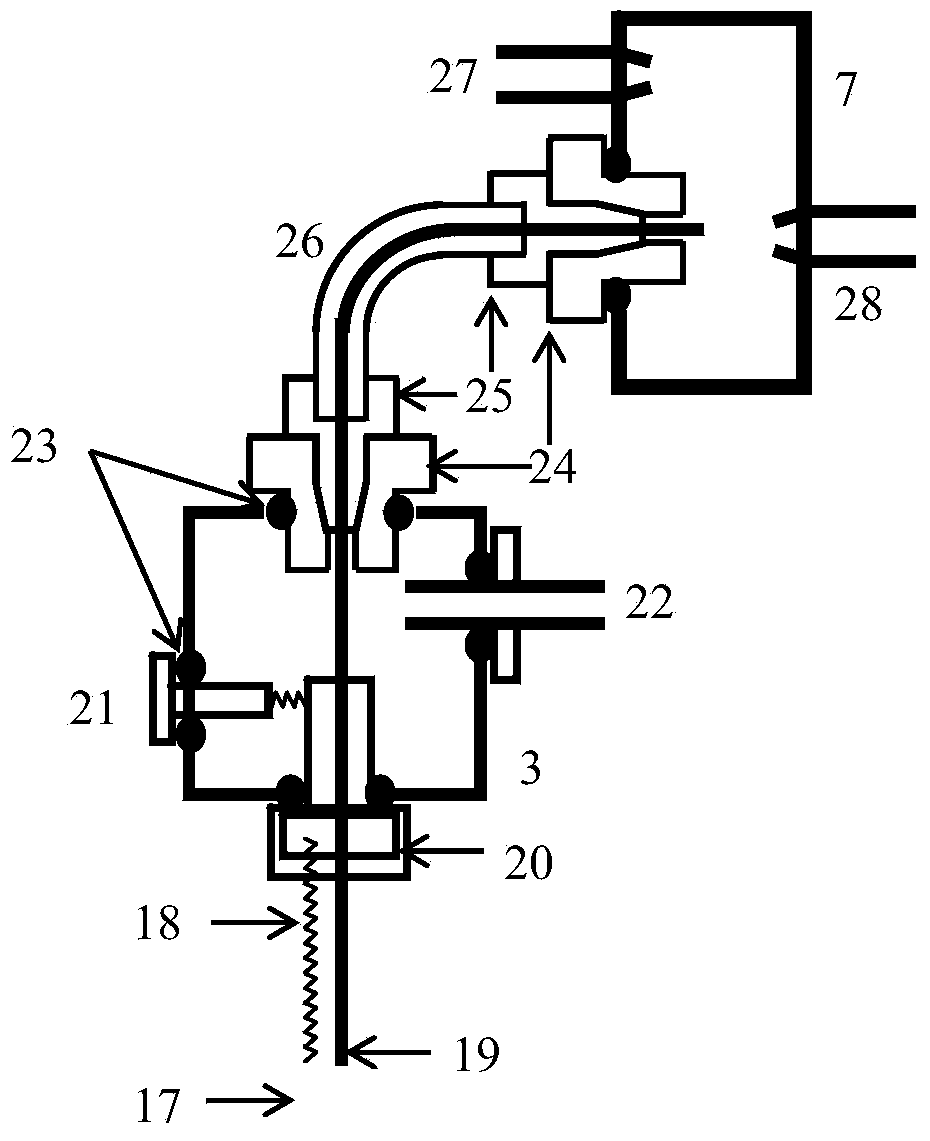

[0022] figure 1 It is a schematic diagram of a 1-3nm monodisperse aerosol generating system, which is mainly composed of an electrospray generator, a high-resolution differential mobility analyzer (HRDMA) 8 and an aerosol electrometer 12 . Among them, the structure of the electrospray generator is as follows figure 2 shown.

[0023] The 50mL syringe 1 and its syringe valve 2 are connected through a hose, the syringe valve 2 and the electrospray generator are connected to the electrospray connection chamber 3 through the syringe connection port 22, and the electrospray needle 19 can be adjusted by using the syringe 1 and the syringe valve 2. solution flow rate. The electrospray connection chamber 3 (18mm×25mm×20mm) is made of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com