Vertical-axis wind turbine with flow collection blades and low gravity center

A vertical axis, low center of gravity technology, applied in the field of wind power generation equipment, can solve the problems of reducing the weight of the wind rotor, large airflow interference, low strength and stiffness, etc., to achieve the effect of reducing the weight of the wind rotor, avoiding interference with the airflow, and increasing the probability of facing the wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

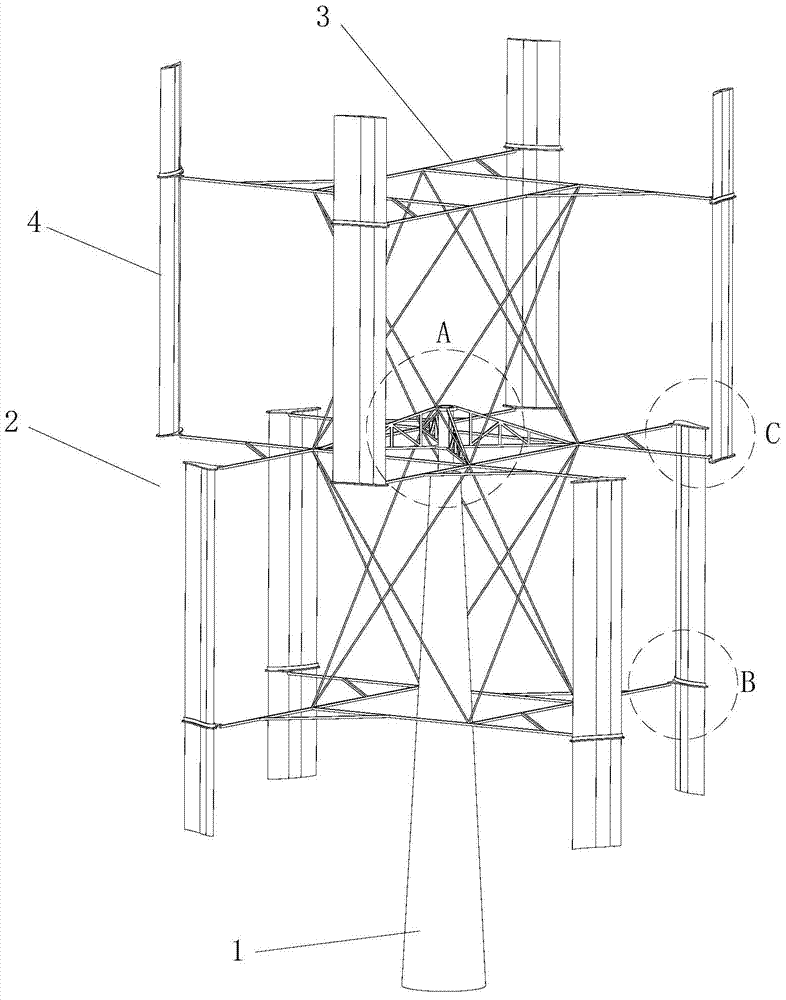

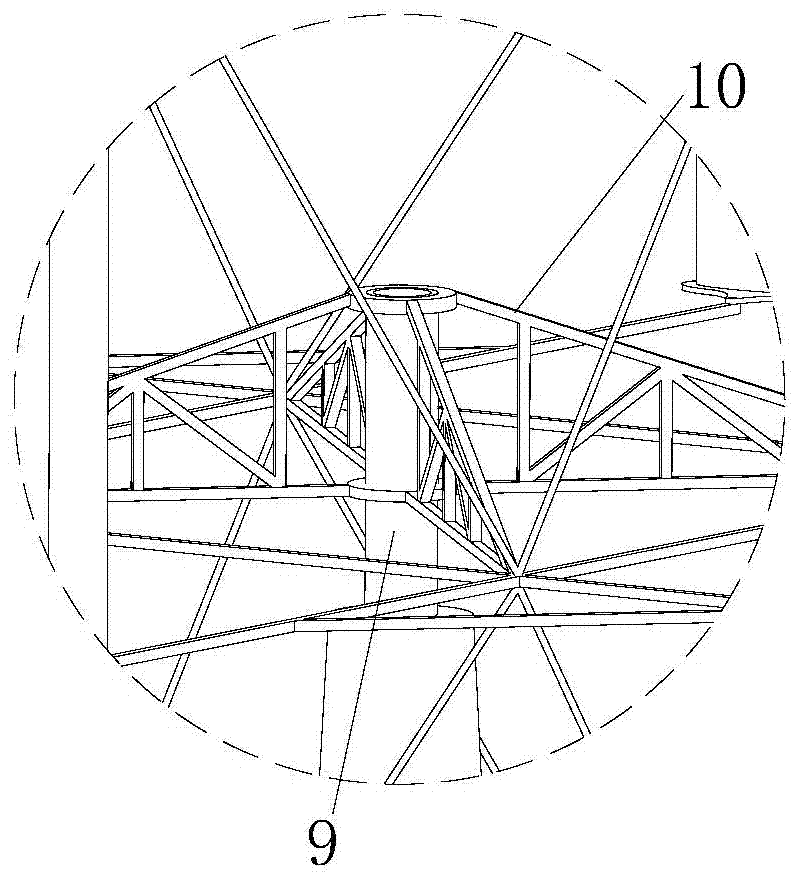

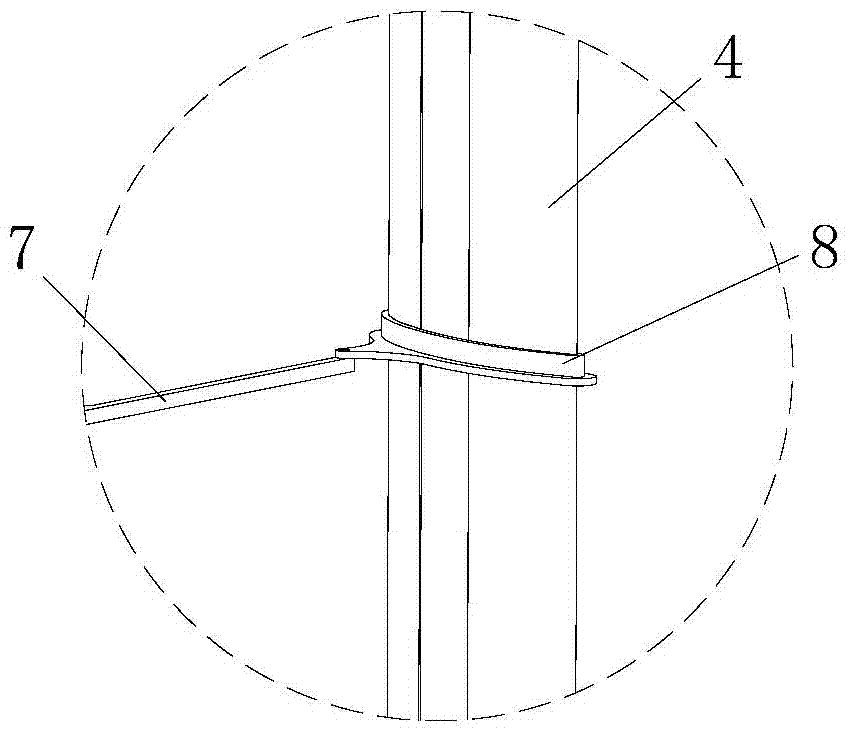

[0057] The low center of gravity vertical axis wind turbine with collector blades in this embodiment is as follows: Figure 1 to Figure 4 As shown, it includes a fixed tower 1 that determines the vertical axis of rotation and a wind wheel 2 supported on the tower 1, and the wind wheel 2 and the tower 1 constitute a horizontal rotation pair that is axially constrained; the wind wheel 2 includes a center of rotation supported on The wheel frame 3 of the tower 1, and the collecting blades 4 distributed on the periphery of the wheel frame 3; as Figure 12 to Figure 14 As shown, the collecting blades 4 are composed of a group of fins 5 arranged in parallel with gaps between them. The collecting blades 4 extend vertically and have a streamlined cross-section; And the spokes corresponding to the upper and lower are constituted, and the outer ends of the spokes corresponding to the upper and lower are respectively rotatably connected with the corresponding upper and lower parts of the...

Embodiment 2

