Threaded hole drilling and tapping machine

A tapping machine and threaded hole technology, which is applied in the field of special drilling and tapping machines for installing threaded holes in passenger car seats, can solve the problems of low processing efficiency, poor processing quality, small working space, etc., and improve processing quality and stability , Easy to manufacture and use, stable working process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

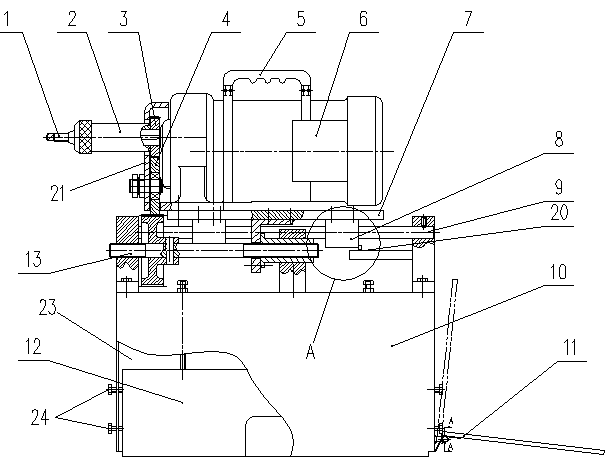

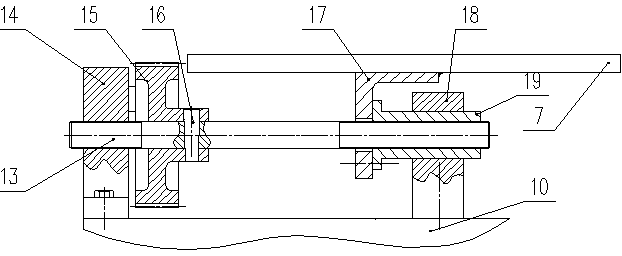

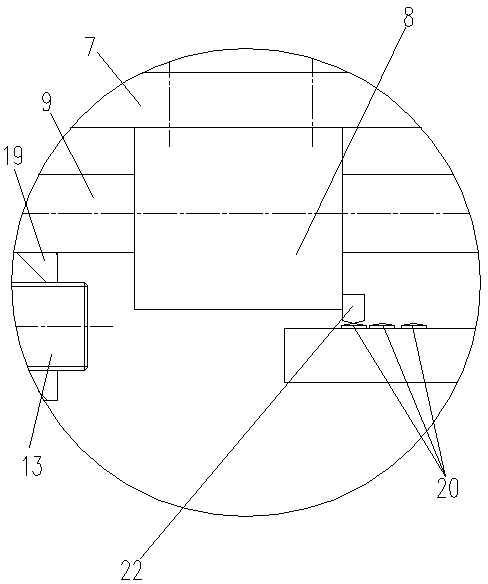

[0024] In the present invention, the drilling direction of the drilling and tapping composite tool is forward, and the reverse is backward.

[0025] Such as figure 1 with figure 2 As shown, the threaded hole drilling and tapping machine of the present invention includes a frame 10, a linear guide 9 is arranged on the top of the frame 10, two linear bearings 8 are installed at intervals on the linear guide 9, and the top of the two linear bearings 8 is connected with a coupling Steel plate 7, single-phase two-speed micro-speed motor 6 is installed on the connecting steel plate 7, the output shaft of the single-phase two-speed motor 6 is installed with an extended tool holder 2, and the front end of the extended tool holder 2 is equipped with a drilling and tapping compound tool 1; The output shaft of the single-phase two-speed motor 6 is connected with a differential screw mechanism through a gear transmission mechanism, and the differential screw mechanism is arranged on the fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap