Polycarbonate process wastewater treatment method

A technology of polycarbonate and wastewater treatment, which is applied in natural water treatment, extraction water/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems of large amount of organic solvent and high cost of wastewater treatment, and achieve low cost and easy industrialization The effect of magnification and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

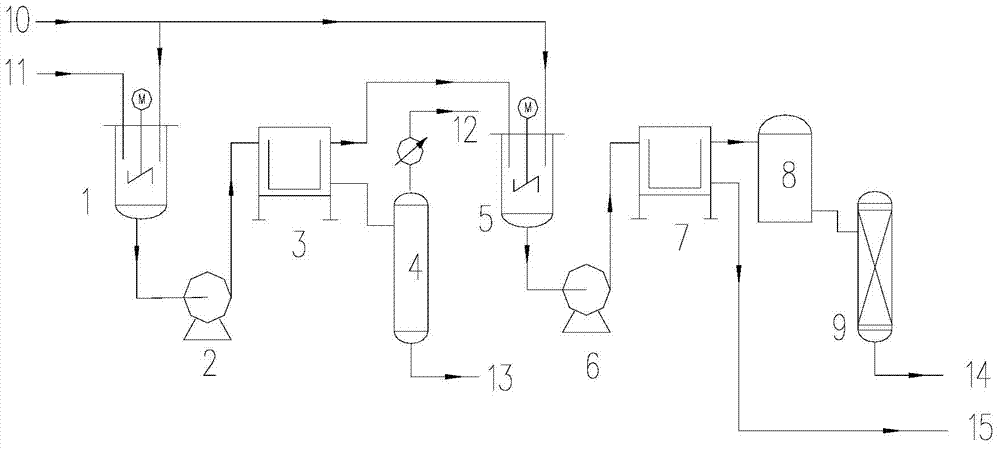

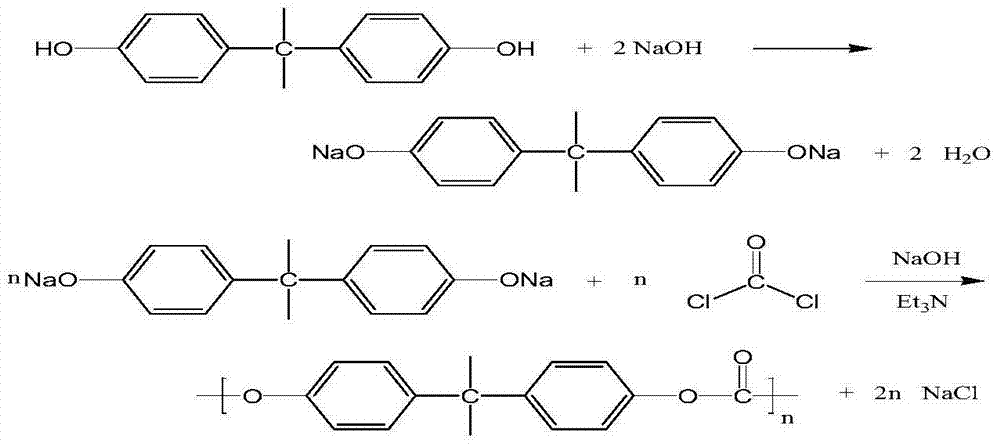

[0019] The measured wastewater composition is NaCl 5%, bisphenol A 395mg / L, phenol 0.25mg / L, N content 350mg / L, COD 7800mg / L, and wastewater pH value of about 10.2. According to the above method at room temperature, 1000ml of waste water is sent into the mixing tank 1 from the primary waste water inlet 11. After the waste water and the inflowing extractant dichloromethane 70ml are in continuous countercurrent contact under sufficient stirring conditions, they are sent to the centrifuge 3 by the peristaltic pump 2 for centrifugation, and then sent to the mixing kettle 5, and the fresh solvent dichloromethane 30ml (including additional The fresh solvent dichloromethane and the solvent dichloromethane evaporated by the evaporator) are fully mixed, and then pumped to the centrifuge 7 by the peristaltic pump 6 for centrifugation, the bisphenol A of the obtained wastewater is reduced to 12mg / L, and the phenol is 0.005mg / L, COD value is 800mg / L. Then use 25g of polystyrene resin fo...

Embodiment 2

[0021] refer to figure 1 The process and equipment shown, the measured wastewater composition is NaCl14%, bisphenol A975mg / L, phenol0.23mg / L, N content 500mg / L, wastewater COD value 9600mg / L, pH value 10.6. With the method of Example 1, the waste water (1000ml) of polycarbonate was extracted by two-stage continuous countercurrent. According to the above method at room temperature, 1000ml of waste water is sent into the mixing tank 1 from the primary waste water inlet 11. After the waste water and the inflowing extractant 1,2-dichloroethane 50ml are continuously countercurrently contacted under sufficient stirring conditions, they are sent to the centrifuge 3 by the peristaltic pump 2 for centrifugation, and then sent to the mixing tank 5, and fresh solvent 1,2 - 30ml of dichloroethane (including added fresh solvent 1,2-dichloroethane and solvent 1,2-dichloroethane distilled by the evaporator) is fully mixed, and then pumped to the centrifuge by peristaltic pump 6 7 is centri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com