Long-acting luminous paint and its preparation method

A luminous paint, long-lasting technology, applied in the field of coatings, to achieve the effect of reducing renovation, simple and easy control of equipment and control conditions, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] After premixing 50 parts of acrylic resin, 1.5 parts of bentonite, 3 parts of butyl acetate and 7 parts of xylene, disperse at a high speed of 2000r / min for 30 minutes with a high-speed disperser, and then add 3 parts of toluene, 34.5 parts of luminous powder and 1 part of additives are used for coloring and viscosity adjustment. The viscosity needs to be adjusted to 150±10s (coating -4 cups / 25°), and finally the impurities in it are filtered to obtain long-lasting luminous paint. Among them, the additives are luminous powder additives, defoaming agents and anti-settling agents. The particle size of the added luminous powder is 5~8μm, and the afterglow time is longer than 12h.

Embodiment 2

[0022] After pre-mixing 52 parts of acrylic resin, 1.8 parts of bentonite, 2.8 parts of butyl acetate and 7.2 parts of xylene, use a high-speed disperser to disperse at a high speed of 2000r / min for 30 minutes, and then add 2.8 parts of toluene, 34 parts of luminous powder and 1.2 parts of additives are used for coloring and viscosity adjustment. The viscosity needs to be adjusted to 150±10s (coating -4 cups / 25°), and finally the impurities in it are filtered to obtain long-lasting luminous paint. Among them, the additives are luminous powder additives, defoaming agents and anti-settling agents. The particle size of the added luminous powder is 8~12μm, and the afterglow time is longer than 12h.

Embodiment 3

[0024] After premixing 48 parts of acrylic resin, 1.4 parts of bentonite, 3.2 parts of butyl acetate and 6.8 parts of xylene, disperse at a high speed of 2000r / min for 30 minutes with a high-speed disperser, and then add 3.2 parts of toluene, 33.5 parts of luminous powder and 0.9 parts of additives are used for coloring and viscosity adjustment. The viscosity needs to be adjusted to 150±10s (coating -4 cups / 25°), and finally the impurities in it are filtered to obtain long-lasting luminous paint. Among them, the additives are luminous powder additives, defoaming agents and anti-settling agents. The particle size of the added luminous powder is about 10 μm, and the afterglow time is longer than 12 hours.

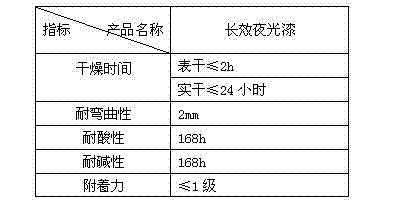

[0025] The main technical indicators of the luminous paint made by any of the above embodiments all reach the data shown in the table below:

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com