[0064] The low center of gravity vertical axis wind turbine with collector blades in this embodiment is as follows: Figure 15 to Figure 16 As shown, its basic structure is the same as that of Embodiment 1, and the only difference is that: between the side of the fixing member 8 facing the transmission frame 6 or the connection frame 7 and the spokes of the transmission frame 6 or the connection frame 7, there is a device for rotating the blade angle. A telescopic controller 12, the controller 12 is an elastic component, or the controller 12 is an electric controller connected to an external control device at the controlled end.

[0065] The controller 12 can be an elastic member, and its length can change or return when an external force is applied or withdrawn; The rotation connection point of the connection frame 7 is a certain angle of axis rotation, so that the controller 12 is extended or shortened, thereby changing the effect of the air flow on the blades, which in turn...

Embodiment 3

[0069] The low center of gravity vertical axis wind turbine with collector blades in this embodiment is as follows: Figure 17 , 18 As shown, compared with Embodiment 1, the wheel frame structure is different: the top of the tower 1 is rotationally connected with the power input shaft 13 of the load, and the axis of the power input shaft 13 is arranged vertically; The third flange 10-6, the third flange 10-6 is fixedly connected with the power input shaft 13; the third flange and the top of the tower form an axially restrained horizontal rotation pair.

[0070] Specifically, the middle part of the transmission frame 6 is a regular polygon and is provided with a truss 10; the truss 10 includes a third flange 10-6, the third flange 10-6 is fixedly connected with the power input shaft 13, and the third flange 10- 6 circumferentially evenly distributed load-bearing arms 10-3 radially extending, the ends of the load-bearing arms 10-3 are respectively connected with the vertices of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com