Piezoelectrically-driven spraying direction flexible adjustment device

A technology of ejection direction and piezoelectric drive, applied in the direction of ejection device, etc., can solve the problem of low response frequency of two-dimensional motion platform and unable to fully utilize the frequency characteristics of piezoelectric ejector device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

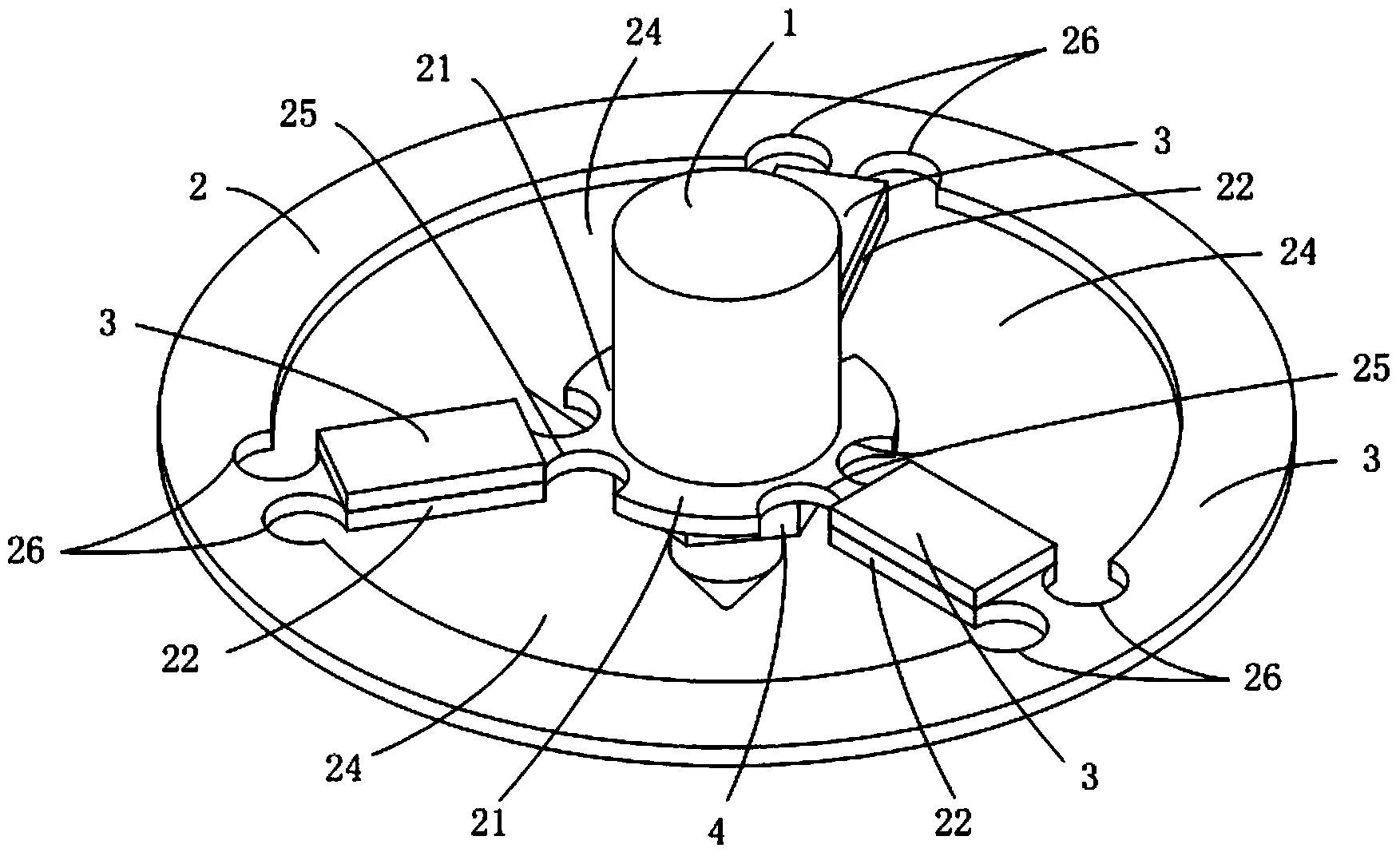

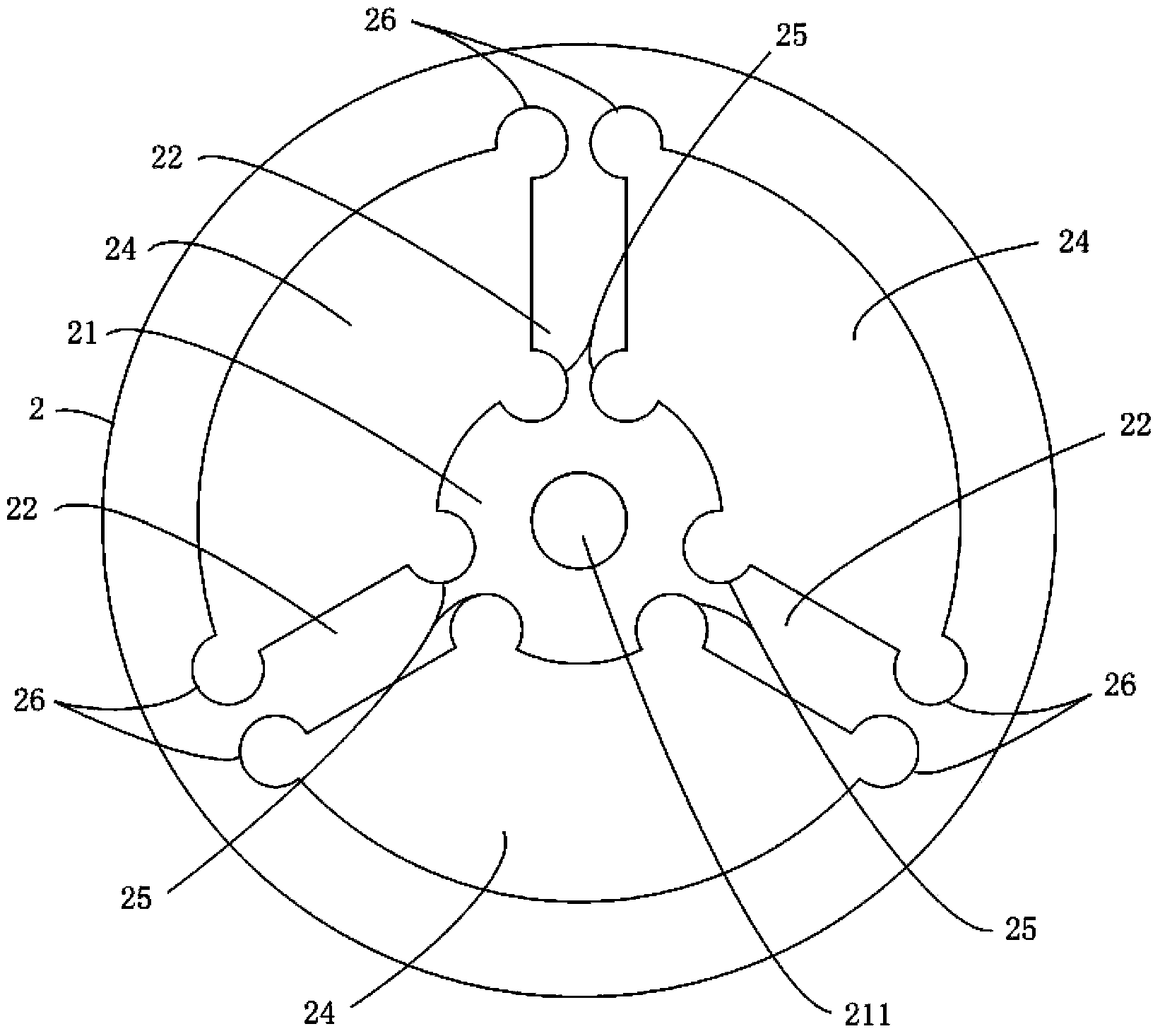

[0011] refer to figure 1 and figure 2 , the flexible adjustment device of the piezoelectric-driven injection direction of the present invention is used to adjust the injection direction of the injection head 1, the installation surface 21 of the nozzle formed by the elastic thin plate 2 and the piezoelectric material sheet 3, the cantilever deformation area 22 and the installation support area 23 constitute. Wherein the geometric center of the elastic substrate 2 is arranged with a circular spray head installation hole 211, the spray head 1 passes through the installation hole 211 and is fixed in the middle of the piezo-electrically driven spray direction flexible adjustment device by the nut 4, around the spray head installation hole 211 The area where the material is not removed forms the nozzle installation surface 21. After the nozzle head 1 is installed, the central axis of the nozzle 1, that is, the injection direction, is parallel to the normal direction of the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com