Heavy metal zero discharge system of electroplating rinse water, and recovery method of rinse water

A technology for rinsing water and heavy metals, applied in chemical instruments and methods, light water/sewage treatment, water/sewage multi-stage treatment, etc. Pollute the environment, reduce operating costs, and be beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Take the rinse water recovery system of a chrome plating production line as an example:

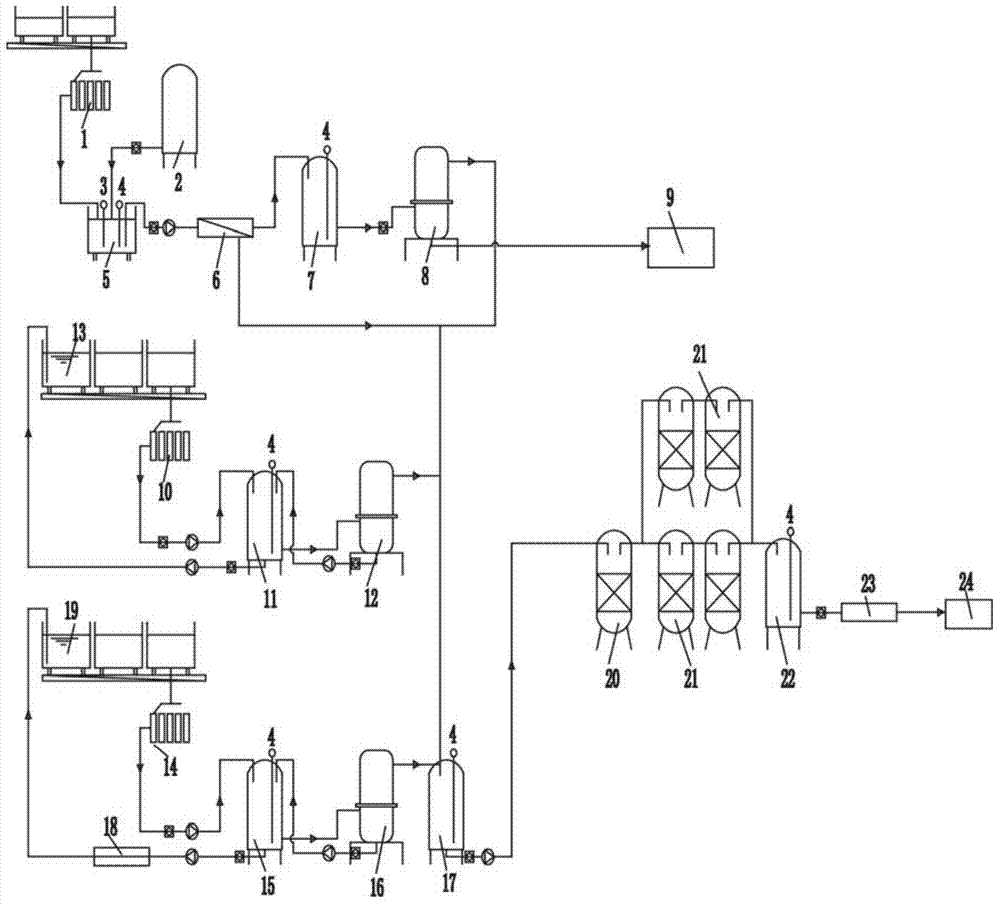

[0045] Such as figure 1 As shown, it includes a pre-treatment rinse water treatment system, a nickel rinse water treatment system and a chromium rinse water treatment system arranged side by side, and the pre-treatment rinse water treatment system is used for rinsing, neutralization, filtration and evaporation of the pre-treatment rinse water Afterwards, the evaporated dope is discharged into the sewage treatment station 9, and the flash water produced in the evaporation process and the ultrafiltration water produced by filtration are discharged into the collecting device; the nickel rinse water treatment system and the chromium rinse water treatment system are respectively used After rinsing and evaporating with the respective rinsing water, the evaporated concentrated liquid is recovered separately, and the flash water generated during the evaporation process is discharged into t...

Embodiment 2

[0071] Take the rinse water recovery system of the galvanizing production line as an example:

[0072] The difference between this embodiment and Embodiment 1 is that the rinse water recovery system of the galvanizing production line only includes a pre-treatment rinse water treatment system and a zinc rinse water treatment system, and does not require an intermediate rinse water treatment system. Nickel, so galvanizing omits a process step compared with chrome plating in the treatment process.

[0073] The invention is mainly used for chrome plating, cadmium plating, zinc plating, cyanide electroplating and other highly harmful heavy metal plating species.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap