A construction method of vip vacuum board applied to building wall insulation

A construction method and a technology for building walls, which are applied in the field of building energy conservation and heat preservation, can solve problems such as high loss rate, and achieve the effects of reliable quality, simple technology, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

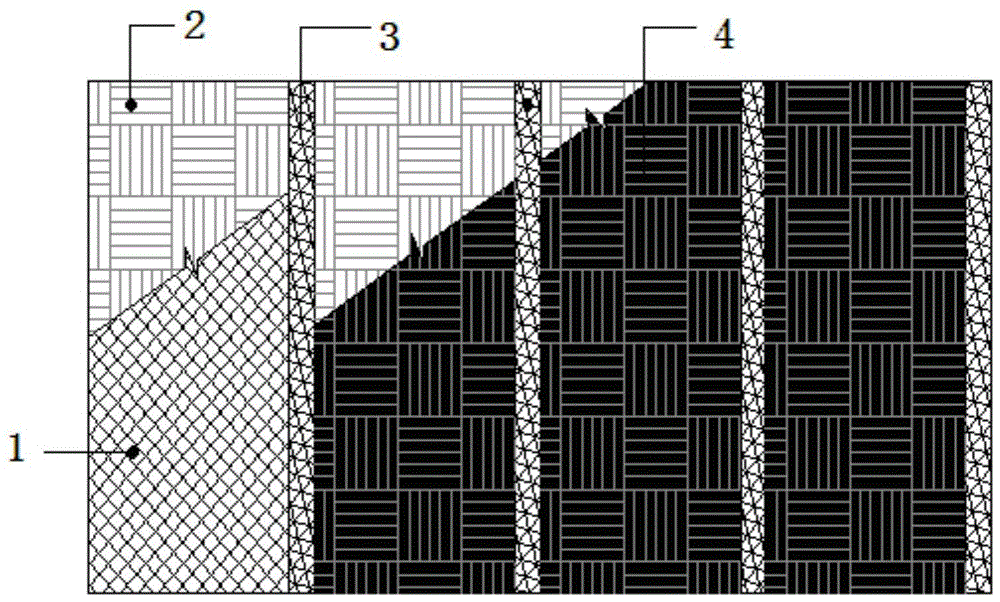

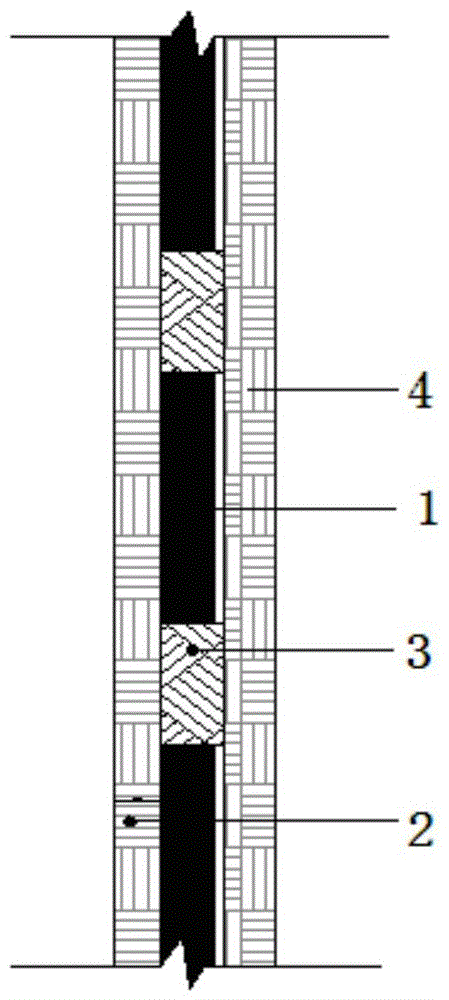

[0028] 1. Fix the basic Ozon board

[0029] The base-level Ozon board is fixed on the wall with a thickness of 9mm, which plays the role of protecting the VIP vacuum insulation board and fixing the Ozon board slats. The surface of the sticking part of the VIP vacuum insulation board is required to be smooth.

[0030] 2. Install OSB slats

[0031] The width of the pine board slats is 3-4cm, and the slats should be smooth and free of burrs. They are used to fix the final closed pine board, and are fixed to the grassroots pine board with gun nails according to the width of the VIP vacuum insulation board.

[0032] 3. Paste the VIP vacuum insulation panel

[0033] The thickness of the VIP vacuum insulation board is 10mm, and it is pasted between the slats of the Ozon board. During the pasting process, it should be squeezed evenly and fixed with the palm of your hand. Do not touch with your fingertips to avoid piercing the VIP board; the insulation board should be pasted Firm, no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com