Assembling device of continuous beam pier construction support

A technology for assembling devices and supporting frames, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., which can solve the problems of wasting resources and increasing the labor of welding workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

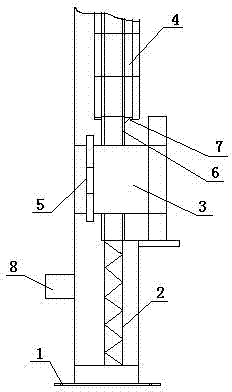

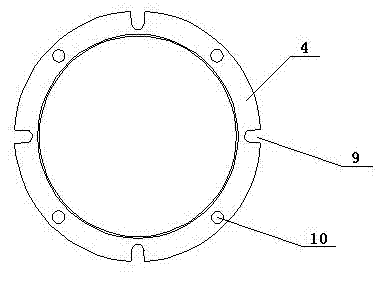

[0009] The hydraulic system 1 is installed on the base 2, the base 2 is relatively wide and firm, the upper end of the hydraulic system 2 is equipped with a platform 3, and a spare platform is set on one side of the platform 3, and a moving mechanism 5 is set on the spare platform, and the platform moves The mechanism 5 is driven by hydraulic pressure, and a plurality of support tube units 4 are vertically arranged on the upper end surface of the platform 3, and the plurality of support tube units 4 form a support tube, and the two ends of the support tube unit 4 are processed with bolt holes 10, through which bolt holes 10 are used. Bolts connect the support pipe unit 4 in the axial direction, guide grooves 9 are provided on the upper end surface and the lower end surface edge of the support pipe unit 4, the guide grooves 9 of the adjacent support pipe units 4 are facing each other, and guide rods are arranged in the guide groove 9 6. The lower end of the guide rod 6 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com