Modular rubber track wheels

A rubber crawler, modular technology, applied to crawler running gear, modular rubber track wheels. It can solve problems such as uneven distribution of ground pressure, difficulty in vehicle steering, and inability to meet load wheels, so as to enhance the ability to adapt to terrain changes, reduce the risk of wear and stripping, and improve ride comfort and passability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

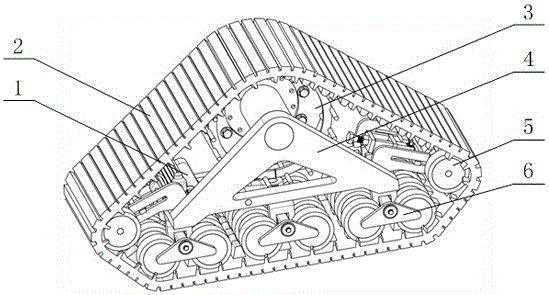

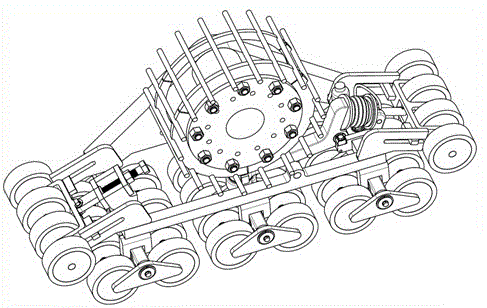

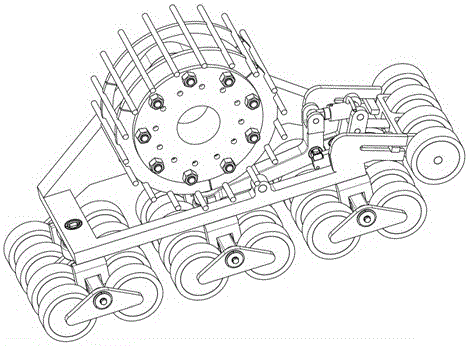

[0052] Such as figure 1 As shown, a modular rubber track wheel includes a frame 4, a modular driving wheel 3, a guide wheel system 5, a modular road wheel system 6, an independent swing arm suspension 1, and a rubber track 2. With a cantilever frame 4, the modular driving wheel 3 is installed above the frame 4; the guide wheel system 5 is installed on one side or both sides of the frame 4; the modular road wheel system 6 is installed under the frame 4, if the configuration includes the middle road wheel When assembled, it is connected to the frame 4 through an independent swing arm suspension 1; the rubber track 2 adopts a coreless gold structure, and rotates around the modular driving wheel 3, the guide wheel system 5 and the modular road wheel system 6; the rubber track 2 adopts a positive driving form , the driving angle on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com