Photo-curable polysiloxane polyurethane (methyl) acrylate composition, adhesive and cured product

A polysiloxane polyurethane, acrylate technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of easy peeling, high volume shrinkage, and achieve the best penetration, The effect of resistance to strong light exposure is not easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

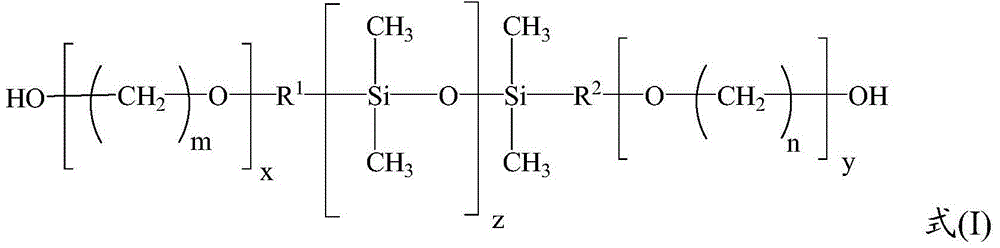

Method used

Image

Examples

Synthetic example 1

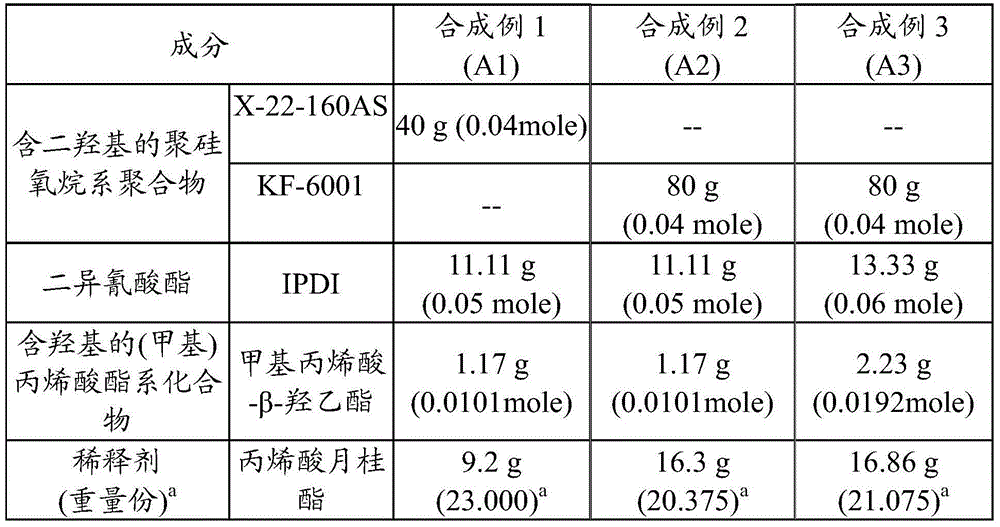

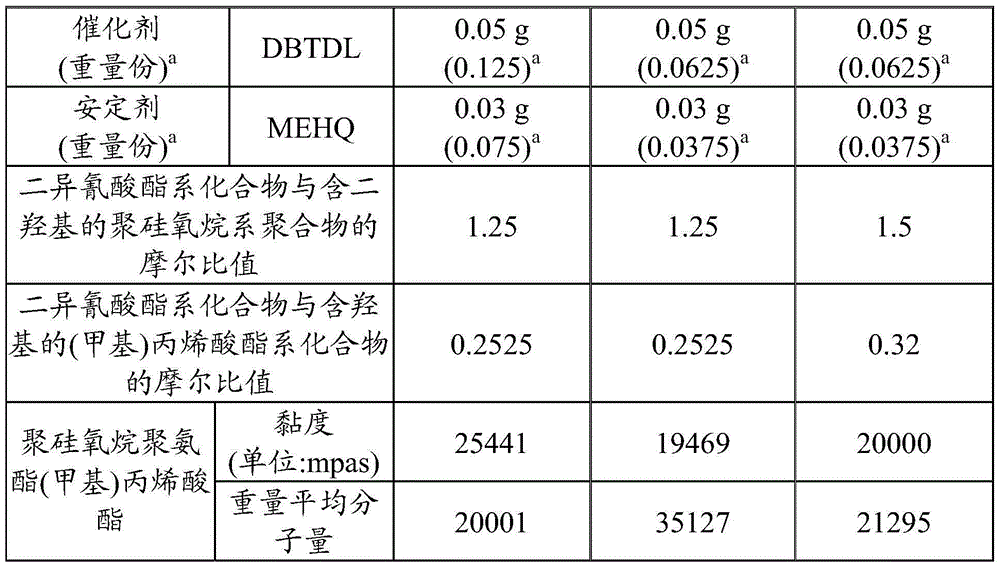

[0070] [Synthesis Example 1] Synthesis of polysiloxane urethane (meth)acrylate (A1)

[0071] Place 11.11 grams (0.05 moles) of IPDI, 40 grams (0.04 moles) of X-22-160AS, 9.2 grams of lauryl acrylate and 0.05 grams of DBTDL in a 600-milliliter round-bottomed bottle, and continue at 40°C under a nitrogen atmosphere. Stir the reaction for 1.5 hours, then add 0.03 grams of MEHQ and 1.17 grams (0.0101 moles) of β-hydroxyethyl methacrylate, and react at 65 ° C for 4 hours to obtain polysiloxane polyurethane methacrylate , the viscosity is 25441mpas, and the weight average molecular weight is 20001.

[0072] [Synthesis Examples 2 to 3]

[0073] The polysiloxane urethane (meth)acrylates of Synthesis Example 2 and Synthesis Example 3 were prepared in the same manner as in Synthesis Example 1, wherein the types and amounts of each component are shown in Table 1.

Embodiment 1

[0074] [Example 1] Preparation of photocurable polysiloxane polyurethane (meth)acrylate composition

[0075] Stir and mix 81 grams of polysiloxane urethane methacrylate of Synthesis Example 1, 17.9 grams of lauryl acrylate, 0.4 grams of I819 and 0.7 grams of TMMP at 25° C. After machine defoaming, the photocurable polysiloxane polyurethane (meth)acrylate composition can be obtained. Various property tests were carried out, and the test results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com