A torque control method for an intelligent electric torque wrench

A torque wrench and torque control technology, applied in the direction of wrenches, manufacturing tools, screwdrivers, etc., can solve the problems of large torque control fluctuations, unreliable torque control methods, and inability to grasp the exact torque value of the wrench, so as to improve control accuracy and stability. Good, strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

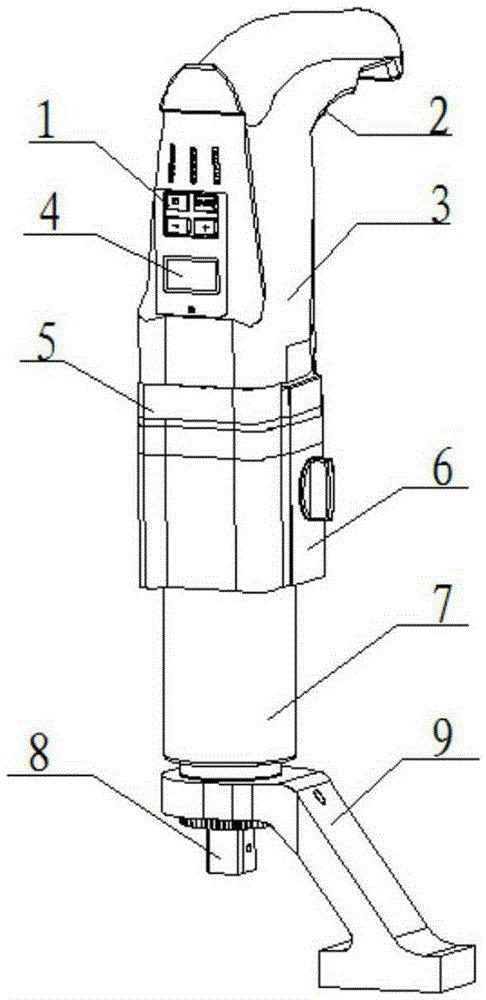

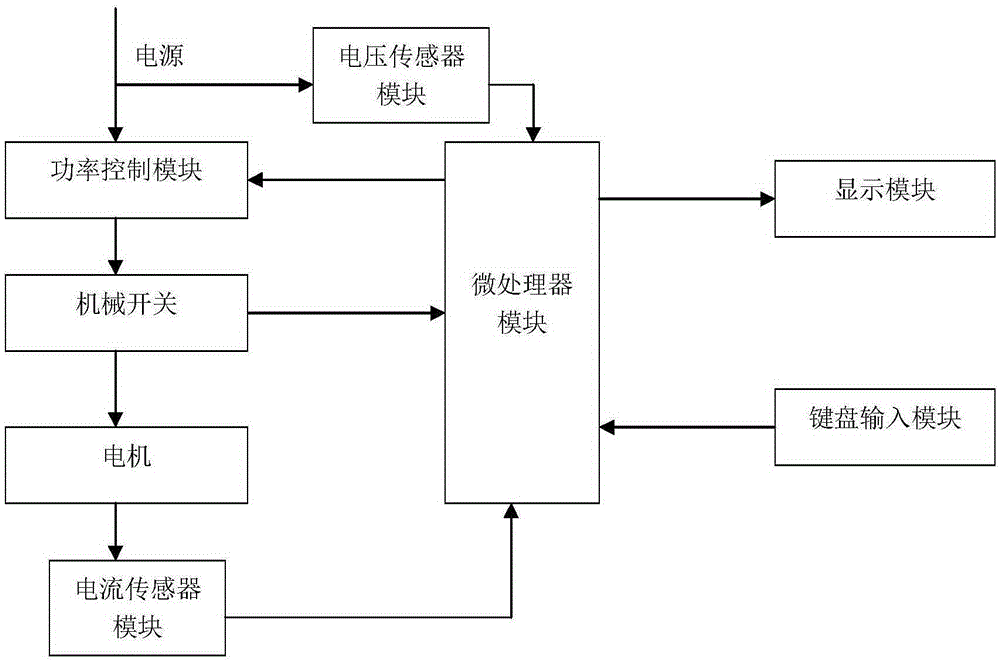

[0034] figure 1 It is a structural schematic diagram of an intelligent electric torque wrench according to this embodiment, and the electric torque wrench includes a torque control system (such as figure 2shown), the torque control system includes a power supply, a voltage sensor module, a power control module, a mechanical switch, a motor, a current sensor module, a microprocessor module, a display module and a keyboard input module, wherein: the microprocessor modules are respectively Connect with the voltage sensor module, power control module, mechanical switch, current sensor module, display module, and keyboard input module, the keyboard input module is used to determine the required torque value, and the required torque value is displayed on the display module , the voltage sensor module is connected between the power supply and the microprocessor module, the voltage sensor module is used to collect the voltage signal of the power supply, the torque-power relationship ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com